Causes of Poor PCB Coating

1 pin hole PCB circuit board Pinholes are caused by hydrogen adsorption on the surface of electroplated parts and delayed release The plating solution shall not wet the surface of the plated parts, so that the coating cannot be electrodeposited With the increase of coating thickness near the hydrogen evolution point, pinholes formed at the hydrogen evolution point It is characterized by a shiny round hole and sometimes an upward small tail When there is no wetting agent in the bath and the current density is high, pinholes are easily formed

2. Pits. Pitting is caused by dirty electroplating surface, adsorption of solid substances or suspension of solid substances in the electroplating solution. When they reach the workpiece surface under the action of electric field, they will be adsorbed on the workpiece surface and affect the electrodeposition. These solid substances are embedded in the electroplating coating of PCB multilayer board to form small bumps (pits). They have the characteristics of convexity, no brightness and no fixed shape. In short, they are caused by dirty workpieces and dirty plating solution.

3. Air streaks. Due to too much additives, too high cathodic current density or too high complexing agent, the gas flow strip will reduce the cathodic current efficiency, resulting in a large amount of hydrogen evolution. If the bath flows slowly and the cathode moves slowly at this time, the arrangement of electrodeposited crystals will be affected during the process of hydrogen rising to the surface of the workpiece, thus forming a bottom-up airflow stripe.

4. Masking (bottom exposed). The shielding is because the soft spill on the pin on the workpiece surface has not been removed, and the electrodeposition coating cannot be carried out here. The PCB multilayer board can see the base plate after electroplating, which is called bottom exposure (because the soft spill is translucent or transparent resin).

5. The coating is fragile. After the smdpcb multilayer board is electroformed, cracks can be seen at the bending of the pin. When the nickel layer between the nickel layer and the matrix cracks, it is determined that the nickel layer is brittle. When there is a crack between the tin layer and the nickel layer, the tin layer is determined to be brittle. Brittleness is mainly caused by excessive additives and brighteners, or excessive inorganic and organic impurities in the plating solution.

6. Air bag. The formation of air bag is determined by the workpiece shape and gas accumulation conditions. Hydrogen accumulates in the "bag" and cannot be discharged to the level of electroplating solution. The presence of hydrogen blocks the electrodeposition of the coating. Make the parts with hydrogen accumulation uncoated. When electroplating PCB multilayer boards, pay attention to the hook direction of the workpiece to avoid cavitation. As shown in the figure, when the work-piece PCB multilayer board is electroplated, when it is hooked perpendicular to the bottom of the electroplating tank, no air bag will occur. When the hook is parallel to the bottom of the groove, it is easy to generate air bags.

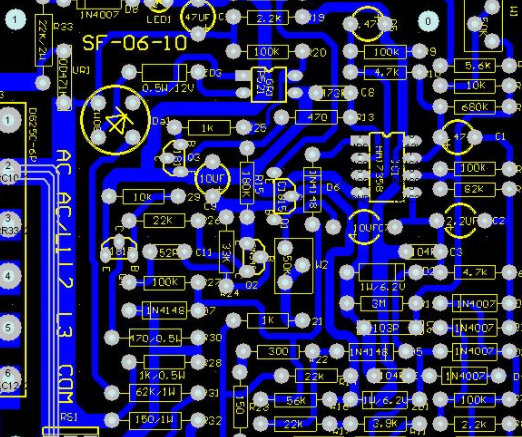

Printed circuit board

7. Open a "tin flower" in the center of the black body of the plastic seal. The black body has a tin coating. This is because when the electron tube is in the weld, the upward parabola of the gold wire is too high. In the process of plastic packaging, the gold wire is exposed on the black body surface, and tin is plated on the gold wire like flowers. This is not an electroplating solution problem.

8. "Climbing Tin". At the junction (root) between lead and blackbody, there is a layer of tin, which crawls onto the blackbody like wall grass. The tin layer is a dendritic loose coating. This is because in the pre plating process, the SMD frame uses a copper brush, and the worn copper powder embedded in the black body is not easy to be washed away, becoming a conductive "bridge". When electroplating PCB multilayer boards, as long as the electrodeposited metal is placed on the "bridge", the dendritic deposits will crawl to connect with other copper powders, and the area of crawling tin will become larger and larger.

9. "Whisker tin" is located at the junction of lead and blackbody, with whisker tin on both sides of lead, and tin coke shaped tin stack at the junction of lead front and blackbody. This is because when the SMD frame is silver plated by the masking method, the masking device is not tight, and silver is also plated where silver is not required. During the plastic packaging process, some silver layers are exposed outside the blackbody. In the pretreatment process, the silver layer is pried up, and the tin plated on the silver is in the form of whiskers or tin stacks. Overcoming the exposure of silver layer is one of the keys of silver mask electroplating technology.

