According to the structure, the stacking mode of the blind holes in the four layer plate can be divided into: asymmetric blind holes, symmetric blind holes, buried holes and HDI. What are the characteristics, advantages and disadvantages of each of these forms?

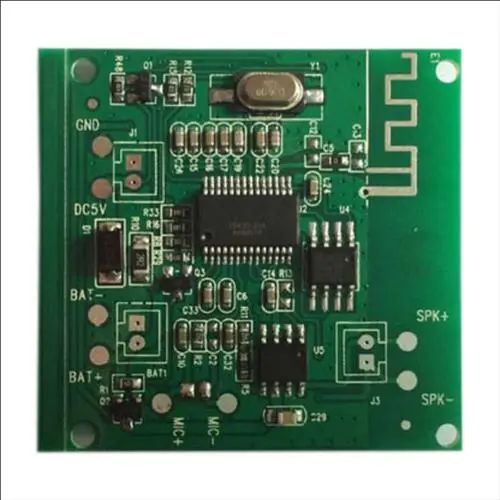

Blind orifice plate

With the continuous reduction of IC technology nodes, the number of I/O pins has increased dramatically. The packaging technology of PCB chips has undergone several generations of changes from DIP, QFP, PGA, BGA, CSP to MCM. The requirements for the graphic technology of PCB motherboards to achieve functions are becoming higher and higher. In order to adapt to high-density, the structure of PCB also develops from through-hole, blind hole to HDI (High density interconnection), ELIC (Every layer interconnection at any layer), The development trend of blind buried orifice plate is good.

The following describes the stacking methods of several four layer blind holes, which can be divided into: asymmetric blind holes, symmetric blind holes, buried holes and HDI according to the structure.

1、 Asymmetric blind hole (I):

Features: blind hole 1 → 2; 1 → 3, through-hole 1 → 4; The minimum hole diameter of mechanical drilling can be 0.15 mm (plate thickness shall not exceed 1.0 mm), which is a feature of blind buried holes.

Advantages: The I/O utilization rate of the first layer is high. The blind hole can be directly drilled on the pad. There is no wiring between the pads. The I/O lead of BGA passes through the inner layer and the bottom layer. The diameter of the pad can be designed to be large.

Disadvantages: the cost of pressing twice is high; The flatness of the board is poor, and the bending and warping of the board are easy to cause difficulties in PCB welding. According to the experience of many circuit board manufacturers, the thickness of the TOP layer is uneven after several times of electroplating, and it is not easy to process fine circuits.

Asymmetric blind hole (II):

Features: blind hole 1 → 2 or 4 → 3, through hole 1 → 4; The minimum hole diameter of mechanical drilling can be 0.15mm (plate thickness shall not exceed 1.0mm).

Advantages: The I/O utilization of the first layer is high. The blind hole can be directly drilled on the pad. There is no PCB routing between the pads. The I/O lead of BGA is from the inner layer. The pad diameter can be designed to be larger.

Disadvantages: The processing cost of two core plates is high.

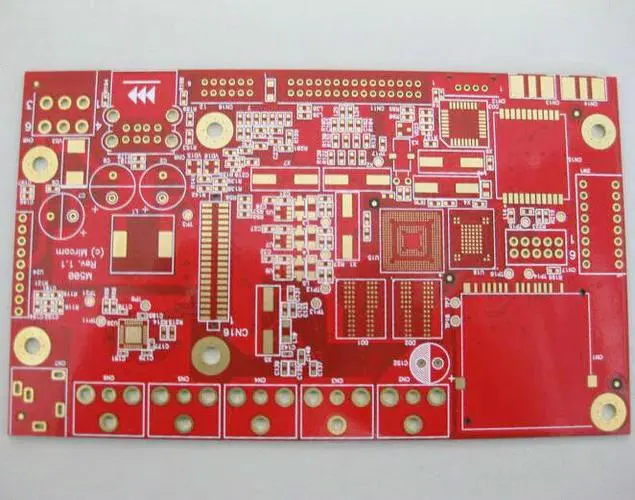

3、 Embedded hole pcb board:

Features: buried hole 2 → 3, through hole 1 → 4; The minimum hole diameter of mechanical drilling can be 0.15mm (plate thickness shall not exceed 1.0mm).

Advantages: The processing cost is low. In the circuit board industry, the blind hole is a special board, and the low processing cost of PCB is a major advantage.

Disadvantages: I/O utilization of layer 1 is not high, and I/O leads of BGA can only be routed between Pads.

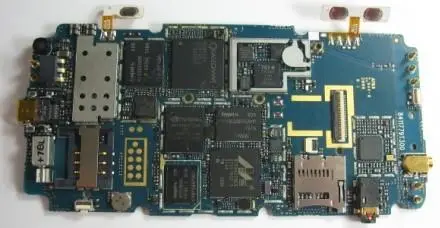

4、 HDI board:

Features: blind hole 1 → 2; 2→3; 4→3; Through hole 1 → 4. 1 → 2 and 4 → 3 must have laser drilling aperture between 0.1-0.15, and the thickness of the medium layer between 1 → 2 and 4 → 3 is less than 0.1mm.

Advantages: The I/O utilization rate of the first layer is high. The blind hole can be directly drilled on the pad, and there is no wiring between the pads. The I/O lead of BGA passes through the inner layer and the bottom layer. The diameter of the pad can be designed to be large, and fine lines can be processed.

Disadvantages: laser drilling is required. The price of samples and small batches is high, while the price of large batches is low. The price of blind holes is relatively reasonable.