Innovation in PCB circuit design: understand your prototype selection

Over the years, great changes have taken place in circuit design. Like most industries, innovation and technology have intervened and helped to provide a better way forward. For companies that need to make prototypes of circuit boards, there are several options today. Fortunately, the biggest advantage is that we can now use the prototype of the board, which saves the company thousands of dollars in parts that may not be ready for mass production.

We work with people at every stage of the prototyping and design process to help test all aspects of user functionality and provide people with the solutions they need. Part of this includes educating people about the various design options available and how the prototyping process actually works. This is not a step transaction. The process is divided into several phases, including four different prototypes that the team will use before creating the final product design.

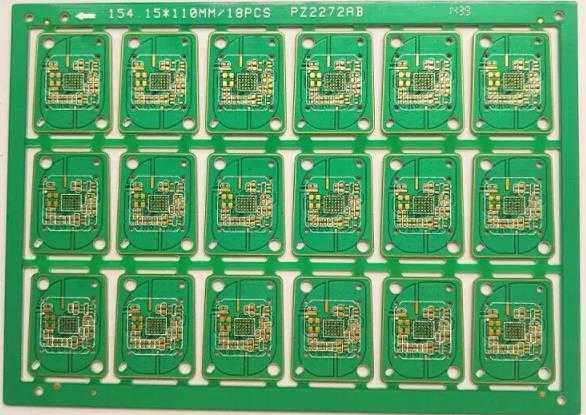

Visual model

This is the first step in prototyping any project. It is just a physical product, and its appearance design is similar to the presented PCB concept. It shows the structure of components and the circuit board itself, which can help engineers find design defects or make visual improvements. For the team, this is the best way to look at PCB boards and see if they are cost-effective and if the design is working properly. This is much easier than trying to visualize things in the brain according to the description on paper.

The visual model ensures that PCB components are assembled together, that the design is effective, and that the dimensions are appropriate for the item under discussion. Before proving that the design is the best choice, it may even make some visual models and determine that the project can continue. It is important that it is done correctly, whether it is a prototype or two prototypes.

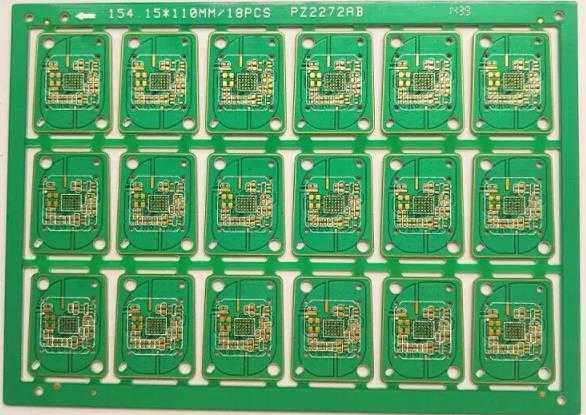

Proof of concept

Proof of concept prototyping is another important step that is often overlooked. This step tests the basic functions of this concept and the concept of PCB as a whole. Essentially, it ensures that the idea itself can work before moving forward and integrating a bunch of components or increasing development costs, without knowing whether the final product will produce the desired results.

This process enables engineers and design teams to test the feasibility of a project by copying the main functions of a PCB. Here they can make the necessary changes and update all aspects of the design so that they can approve the transformation into a working model for testing. Skipping this step and assuming it is feasible may cause serious problems in future prototyping and testing, which is a waste of time and money.

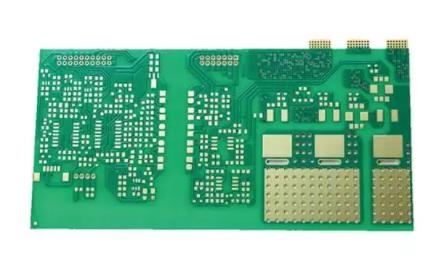

Working prototype

This is the next stage of the process and can only be carried out after the proof of concept is approved. The circuit board will have all the functions of the final design and provide the required tasks, but the component itself may not represent the physical design of the final product. In essence, the prototype is only used for testing to ensure that the PCB board can work properly and all functions can provide ideal results.

The prototypes in work will be adjusted and improved, and once approved, they will be transformed into functional prototypes for final testing. Similarly, the team usually carries out some such designs in the testing process before obtaining feasible results, but this is the importance of this step first. When the product may not be ready, it can save time and money for mass production.

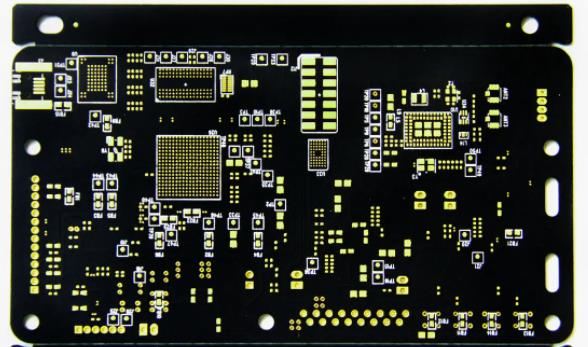

Functional prototype

The final result of any project will be a prototype with complete functions and easy implementation, which will function in all the ways it should, and be as close as possible to the final design of the product. In this way, all contents can be checked finally and PCB operation can be checked before batch production. Designers make them similar to the final product to ensure that everything is normal, visually correct, and has become the first conceptualized idea.

Once the functional prototype is completed and approved, full production can start on a group of PCB boards. This may happen in the first run, which is rare, but it is possible for those who have properly planned and handled the remaining stages. The final prototype usually requires at least two or three attempts to provide ideal results for all investees. The PCB processing factory explained the innovation in PCB circuit design: understand your prototype selection, and the circuit design has undergone significant changes.