What is Prototype PCB Assembly

Prototype PCB assembly refers to the experimental stage after PCB design to prove the feasibility of the design and detect any potential problems. In addition, at this stage, manufacturers can analyze the advantages and disadvantages of the board, and provide reference for making more versions in the future. Manufacturers will Prototype PCB assembly is seen as a very important step in the PCBA manufacturing process, as it allows them to get a snapshot of the entire process and eliminate errors before a full production run to ensure everything works as expected when it comes to mass production.

Benefits of Prototype PCB Assembly

Compared with direct mass production, prototype PCB assembly has several benefits, in this part, we will discuss them one by one:

Detect errors early: PCBA prototyping lets manufacturers find errors on boards early on, so they can improve and fix problems before investing a lot of time and money in unworkable solutions. And, the sooner they find problems, The less time and cost it takes to make everything go smoothly.

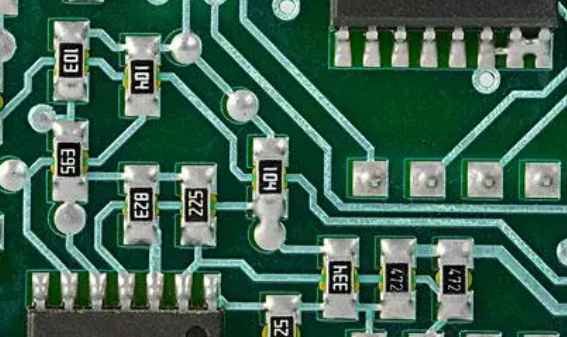

Testing components individually: Prototyping enables manufacturers to perform multiple tests to check the functionality of different components individually. This is especially useful when complex circuit boards involving various components are involved, and testing them individually can pinpoint where problems may arise . Without this, it's hard to figure out what the problem is.

Efficient project completion: Using PCBA prototypes is beneficial for early detection of design flaws and quick identification of components that need to be adjusted. If problems are found during mass production, it will take a lot of time and lead to longer project completion time. In addition, ensure that the prototyping stage Design feasibility reduces batch rework issues and facilitates efficient completion of the overall project.

Reduce overall cost: Prototype PCB assembly helps to significantly reduce the overall project cost, because all potential problems can be found and solved at this stage. It is known that the rework cost of PCBA prototype is much lower than the rework cost of mass production, on the other hand, at the beginning It is easier and less time-consuming to troubleshoot problems at the prototype stage before mass production.

Improve the final product: High-quality PCBA prototypes can give you a very accurate estimate of mass production results, because they represent the performance of the final product well. In addition, suppliers can improve the PCB and components based on the problems found in the PCBA prototype The performance of the device, thereby improving the quality of the final product.

Prototype PCB Assembly Process

Prototype PCB assembly is a six-step process, and each step requires care to ensure it works as intended. These steps include:

Material selection: In the beginning, manufacturers need to choose materials for PCBA prototypes. Generally, they will choose plastic, which is the first choice for PCBA prototype manufacturing. Since this material is easy to use, it is easy to fold and shape.

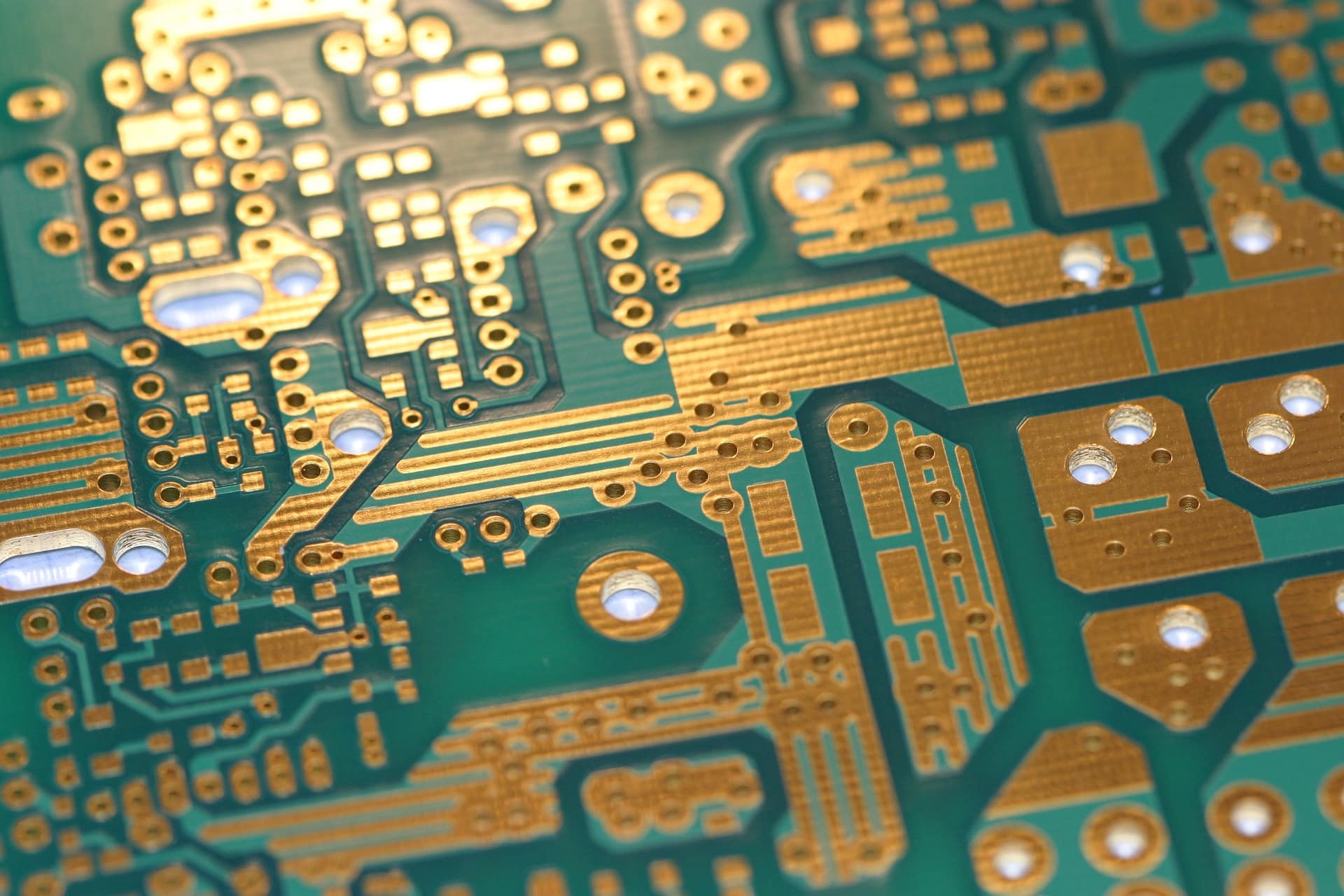

Quick Design: This step is done on the stencil, and the location of the components and connection traces are confirmed in the Quick Design stage.

Test Design: In this step, the manufacturer aims to test the functionality of the design, they will check that the placement and connection of the components are properly designed.

Rectification and redesign: If any errors are found in the design, then the PCB manufacturer will carry out rectification and redesign. They may need to redesign the prototype with new connection traces on the template to ensure the performance of the prototype.

Rapid Prototyping: This step involves prototyping. The whole process can be done quickly using a template, with all the components mounted in the exact position of the board, as designed by CAD software.

Functional testing: The last step is aimed at testing the functions of the finished PCBA prototype. If all functions work as expected, then the manufacturer will move to the next step - mass production.