1. In PCB design, it is required to choose DC/DC or LDO for power chip design.

First, to put it simply, in booster occasions, of course, only DC/DC can be used, because LDO is a pressure drop type, which cannot be boosted.

When the design of the circuit for the shunt power supply has the following requirements

1. High noise and ripple suppression;

2. Occupy small PCB board area, such as mobile phone and other handheld electronic products;

3. Inductors are not allowed in the circuit power supply, such as mobile phones;

4. The power supply shall have the function of instantaneous calibration and output state self-check;

5. Voltage regulator low voltage drop, low power consumption;

6. Low line cost and simple scheme are required;

At this point, LDO is the most appropriate choice to meet various requirements of product design.

Second, in addition, we need to look at the main characteristics of each:

DC/DC: high efficiency, high noise; The advantage is that the conversion efficiency is high, can be large current, but the output interference is larger, the volume is relatively large.

LDO: low noise, low static current; Small volume, small interference, when the input and output voltage difference is large, conversion efficiency is low.

Therefore, if it is used in the case of large pressure drop, DC/DC is selected, because of its high efficiency, while LDO will lose a large part of its efficiency due to large pressure drop.

If the voltage drop is small, choose LDO because of its low noise, clean power supply, and simple peripheral circuitry at low cost.

LDO is the low dropout regulator, which means low voltage difference linear regulator, which is the opposite of the traditional linear regulator. Traditional linear voltage regulators, such as 78xx series of chips require that the input voltage is 2v~3V higher than the output voltage, otherwise it can not work normally. But in some cases, such conditions are obviously too harsh, such as 5v to 3.3v, input and output pressure difference is only 1.7v, obviously does not meet the conditions. In view of this situation, there is the LDO class of power conversion chip.

LDO linear step-down chip: The principle is equivalent to a resistance partial voltage to achieve step-down. The energy loss is large, and the lowered voltage is converted into heat. The greater the step-down pressure difference and load current, the more obvious the chip heating. The package of this kind of chip is relatively large, easy to heat.

LDO linear step-down chip such as: 2596, L78 series, etc.

DC/DC step-down chip: In the step-down process of energy loss is relatively small, chip heating is not obvious. Chip package is relatively small, can realize PWM digital control.

DC/DC step-down chip such as TPS5430/31, TPS75003, MAX1599/61,TPS61040/41

Generally speaking, in PCB design, the booster must choose DCDC. The step-down choice between DCDC and LDO should be compared in terms of cost, efficiency, noise and performance. The key is specific application specific analysis.

2.PCBA smt manufacturer: The difference between PCB and PCBA?

I believe that many people are not unfamiliar with PCB circuit boards and may often hear them in daily life, but they may know little about PCBA and may even be confused with PCB. So, what is a PCB? How did the PCBA evolve? What's the difference between PCBS and PCbas?