10. Orange peel coating. When the substrate is very rough, or corrosion occurs during pretreatment, or ni42fe+Cu substrate is treated before electroplating, some copper layers have been removed, but the copper layers in some areas have not been removed, and the entire surface is not smooth. The above conditions may cause the coating to appear orange peel.

11. Cavity plating. The coating surface has irregular pits (different from pinholes), which is a "ceiling surface" coating. There are two situations where a "ceiling surface" coating can be formed.

(1) Some devices use glass bead spray to remove spills. When the spraying pressure is too high, the kinetic energy inertia of the glass bead will impact the electroplating surface into small pits. When the coating is too thin and the pits are not filled, it will become a "ceiling panel" coating.

(2) The metallography of the base alloy is uneven, and there is selective corrosion during the pre plating process. (The highly active metal is first etched to form pits). After PCB multilayer board electroplating, the "ceiling board surface" coating is formed when the pits are not filled.

For example, for ni42fe based data, if nickel and iron are not fully mixed evenly in the metallurgical process, there may be uneven alloy metallography in some areas of the rolled data surface. During the pre plating process, since iron is more active than nickel, selective etching is preferred to form pits. If the electroplating layer of PCB multilayer board cannot be flat, it will become the coating of "ceiling board surface". Similarly, zinc brass has the same phenomenon. If the copper zinc metallography is uneven, during the pre plating process, zinc is selectively corroded before copper. This substrate is concave, and the PCB multilayer plate is concave after electroplating.

12. The dendritic coating is loose. When the bath is dirty, the concentration of main metal ions is high, the complexing agent is low, the additives are low, the anode and cathode are too close, the current density is too high, and loose dendritic coatings are easy to form in the current area. The loose coating is like foam plastic, and the branches are uneven.

13. Double coating. The formation of double layer coating mainly occurs when the working temperature of the plating solution is relatively high. In the electroplating process of PCB multilayer board, take the workpiece out of the electroplating tank and hang it again. In this process, if the workpiece is raised for a long time, the electroplating solution on the workpiece surface will deposit salt frost due to water evaporation and adhere to the workpiece. When the salt frost is not dissolved in time, the coating is plated on the salt frost surface to form a double-layer coating, such as Huafu biscuits. There is a layer of salt frost between the two coatings.

In order to avoid double coating, the workpiece can be shaken in the electroplating solution for a few seconds before continuous electroplating, and then energized for continuous electroplating after the salt frost is dissolved.

14. The coating is blackened. The main reasons for the blackening of the coating are the high metal and organic impurities in the bath, especially in the low current density area; In the case of insufficient additives, black coating will also appear in the middle of large-area electroplating; If the temperature is too low and the ionic activity is low, a gray black coating will be formed when the current is too high. In order to deal with metal impurities, corrugated plates can be used as the cathode of electrolysis at 01-0.2a/dm2. Organic pollution can be treated with 3-5 g/L activated carbon. Rinse with granular water first.

15. Blunt peeling. Ni42fe alloy is easy to be passivated. Activation before electroplating includes two chemical processes, one is oxidation process, the other is oxide dissolution process. If the oxidation process is not sufficient or the oxide is not dissolved in time, the electroplating surface will still have oxide residues, and the coating will peel off or be rough.

16. Replace the peel. If there are two different data on the same workpiece. For example, the copper substrate surface is nickel plated, and the copper is exposed to the notch after cutting and forming. When the copper ion in the strong etching bath increases to the limit value, the replacement copper layer is easy to be generated on the nickel layer. After replacing the copper, the tin layer will peel off after tinning. In this case, the strong corrosion solution can only be renewed frequently to avoid peeling.

17. The oil stain peels off. If the oil is not removed during the pre plating process, there is no coating on the oil contaminated area of the PCB multilayer board during the electroplating process. Even if the coating is covered, it is also a false coating. The coating has no binding force with the substrate, and the substrate is raised one by one like a rubella, which will fall off when wiped.

18. Dark dot coating. When the workpiece has a large electroplating area, such as the radiator of the pipe. When there are many impurities or insufficient additives in the plating solution, a dark gray dot coating, such as gypsum, will form in the center of the radiator. Since the center of the large area is a low current area, impurities are concentrated here. Or when the additive is insufficient, the depth ability of the plating solution decreases.

