Discuss the principle and difference between aluminum substrate and glass fiber board

First, what is fiberglass printed circuit board

The alias of glass fiber board: glass fiber heat insulation board, glass fiber board (FR-4.), glass fiber composite board, which is composed of glass fiber materials and high heat resistant composite materials, and does not contain asbestos harmful to human health It has high mechanical and dielectric efficiency, good heat resistance and moisture resistance, and good processing efficiency Used in plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCBs ICT fixtures, and table polishing pads

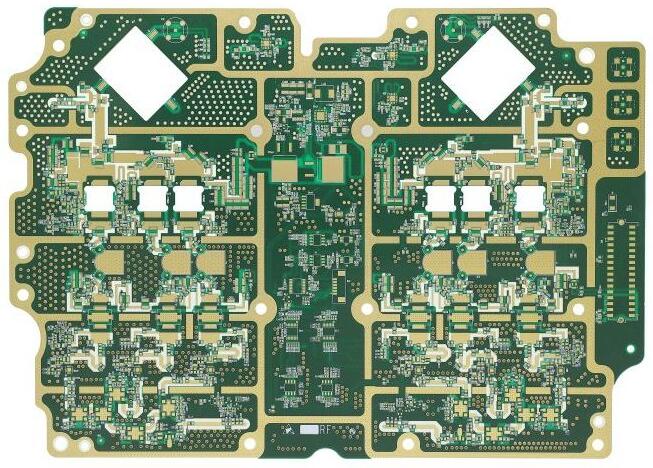

PCB board

1. Advantages of fiberglass board

(1) It has high mechanical efficiency and resistance, good heat resistance and moisture resistance, and good processing efficiency. It is generally used in plastic mould and machinery manufacturing.

(2) Injection mold molding usually requires: high temperature materials and low temperature mold The heat insulation method must be used under the same machine conditions Keep the injection mold at a low temperature, and do not make the injection molding machine too hot This requirement can be met by installing insulating plates between the injection mold and the injection molding machine Shorten production cycle, improve productivity, reduce energy consumption and improve the quality of finished products The continuous production process ensures stable product quality, prevents the machine from overheating, no power failure, and no oil leakage in the hydraulic system

2. Use of glass fiber board

(1) Construction industry: it can be used for cooling towers, building structures, indoor equipment and decorative parts, glass fiber reinforced plastic panels, decorative panels, solar energy utilization devices, etc.

(2) Chemical industry: it can be used for anti-corrosion pipe, anti-corrosion pump and its accessories, grille, ventilation facilities, waste water and sewage treatment equipment, etc.

(3) Automobile and railway transportation industry: it can be used as auto shell and other parts, as well as shell, door, inner panel and instrument panel of large passenger cars; In highway construction, there are road signs, isolation piers and highways. Guardrail, etc.

(4) The efficiency of glass fiber board, glass fiber board, can generally be used for flexible packaging base, and then covered with cloth, leather, etc., can be made into beautiful walls and ceilings decoration.

(5) It has the advantages of sound insulation, environmental protection, and flame retardant It has been used in radar shell due to its good insulating property and is also a good anti-corrosion material Now it has been widely used in the chemical industry Glass fiber board has the advantage of strong plasticity

Second, what is the aluminum substrate

Aluminum substrate is a metal base copper clad plate with good heat dissipation function. Generally, a single panel is composed of three layers, namely circuit layer (copper foil), insulation layer and metal base layer. For high-end applications, it is also designed as a double-sided board, with the structure of circuit layer, insulation layer, aluminum base, insulation layer and circuit layer. Few applications are multilayer boards, which can be made by bonding ordinary multilayer boards with insulating layers and aluminum bases.

1. Advantages of aluminum substrate

(1) The heat dissipation is obviously superior to the standard FR-4 structure.

(2) The thermal conductivity of the dielectric used is usually 5 to 10 times that of traditional epoxy glass, and the thickness is only one tenth.

(3) The heat transfer index is more effective than the traditional rigid PCB.

(4) It is possible to use a lower copper weight than shown in the IPC recommendation chart.

