Explanation of detection circuit in circuit board reverse design system

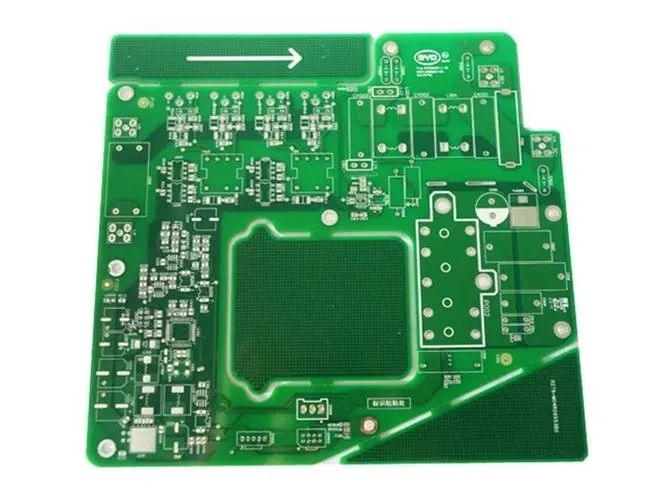

When electronic engineers carry out reverse design or maintenance of electronic equipment, they first need to understand the connection relationship between components on an unknown printed circuit board (PCB), so they need to measure and record the connection relationship between component pins on a PCB.

The simplest way is to turn the multimeter to the "Short Circuit Buzzer" position, use two probes to measure the connection between the pins one by one, and then manually record the on/off state between the "pin pairs". In order to obtain the complete set of connection relationships between all "pin pairs", the tested "pin pairs" must be organized according to the combination principle. When the number of components and pins on the PCB is large, the number of "pin pairs" to be measured will be very large. Obviously, if this work is carried out manually, the workload of measurement, recording and proofreading will be very large. Moreover, the measurement accuracy is low. As we all know, when the resistive impedance between the two probes of a multimeter is as high as about 20 ohms, its buzzer will still make a sound, which is expressed as a path.

In order to improve the measurement efficiency, we must try to realize the automatic measurement, recording and proofreading of the "pin pair" of components. For this reason, the author designed a path detector controlled by a microcontroller as the front-end detection equipment, designed a set of powerful measurement and navigation software for back-end processing, and jointly realized the automatic measurement and recording of path relationships between component pins on PCB. This paper mainly discusses the design idea and technology of path detection circuit to realize automatic measurement.

The premise of realizing automatic measurement is to connect the pin of the tested component into the detection circuit. For this purpose, the detection equipment is equipped with several measuring heads, which are led out through cables. The measuring heads can be connected to various test fixtures to establish connections with the component pins. The number of measuring heads determines the number of pins connected to the detection circuit in the same batch. Under the control of the program, the detector brings the measured "pin pairs" into the measurement path one by one according to the combination principle. In the measurement path, the on/off state between the "pin pairs" is shown as whether there is resistance between the pins. The measurement path converts it into a voltage, so as to judge the on/off relationship between them and record it.

The PCB path detection circuit based on this idea should mainly realize three functions:

·Automatically select the tested "pin pair" and measure;

·Automatically judge the path relationship between "pin pairs";

·The measurement results are recorded automatically.

2 Automatic selection and measurement of tested pin pair

2.1 Automatic switching of tested pin pair

In order to enable the detection circuit to select different pins for measurement from the many measuring heads of connected component pins according to the combination principle, corresponding switch arrays can be set, different switches can be opened/closed by the program, and component pins can be switched into the measurement path to obtain their on/off relationships. Because the measured voltage is an analog voltage, the idea of using analog multiple switches to form a switch array and using analog switch array to switch the measured pin is proposed. PCB assembly and PCB processing manufacturers introduce that electronic engineers are engaged in reverse design of electronic equipment.