Everyone makes mistakes, and PCB design engineers are no exception. Contrary to the general public's perception, as long as we can learn from these mistakes, making mistakes is not a bad thing. The following is a brief summary of PCB design

Let's face the reality. Everyone makes mistakes, and PCB design engineers are no exception. Contrary to the general public's perception, as long as we can learn from these mistakes, making mistakes is not a bad thing. The following will briefly summarize some common mistakes in PCB design.

1. Lack of planning

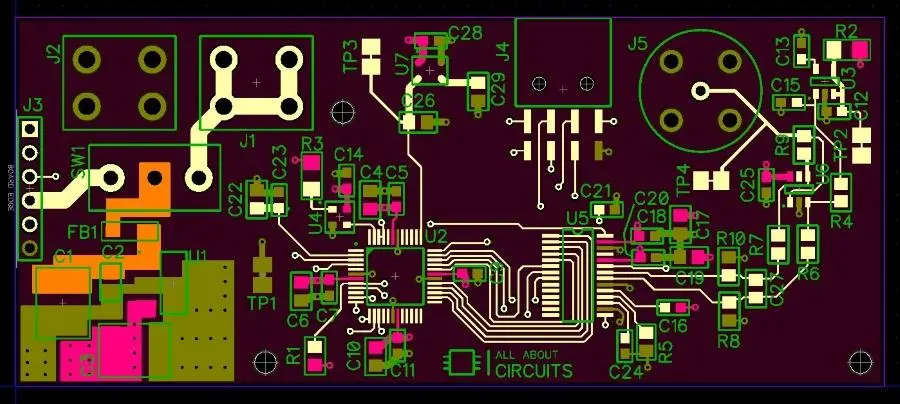

As the saying goes, "If one has no plan in advance, he will find trouble and find it." This also applies to PCB design. One of the many steps for PCB design to succeed is to choose the right tool.

Today's PCB design engineers can find many powerful and easy-to-use electronic design automation (EDA) software suites on the market. Each has its own unique capabilities, advantages and limitations.

In addition, it should also be noted that no PCB software is foolproof, so problems such as component packaging mismatch are bound to occur. It is possible that no single tool can meet all your needs.

Even so, you must study hard in advance to find the best product that best suits your needs. Some information on the Internet can help you get started quickly.

2. Poor communication

Although the practice of outsourcing PCB design to other manufacturers is becoming more and more common and often very cost-effective, this practice may not be suitable for PCB design with high complexity, because performance and reliability are extremely critical in this design.

With the increase of design complexity, in order to ensure accurate component layout and wiring in real time, face-to-face communication between engineers and PCB designers becomes very important. This face-to-face communication will help to eliminate expensive rework in the future.

It is also important to invite PCB manufacturers to join in the early stage of the design process. They can provide initial feedback on your design. They can maximize efficiency according to their processes and procedures, which will help you save considerable time and money in the long run.

By letting them know your design goals and inviting them to participate in the early stage of PCB layout, you can avoid any potential problems and shorten the time to market before the product is put into production.

3. Failure to thoroughly test early prototypes

The prototype board allows you to prove that your design is operating according to the original specifications. Prototype testing allows you to verify the function, quality and performance of PCB before mass production.

Successful prototype testing requires a lot of time and experience, but a strong test plan and a clear set of goals can shorten the evaluation time and reduce the possibility of production related errors.

If any problem is found during the prototype test, it is necessary to conduct a second test on the reconfigured circuit board.

By incorporating high risk factors in the early stages of the design process, you will benefit from multiple iterations of testing, identify any potential problems early, reduce risks, and ensure that the plan can be completed as scheduled.

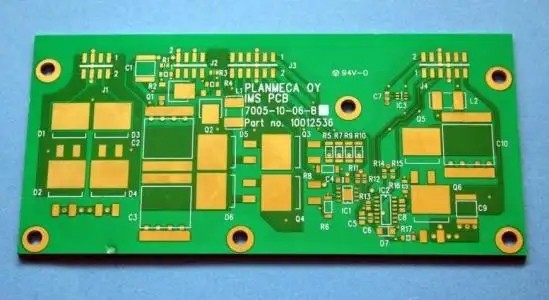

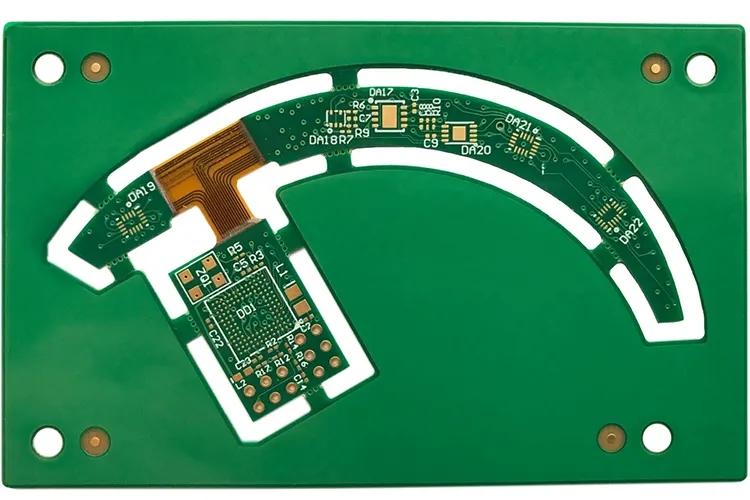

4. Using inefficient layout techniques or incorrect components

Smaller and faster devices allow PCB design engineers to design complex layouts. This design will use smaller components to reduce the occupied area, and they will also be placed closer together.

Using some technologies, such as embedded discrete devices on the internal PCB layer, or ball grid array (BGA) packaging with smaller pin spacing, will help reduce the size of the circuit board, improve performance, and reserve space so that it can be redone after encountering problems.

When used with components with high pin count and smaller spacing, it is important to select the correct PCB layout technology at design time, so as to avoid problems in the future and minimize manufacturing costs.

In addition, you must carefully study the value range and performance characteristics of the alternative components you plan to use, even those marked as drop in replacement PCB components that can be directly inserted. Minor changes in the characteristics of replacement components may be enough to mess up the performance of the entire design.

5. Forget to backup your work

Back up important data. At the very least, you should back up your most important work achievements and other irreplaceable files.

Although most companies will back up all the company's data every day, some smaller companies may not do this, or if you work from home, you will not do this.

Nowadays, it is so convenient and cheap to back up data to the cloud. There is no excuse not to back up the data and store PCB data in a safe place to avoid theft, fire and other local disasters.

6. Become a single island

When I was a programming engineer in my early years, I remember that we spent too much time reviewing code design. But looking back, I have to admit that they are really a very important part of this process, and this importance is the same in PCB design.

Although you may think that your design is perfect, and making mistakes is not your style at all, many times your peers will see some mistakes in your design that you did not notice.