2. Use of aluminum substrate

(1) Audio equipment: input and output amplifiers, balance amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

(2) Power supply equipment: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

(3) Communication electronic equipment: high-frequency amplifier, filtering device and transmission circuit.

(4) Office automation equipment: motor drive, etc.

(5) Automobile: electronic regulator, igniter, power controller, etc.

(6) Computer: CPU board, floppy disk drive, power supply device, etc.

(7) Power module: inverter, solid state relay, rectifier bridge, etc.

Aluminum substrate has a wide range of applications Generally, audio and communication equipment includes aluminum substrate, power supply equipment, communication electronic equipment, office automation equipment, automobile, computer, and power module

3. Aluminum substrate design

The main scientific and technological requirements are as follows:

Dimensional requirements, including circuit board size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delaminations, aluminum oxide film, etc; Efficiency, including peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance requirements

Special testing methods for aluminum-based copper clad laminates:

The first is the measurement method of dielectric constant and dielectric loss factor, which connects the sample and the tuning capacitor to a high frequency circuit in series to measure the Q value of the series circuit;

The second is the thermal resistance measurement method, calculated according to the ratio of temperature difference and heat conduction between different temperature measurement points

4. Aluminum substrate circuit production

(1) Mechanical processing: Drilling of aluminum sample is possible, but burr is not allowed on the hole edge after drilling, which will affect the withstand voltage test Milling shapes is very difficult The punching shape requires the use of advanced molds, and the mold making is very skilled, which is one of the difficulties of aluminum substrate After the contour is punched, the edges shall be very neat without any burrs, and the solder mask at the edge of the circuit board shall not be damaged Normally, using military exercises, this hole is punched from the circuit, and the shape is punched from the aluminum surface to punch the circuit board with upward shear force and downward force These are skills After stamping, the warpage of the plate shall be less than 0.5%

(2) The whole production process is not allowed to rub the aluminum base surface: the aluminum base surface will be discolored and blackened when touched by hand or through certain chemicals. This is absolutely unacceptable The customer can use the re polished aluminum base surface This is unacceptable. In retrospect, one of the difficulties in aluminum substrate production is that the entire process does not scratch or contact the aluminum base surface Some companies use passivation technology, and some put a protective film before and after the hot air level (scattering tin) have many tricks

(3) High voltage test: 100% high voltage test is required for the aluminum substrate of communication power supply. Some customers need DC power, some need AC power, the voltage needs 1500V, 1600V, the time is 5s, 10s, 100% PCB test Dirt, holes, burrs, linear serrations on the edge of aluminum base, and scratches on any point of the insulation layer on the board will cause fire, leakage, and breakdown in high-voltage test The pressure test plate was rejected due to delamination and blistering

5. Specification for aluminum substrate PCB production

(1) Aluminum substrates are frequently used in power devices, with high power density, so the copper foil is relatively thick If more than 3oz copper foil is used, the etching process of thick copper foil requires engineering design line width compensation, otherwise, the line width after etching will exceed the tolerance

(2) The aluminum base surface of the aluminum substrate must be protected with a protective film in advance during PCB processing In addition, the protective film is easy to scratch and cause gaps, which requires that the entire PCB processing process must be inserted into the rack

(3) The hardness of the milling cutter used for glass fiber boards gongs is relatively small In the process of processing, the milling cutter used to produce fiberglass board is fast, while the production of aluminum substrate is at least two-thirds slow

(4) The computer milled fiberglass board can only use the heat dispersion system of the machine itself to disperse heat, but for the processing of aluminum substrate, additional alcohol must be added in the gong to dissipate heat

3, the three major differences between glass fiber board and aluminum substrate

1. In terms of price

Compared with the price of fiberglass board and aluminum substitute, the price of fiberglass board is much cheaper

2. Process

According to the different materials and production processes, glass fiber board can be divided into three types: double-sided copper foil glass fiber board, perforated copper foil glass fiber board and single-sided copper foil glass fiber board Of course, the price of fiberglass board made of different materials will also be different

3. Performance

Because the aluminum substrate has good thermal conductivity

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.