What is schematic capture of board design? Now let me tell you

In short, schematic capture is the process of converting paper design into electronic representation that can be handled by software tools such as circuit simulation or PCB design package.

basic principle

A circuit diagram is basically a list of components and a link between these component connections. These can be electronic components, from simple resistors to complex integrated circuit chips or FPGAs, or mechanical components, such as connectors, dials, or switches.

The schematic diagram capture process needs to include all contents in the circuit design required for work, including the electrical connection with its environment. Therefore, attention to details is essential; When things do not work as expected, any omission in the circuit design will lead to a headache, and may lead to high costs of diagnosis and corrective action.

The output of schematic diagram capture process can be imported into other software tools in the form of net list, such as simulation program or PCB design package.

Rule of thumb

When creating a schematic, some tips can save time and prevent problems.

The signal flow should always be from left to right, from input to output. Similarly, the power supply should be from top to bottom. This convention ensures that anyone looking at the schematic will immediately know where the signal comes in and goes out, which lines carry the signal, and which lines carry the power.

All labels should follow a consistent naming convention to help readers understand and highlight potential problems. For example, connections marked as power lines but positioned as signal lines will immediately stand out, saving time for further problem solving during design or manufacturing. PCBA manufacturers will introduce to you that schematic capture is the process of converting paper design into circuit simulation or PCB design package and other software tools.

Wires shall not be crossed or merged when possible to avoid confusion about whether there is connection between wires. Using common symbols for power connections reduces the number of lines and makes the schematic clearer. If you do need a crossing line, please explain to the reader that this is indeed the case. If rows are connected, it is limited to a maximum of three rows. More than three limes meeting at the same time may be mistaken as crossing the boundary.

If the schematic is so large that it covers multiple pages, separate the components so that each page has complete functional blocks, rather than randomly placing them between pages. The connection of line flow between pages should be recognizable.

Don't forget the components that do not belong to functional design: decoupling capacitor, line filter, lightning protection device. A large number of components required for a device to run in the real world are not part of its basic functionality. However, forgetting to include these in the schematic capture will invalidate the simulation results and cause serious problems if they are not included in the PCB layout design.

Finally, if any aspect of the schematic is unclear, add a description. Then, when you get away from thinking about the circuit and do not remember some design decisions made at that time, when you review the schematic diagram, you will thank yourself.

circuit simulation

The simulation tool can be used for schematic design, analog input and monitoring theoretical output. These tools allow designers to test the circuit design under all possible input conditions, verify that the circuit operates as expected, and verify the circuit according to the overall requirements of the equipment it implements.

Each component and input signal included in the schematic diagram needs to define its working parameters and performance characteristics. Although details of standard components are usually available in databases, custom or unusual components may need to define and enter this information. Keep in mind that the simulation will only be as good as the data it uses. Any error, no matter how small, can lead to misleading or unrepresentative results that become apparent only when the assembled equipment is running.

It is important to remember that the simulation tool will tell you what the circuit will do under perfect conditions. Therefore, unless they are added to the model, they will not consider real world influences, such as routing loss caused by impedance or radiated noise. In addition, it will not take into account the interference from the received radiated or conducted noise emission, the crosstalk between signal lines and other indirect effects.

Excellent designers will investigate the sensitivity of their circuit design to these factors, and input these factors into PCB design as constraints. These constraints are converted into minimum width and maximum length parameters of routing, spacing constraints of routing, and shielding/shielding requirements.

