What are the test points in PCB design?

Manufactured printed circuit boards (PCBs) typically go through an automated test cycle. These tests check for component pins that are not connected to the board with the correct solder joints. Test points are placed on the board during the PCB design process to ensure that the integrity of the component assembly process is not compromised. The probe system is used to contact test points added during the PCB design process. This type of testing typically uses several different techniques:

Online Test (ICT)

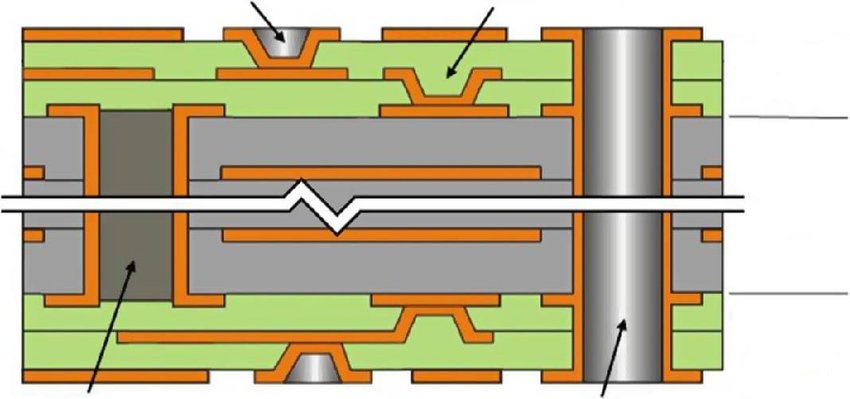

In-Circuit Test is a system designed to test all nets on a PCB simultaneously. To test all the nets at once, In-Circuit Test (ICT) employs a test fixture whose probe positions are relative to the positions of all test points on the board and will touch each test point on the board simultaneously. The fixture will have a probe for each test point whose position is relative to the position of each test point on the PCB. This allows testing to be completed very quickly. These fixtures are usually used to test the bottom of the board, but can also be set up to test the top or both sides of the board at the same time, but at a higher cost.

flying needle

As you might guess from the name, these probes "fly" across the board, touching each specific test point in the order in which they were programmed to test. Flying probe differs from in-circuit testing in that it uses only two to six probes to check all test points on the board. Due to the more specific test types, flying probes require more time to test the same board that passes ICT. Unlike ICT, flying probe testing cannot perform any functional testing of the board because there are not enough probes available for each test point.

Other available tests:

Manufacturing Defect Analyzer, MDA

This type of test uses basic in-circuit tests for resistance, continuity, and insulation. As the name suggests, MDA is only used to identify manufacturing defects such as shorts across traces and open trace connections.

Cable Form Tester

This type of test fixture is used to test cables. It uses the same basic functionality as an MDA, but often some form of high voltage may be required to test insulation optimization. The operation of the cable form tester is optimized for cable testing.

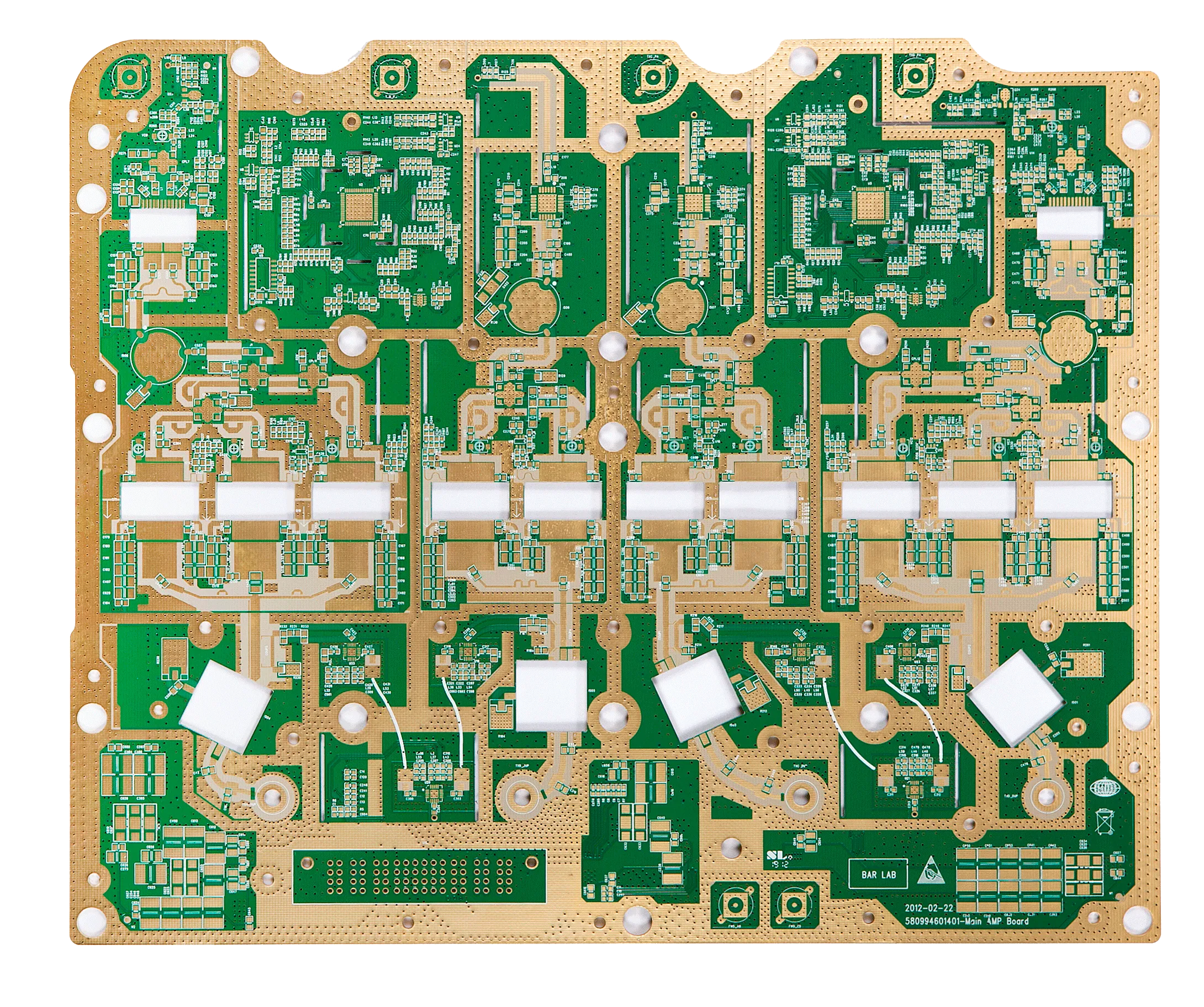

Screen shot of PCB with test points

These test methods appear in PCB design and PCB manufacturing.