The reliability analysis of PCB equipment can be carried out from the following aspects: simplifying the scheme design, using modules and standard components, improving the integration, derating design, selecting high-quality components, reliable structure, mature technology, advanced technology, etc.

Technical measures to ensure the reliability of PCB equipment: scheme selection, circuit design, circuit board design, structural design, component selection, manufacturing process, etc. The specific measures are as follows:

(1) Simplify the scheme design.

During the scheme design, on the premise of ensuring that the equipment meets the PCB technology and performance indicators, the design shall be simplified as much as possible, and the circuit and structure design shall be simplified to make each component the simplest design. Nowadays, the popular modular design method is an effective measure to improve the reliability of equipment. The block function is relatively single, and the system is composed of modules, which can reduce the complexity of PCB design and standardize the design. A lot of facts at home and abroad have proved this point, and the product design should adopt the modular design method.

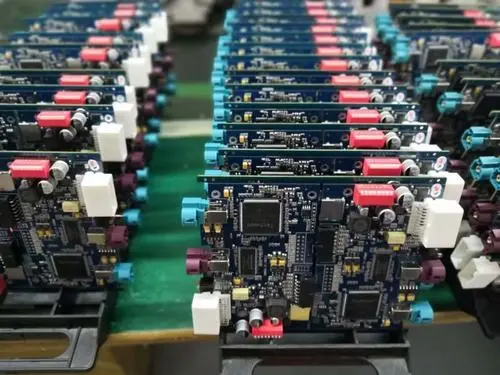

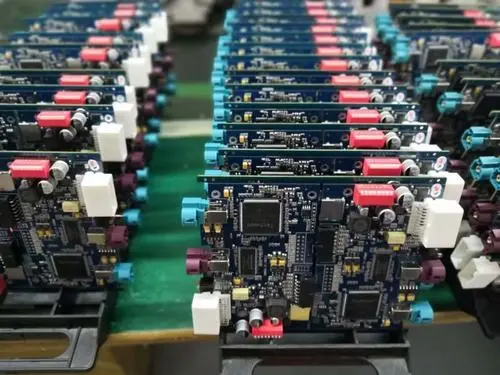

(2) Modules and standard components are used.

Modules and standard components are products that have been proved to be highly reliable after a large number of tests and extensive use, so they can fully eliminate equipment defects and hidden dangers, and also facilitate replacement and repair after problems occur. The adoption of modules and standardized products can not only effectively improve the reliability of the equipment, but also greatly shorten the development cycle, providing extremely favorable conditions for the rapid modification and assembly of the equipment.

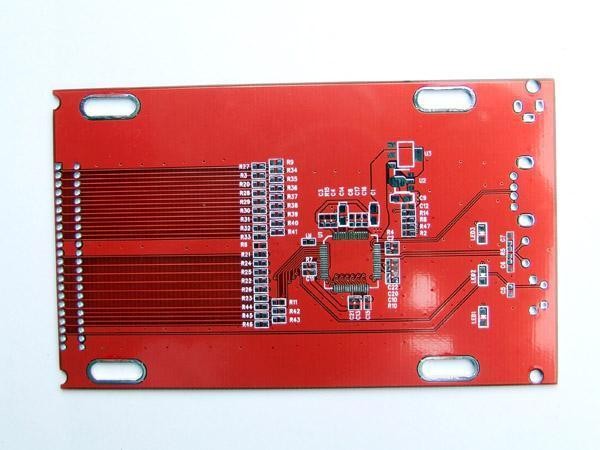

(3) Improve integration.

Select a variety of large-scale and super large-scale integrated PCB circuits with strong functions and high integration to minimize the number of components. The fewer components, the fewer potential hazards. In this way, not only the reliability of the equipment can be improved, but also. It can shorten the research and development cycle.

(4) Derating design.

Derating design means that PCB components work under the condition of lower than their rated stress, which is an effective method to reduce the failure rate of components. Therefore, under the premise of ensuring the technical performance indicators, the design adopts the method of derating for the working voltage range, temperature characteristics, electrical characteristic parameters, etc. of components, so as to reduce the failure rate of components under various stress conditions.

The factors to be considered for derating design are different for different components: some are voltage range, some are current size, some are temperature, some are frequency, some are vibration, etc. In general, withstand voltage, frequency and temperature characteristics of capacitors, power of resistors, current and frequency characteristics of inductors, junction current, junction temperature or fan out coefficient of diodes, triodes, thyristors, operational amplifiers, drivers, gate circuits and other devices, voltage/current and temperature resistance of power switches and main power supply cables, frequency characteristics of signal cables, radiator, connector The use of module power supply and other devices requires derating design.

(5) Select high-quality devices.

Components are the basic components of equipment, and their quality will directly affect the reliability of equipment. Military communication equipment shall be of industrial grade or above as far as possible, preferably military products, and shall be subject to strict aging screening before operation to eliminate early failure components.

(6) Make full use of software resources.

Due to the flexibility of software programming, software resources should be fully utilized in the design. At present, there are relatively many debugging methods and tools for software, which make it easy to locate faults and design problems, and the solution cycle is relatively short. Making full use of software resources is an important method to improve reliability.

(7) Reliable structure, mature and advanced technology.

In circuit and structure design, the number of connectors and metallized holes shall be reduced as much as possible. Circuit components and chips shall be directly welded on the printed board as much as possible. Surface mount devices shall be selected and surface mount technology shall be used to avoid poor contact and ensure the reliability of equipment.

(8) Thermal design.

Excessive temperature is one of the important factors that reduce the performance and reliability of equipment. Therefore, thermal protection measures should be taken to control and reduce the temperature rise of equipment during operation, ensure good heat dissipation and improve the thermal reliability of equipment.

Too low temperature will also reduce the performance and reliability of equipment. Some components cannot work normally when the ambient temperature is too low. Therefore, equipment used in low temperature environment should also be tested at low temperature. The temperature conditions and environment of the equipment must be considered during design.

(9) Electromagnetic compatibility design.

When the equipment is working, it will be interfered by many electromagnetic fields, both natural and man-made. This is especially true for military equipment. In the modern high-tech electronic war against Japan, a very important technical means is to locally emit high-energy electromagnetic waves to destroy the PCB components in the other party's equipment, so as to make the equipment work out of order. Therefore, effective shielding, filtering and other anti-interference measures shall be taken to prevent the interference of noise and interference electromagnetic field on the equipment and ensure the reliable operation of the equipment.

(10) Vibro shock resistant design.

The equipment will be affected by various vibrations and impacts during use and transportation, which will affect its reliability. Therefore, the mechanical strength and stiffness of the equipment should be improved, and vibration damping and buffering measures should be taken to strengthen the equipment's ability to resist vibration and impact and improve the reliability of the equipment.

(11) Fault indicating device shall be adopted.

Fault detection PCB circuit and fault alarm device, so as to find faults in time, thus shortening the equipment troubleshooting time.

(12) It is easy to operate and maintain.

The function of operation and maintenance in the equipment is one of the main factors to ensure the reliability of PCB equipment. In the design, plug-in units and modules shall be used as much as possible, and modular, standardized and quick disassembly structures shall be used to facilitate operation and maintenance. Facts have proved that the modular structure of the equipment can greatly simplify operation and facilitate maintenance.