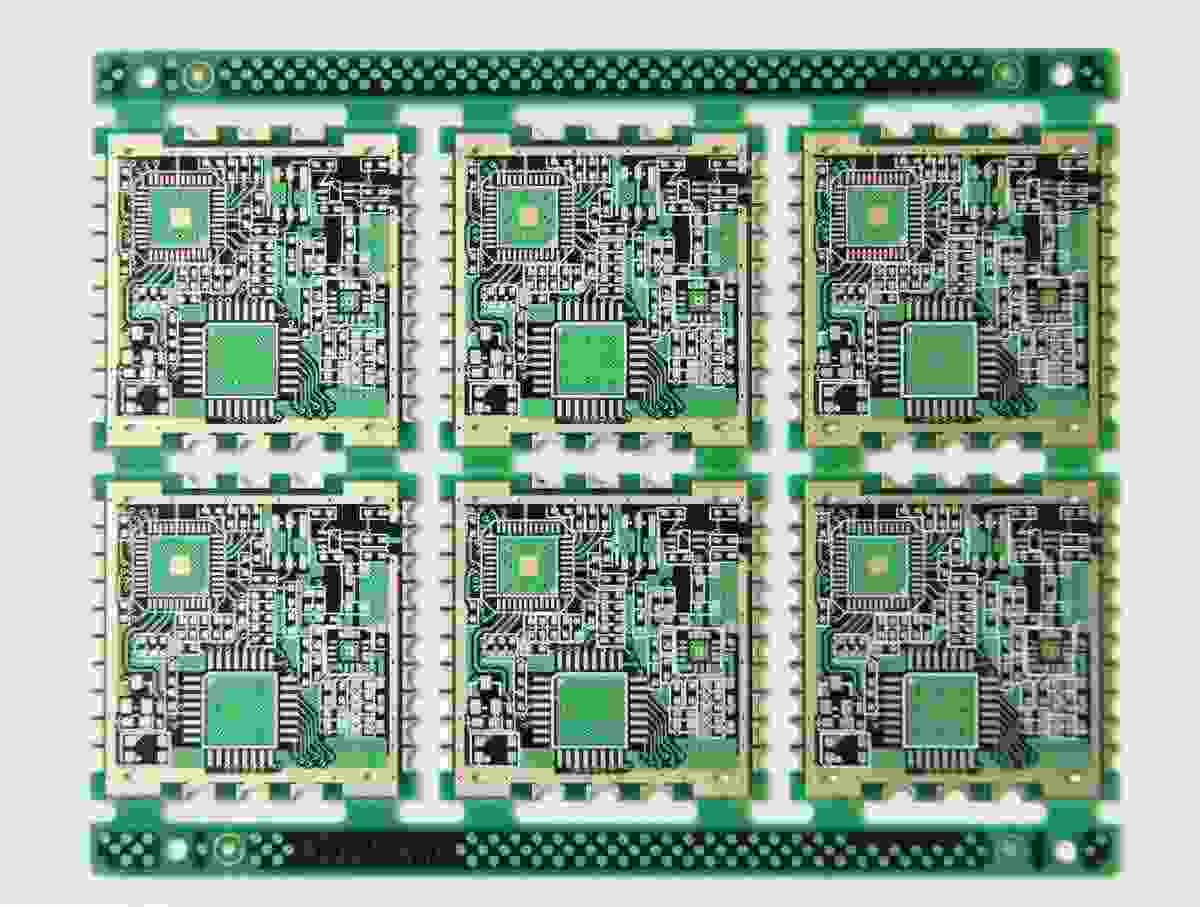

PCB design

Various tools will automatically convert schematic design to PCB layout, optimize part positioning and routing, to maximize performance and meet any specified constraints. However, before committing to manufacturing a circuit board, be sure to carefully check the schematic design. Most software packages contain rule checks that can detect errors, but these are no substitute for manual review.

Simple problems such as the decoupling capacitor is too far away from the component may avoid automatic inspection, which is the reason for keeping alert. If the PCB does not work, any error, no matter how subtle, may lead to a waste of time and money. Solving small problems by drilling holes and adding wiring to bypass traces may be satisfactory for one-time prototyping, but they are not ideal for mass production.

in short

Answer "What is schematic capture?" The problem of. This process allows designers to simulate their circuits to verify their design, and then create the best PCB layout with minimal effort. However, in each step of the process, the designer needs to carefully check to prevent errors from affecting subsequent steps. Simulation tools and PCB design packages can obtain schematic diagrams, making the work of designers easier. However, they are never perfect, and designers should not rely on the output of tools without thorough review.