Introduction to PCB assembly and PCB processing manufacturers: circuit board design, high speed circuit PCB ground spring explanation

One complete signal circuit, U1 is the driver; U2 is the receiver; L1 and L3 are the package inductances of the UI signal output pin and the ground pin of the component respectively; L2 and L4 are the package inductances of U2 signal output pin and ground pin respectively. Consider a simple case where the reference plane of the signal path is the "ground" of the device UI and U2, and the distance between the signal pin and the ground pin of the component is not close.

According to the basic electromagnetic law, when there is current passing through the circuit, magnetic coils will be generated around the signal path and the return path. The total number of turns of magnetic force lines around one path is composed of magnetic coils generated by the current in the path (self magnetic coils) and magnetic coils generated by other current paths around it (mutual magnetic coils). That is to say, the conductor through which the signal current flows has inductance, and the total inductance is composed of two parts: self inductance and mutual inductance. The current direction of the two paths is opposite, so is the magnetic coil. Therefore, the total inductance of one path is the difference between self inductance and mutual inductance. If the self inductance of the signal path is LA; The self inductance of the return path is LB; The mutual inductance between them is LAB;

If the circuit current changes, an induced voltage will be generated at both ends of all inductors. The voltage generated on the circuit path is the ground bounce, and the ground bounce voltage depends on the speed of current change.

The earth spring is the voltage between two points on the return path, which is generated by the rapidly changing current in the loop. The ground missile has little influence on the drive end, mainly affecting the reception, which is equivalent to the noise superimposed on the received signal. If there are multiple output gates switching states at the same time, the ground bounce noise will increase several times, that is, synchronous switching noise.

There are only two ways to reduce the ground spring voltage:

• Minimize changes in loop current. This means reducing the edge change rate and limiting the number of signal paths sharing the return path;

• Second, minimize the return path inductance. Reducing the inductance of the return path includes two aspects: reducing the self inductance of the return path and increasing the mutual inductance between the signal path and the return path. Reducing self inductance means making the return path as loose as possible; while increasing mutual inductance means making the return path and signal path as close as possible.

Here are some specific measures:

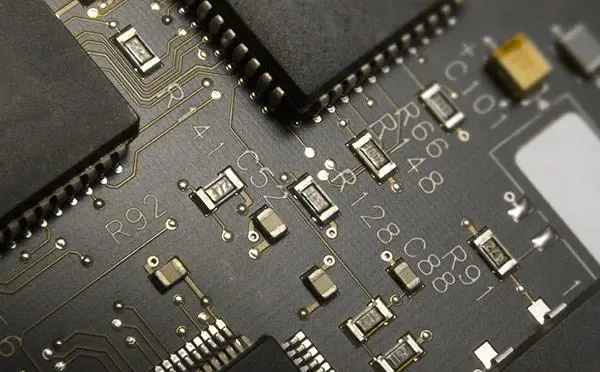

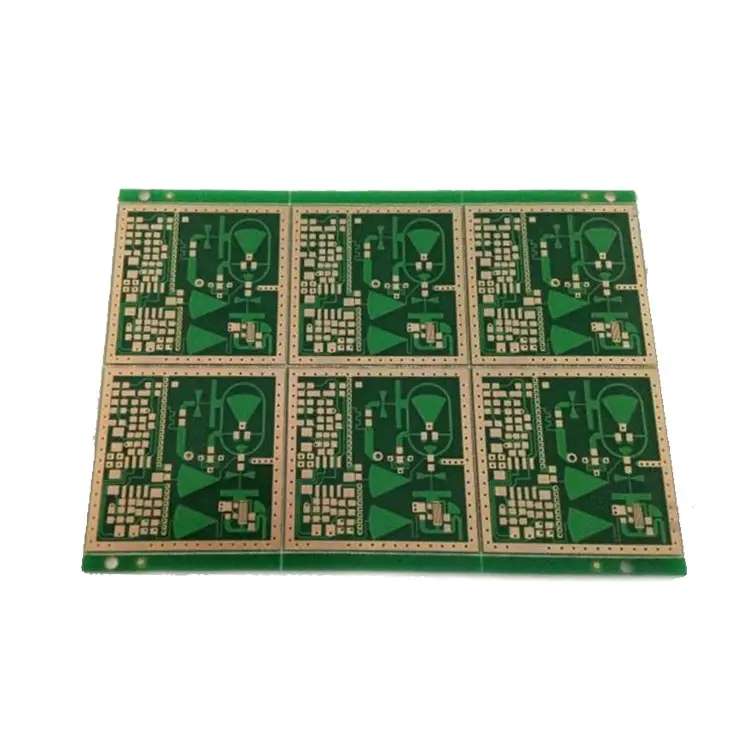

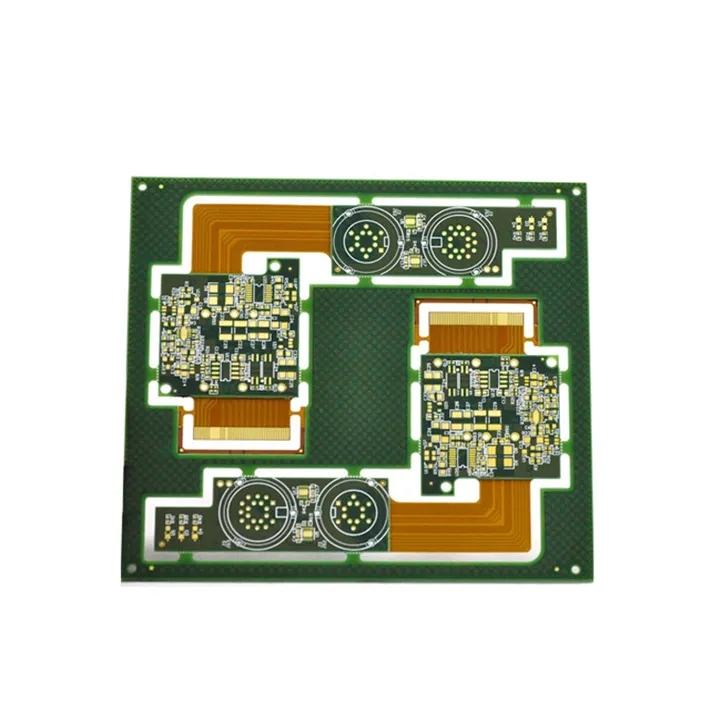

• Layout the power and ground reference planes with multilayer PCB boards, and solder the power and ground pins of components directly on the planes to ensure the lowest inductance and impedance of power or ground pins;

• Try to use components with low switching speed;

• For components, ground pins can be added during packaging, power supply pins can be additionally allocated to the power stage, and a ground reference pin can be allocated to the input circuit;

• Use the scoring input mode;

• Avoid using sockets and winding boards;

• The decoupling capacitor shall be as close to the ground pin of the element as possible.

Ground spring is the noise source generated by logic elements. Due to the faster edge rate of signal and the faster speed of voltage switch, ground spring sometimes becomes a serious problem, which should be paid more attention in design. Introduction to PCB assembly and PCB processing manufacturers: explanation of high-speed circuit PCB in circuit board design.