19. The coating has uneven luster and obvious (visual) uneven thickness. This is because the additive has just been added, and the additive is not completely dispersed, resulting in inconsistent bath characteristics. After the additives are uniformly dispersed, the fault will disappear naturally.

20. The plating solution is polluted by chemical fibers, and it can be seen that there are trace chemical fibers embedded in the coating. Using iron ironing method to make PP fabric of anode bag can overcome this defect.

21. Mold pollution in electroplating solution (mainly in nickel plating bath, because ph4-5 environment is suitable for mold growth). It can be seen that many molds are embedded in the electroplating layer of PCB multilayer board. In this case, disinfection and sterilization measures should be taken. In order to avoid mold contamination, attention must be paid to the implementation of the cylinder opening program of the production line.

Moss pollutes water. The work piece is washed in the water containing moss plants. The moss plants adhere to the work piece and firmly adhere to the work piece after drying, which affects the product quality. Every spring, we should pay attention to the possibility of moss pollution and establish a sense of prevention. If moss contaminates the bath, moss will be embedded in the coating.

23. The coating has high porosity. The high porosity of the coating affects the appearance of the coating, the protective characteristics of the coating, shortens the storage period, affects the weldability, and the brittleness of the coating is greater. Most of the reasons are that the bath is dirty, and there are many metal impurities and organic impurities. The method to identify the coating porosity is to directly identify the characteristics of the plating solution. Hang the polished degreased stainless steel plate on the PCB multilayer board for electroplating for about 0.5-1 hours. If the coating completely wraps the stainless steel plate and the coating can be scraped off the edge with a knife, the entire coating can be torn off with good toughness to form a complete coated plate. Align the coated plate vertically to the sunlight. If no pores can be seen, the characteristics of the plating solution are very good. If you can see transparent electricity (holes) bit by bit, it means that the characteristics of the plating solution are very poor. If you can't tear off the coating from the stainless steel plate and the coating inclines upward like a fish scale, it indicates that the characteristics of the plating solution are very poor and a lot of treatment is required for the plating solution.

24. The coating thickness on the same hanger varies regularly. This is because the projection of the Yin and Yang patterns is not accurate (the relative positions of the anode and cathode are inappropriate), and the power lines are unevenly distributed. The coating thickness on the same hanger varies regularly. This is because the elastic contact resistance of the hook where each workpiece is located is different. The coating thickness of the contact is good, and vice versa. This is the quality of the hanger. If there are two hangers in the same slot, one is thicker and the other is thinner, this is because the aging degree of the two hangers is different. The newer hanger has lower contact resistance and thicker coating, and vice versa. If the projection of anode and cathode is correct, the aging degree of the two hangers is the same, but the coating thickness is thicker on one side and thinner on the other side, and changes regularly. This is due to the corrosion or salt frost on one side of the cathode, resulting in poor electrical contact. In order to make both sides of the plating solution conduct well and eliminate the defect of large voltage drop when one side is energized, if the length of the plating solution is greater than 1m, both ends need to be energized and cleaned regularly to maintain good electrical contact.

25. There are black spots on the surface of some PCB workpieces. There may be two reasons:

(1) The hanger shell is aged and cracked, and the acid, alkali and salt seeping from the crack are sprayed by compressed gas and splashed on the workpiece, polluting the coating.

(2) The water level of flushing water is too low, and the upper workpiece of the hanger cannot be flushed. The workpieces that cannot be cleaned are cross contaminated with the change gear. Recall that the flushing liquid level must be higher than the workpiece on the top of the hanger.

(3) Droplet cross contamination.

(4) There is oil in the gas.

(5) Manual unloading operation contamination.

26. There are two possible cases of workpiece discoloration (yellowing) after electroplating and drying or after short storage:

(1) The concentration of neutralization solution is too low and the temperature is too low to remove the membrane.

(2) The crystal of the coating is rough, which increases the difficulty of washing and removing the film.

27. There are tin nodules on the coating surface. This is because the anode mud polluted the plating solution and the PP bag was broken. When anodic dissolution occurs, on the one hand, it is transferred to the bath in the form of ions, and some of them are flushed into the bath in the form of atoms and atomic clusters, polluting the bath. When the atomic clusters contact the workpiece, they are embedded in the coating to form tin nodules.

28. Blackbody color difference PCB circuit board That is, the black plastic body turns gray black This is because the frame stays in alkaline solution for a long time in the pretreatment or neutralization tank for PCB multilayer electroplating, and the black body has been corroded by alkali The black body consists of epoxy resin, leveling agent, curing agent, anti-aging agent, white filler, melanin, etc When the black body is corroded by alkali, it will show the filler White+black is a gray (heterochromatic) phenomenon.