Explanation and analysis of PCB design and micropore

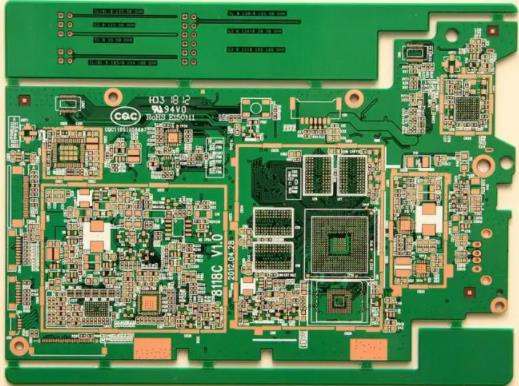

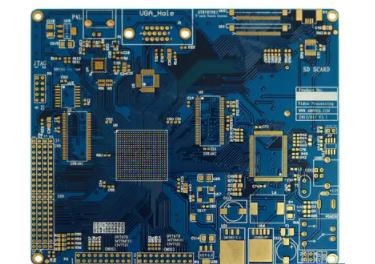

Thanks to all technological innovations, printed circuit boards are becoming smaller and smaller. With high-density interconnecting PCBs and micropores, they can be placed more in smaller spaces.

Although micropores have existed for many years, they become more and more common when multiple functions need to be controlled by a single circuit board. Microwell routing between layers makes it easier to include all the necessary functions.

Since all functions can be completed on one board, it can help to save equipment space and reduce some weight. Although such light weight reduction may not be important for some types of equipment, it may be important for equipment designed for the aerospace industry or military equipment.

What is micropore?

This is a much smaller version of the traditional through-hole. It is considered to be micro, and most people believe that the diameter needs to be less than 150 microns (µ m). These holes can be drilled by laser or mechanical methods. Laser is a preferred method for drilling these holes because of its accuracy. Some can be as small as 15 microns.

Another advantage of laser is that it will not leave any residues or materials in the borehole, which may happen to mechanical drills. Laser also tends to have fewer defects. However, quality manufacturers who know and understand how to drill holes mechanically and correctly also rarely fail.

Today, there are several different types of micropores. Regardless of the type, you will find that they all have two common characteristics that need to be considered. They will have a low aspect ratio and may have a risk of neck fracture. This fracture may occur due to mechanical shock, vibration or thermal cycling.

Embedded micropore

Buried micropores will only span between the two inner layers. They do not reach the outside of the board. Many designers will use these types of micropores to span a single layer, which can help simplify the manufacturing process and improve the reliability of through-hole.

Blind hole

Blind wells will start at the surface layer of the plate and then extend one or two layers below the surface before termination. Most designers will have blind wells that cover only one layer. Those who need to span two layers may want to use stacked micropores instead.

Stacked micropores

Stacked vias are "stacks" of buried vias or blind vias stacked on top of buried vias. This is a common way to span multiple layers in a printed circuit board, while helping to improve reliability and reduce the required manufacturing steps. It is important to note that the inner buried micropores in the stack should be filled with conductive adhesive and then plated. This helps provide firm contact for the next through-hole in the stack.

Today, many companies are using these types of through-hole because they need to encapsulate more components in less space. As mentioned earlier, this helps to reduce the size of the board, which means it can be loaded into smaller devices.

However, smaller boards can often save money. The use of micro holes in pads allows connection in pads with various types of surface mount technology. Common through-hole is usually too large for surface mount technology, so this helps ensure a better fit inside the pad without worrying about manufacturing issues. There are many reasons to choose micropores. However, you also need to ensure that they can be manufactured correctly. PCB processing factories explain PCB design and micro hole explanation and analysis. High density interconnection PCBs and micro holes can be placed in smaller spaces.