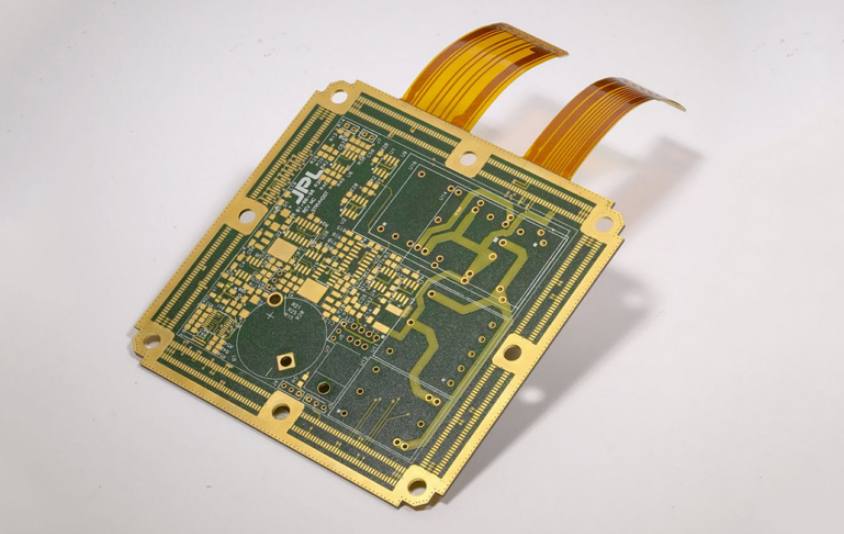

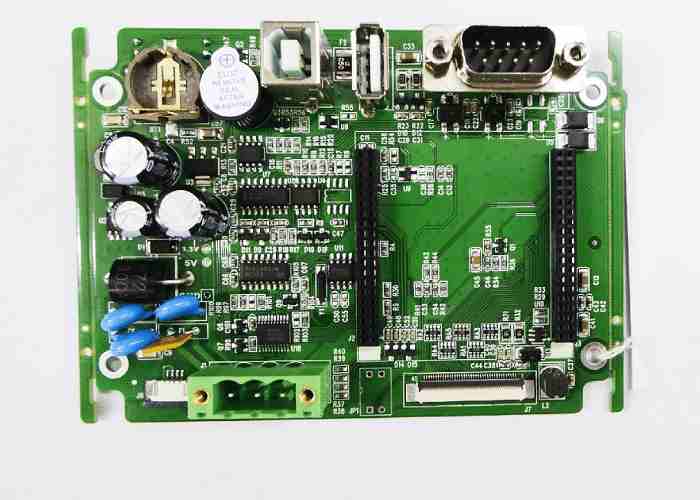

PCB is short for printed circuit board, because it is manufactured by electronic printing, so it is called "printed circuit board". PCB is an important electronic component in the electronic industry, is the support of electronic components, is the carrier of electrical connection of electronic components. Printed circuit board has been widely used in the production and manufacture of electronic products, its unique characteristics are summarized as follows: ".

1. High wiring density, small size, light weight, conducive to the miniaturization of electronic equipment.

2. It is conducive to mechanization and automatic production, improve labor productivity and reduce the cost of electronic equipment.

3. Due to the repeatability and consistency of graphics, wiring and assembly errors are reduced, and equipment maintenance, debugging and inspection time is saved.

4. Design can be standardized to facilitate communication.

PCBA is the abbreviation of printed circuit board + assembly, that is to say, PCBA is passed through PCB empty board SMT, then throughout the whole process of immersion.

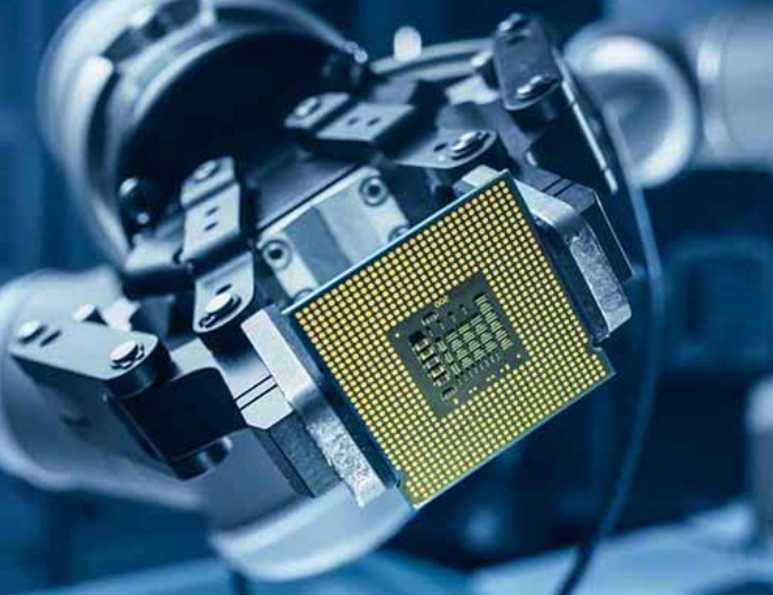

SMT is short for surface mount technology, mainly using assembly machine to install some small parts on PCB board, the production process is: PCB board positioning, printing solder paste, assembly machine installation, welding furnace and inspection.

A DIP is a "plug-in" that inserts parts into a PCB, integrating parts together in plug-in form when some parts are large and unsuitable for installation technology. Its main production process is: adhesive, plug-in, inspection, wave welding, brush plate and inspection.

From the above introduction, we can know that PCBA generally refers to a processing process, and can also be understood as a completed circuit board, that is to say, the process on the PCB board has been completed before being calculated as PCBA. A PCB, on the other hand, is a blank printed circuit board with no parts.

In a word, PCBA is finished board, PCB is bare board.

3. How to choose high-quality smt patch manufacturers?

Because there are so many smt manufacturers, enterprise customers will always be troubled when choosing. For this situation, today Xiaobian has made a survey summary, and the following will be shared with you, hoping to help friends who want to know where the high-quality smt manufacturers have them.

As we all know, the Pearl River Delta, especially Guangzhou, Shenzhen and other places have the largest number of electronic manufacturers. However, besides these places, there are also other places, such as the Yangtze River Delta, Bohai Rim and the mainland, where there are high-quality smt manufacturers. Therefore, in order to find high-quality manufacturers, we must follow the following points:

First, it does not matter whether the scale is large, the key is suitable

Before, many people misunderstood the choice of high-quality smt manufacturers, believing that as long as the scale is large, it must be good. This does have a great reference value, but it is not absolute, and large-scale SMT manufacturers may not be suitable for all corporate customers. On the one hand, some enterprise customers need to make small-batch sample orders, which do not need to find large-scale manufacturers. On the other hand, large-scale smt manufacturers often charge high fees, and the order quantity is large and the queuing time is long. Therefore, instead of this, it is better to directly choose suitable for their own enterprise production of smt manufacturers. Although the scale of these manufacturers is not as large as the processing plant, but they each have their own advantages, each has their own strengths, and their good fields are targeted, suitable for specific production enterprises.

Two, excellent is not excellent, look at the equipment

High-quality smt manufacturers are generally divided into two kinds, one is to take high-end precision route, the other is to take low-end cheap route. The former is often large-scale, large input processing plant, the latter is more in small workshops, individual entrepreneurship, only the machine, not many employees, equipment is relatively old do not say, there is no warehouse pipe, more no quality assurance, only boot and play two kinds of operation, very simple, the price is also very cheap. Of course, the quality of such a small workshop is difficult to guarantee, if it is a high precision added value of the board, must not choose this, otherwise it will regret.

Three, choose not to choose to see the degree of professional cooperation

As an important part of electronic products, the professional cooperation of smt manufacturers determines whether the circuit board can be delivered on schedule, how much repair rate and how much product quality rate. Therefore, if you want to find high-quality smt manufacturers, you must find a high degree of professional cooperation. So, how to judge the degree of professional cooperation? We can observe the attitude and philosophy of SMT manufacturers by talking with their management, bosses and employees, learn about their market reputation through the third party, and learn about their services through the customers we have served.

Four, quality management

In addition to the above three points, there is another important point is to judge whether the manufacturer is excellent basis, that is, quality management. At present, in order to attract customers, some SMT processing plants will attract customers' attention and sign orders with low prices. However, in order to ensure their own profits, they will find a balance from other aspects, such as reducing QC personnel, not equipped with AOI and other detection means, which will lead to the quality of circuit boards will be reduced.

Therefore, when choosing high-quality smt manufacturers, we must pay attention to the fact that only comprehensive understanding can ensure the perfect processing of products, improve the performance and service life of products, and gain favorable market.