1.PCB production technology has also changed a lot, and the product has higher and higher requirements on the process. For example, some of the circuit boards in mobile phones and computers are used in gold and copper, which also makes the advantages and disadvantages of the circuit boards become more obvious.

Global Wei technology takes you to explore the surface process of PCB board, compare the advantages and disadvantages of various PCB board surface treatment process and applicable scenarios.

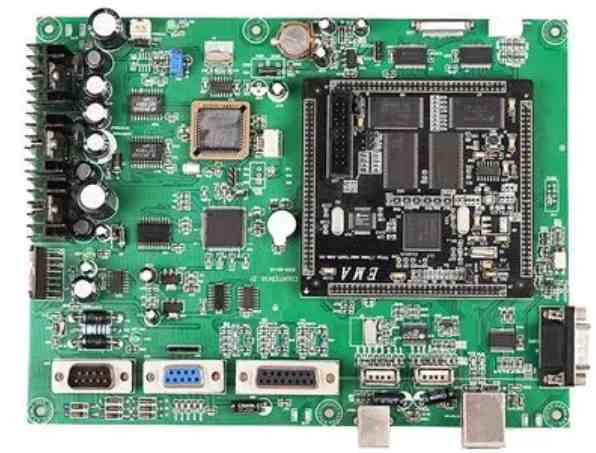

From the pcb patch processing board appearance, its appearance is mainly there are three colors gold - silver - light red. Gold is the most expensive category, silver is next, and light red is the cheapest. From the appearance, it is easy to see whether the manufacturer has cut corners. Several parts of the circuit board are mainly pure copper, referred to as bare copper.

1. Bare copper plate: its advantages are relatively low cost, smooth appearance, and good weldability in the absence of oxidation. But be careful not to be affected by acid and temperature, put a long time copper is easy to oxidize in the air.

2. Gold plate: The gold on the top is gold, even if only a thin coating of this already accounts for 10% of the cost of the entire board. After gold deposition, it is not easy to oxidize, storage time is longer, the surface is relatively flat, suitable for some welding fine gap pins and some small solder joints, such as mobile phone plate, its cost is relatively high, welding strength is relatively poor.

3. Spray tin circuit board: it is silver, it is in the outside of the copper line spray a layer of tin, it can help welding, but there is no way to as gold can long-term contact reliability, long-term use is easy to oxidation rust, resulting in bad contact. Used in some small digital products on the circuit board, its price is cheap.

4. OSP process plate is also called organic welding aid film in SMT factory. Because it's organic, not metal, it's cheaper than the tin-spraying process.

It has all the advantages of bare copper plate welding, even expired circuit boards can be done again surface treatment, is very susceptible to acid and humidity. If it's too old for more than three months, it has to be resurfaced. OSP is the insulating layer, so the test point needs to be printed with solder paste to remove the original OSP layer before it can contact the pin point for electrical testing.

kingford focuses on one-stop production and manufacturing services such as SMT patch processing, DIP plug-in post welding, PCBA burning test, PCB circuit board manufacturing, electronic component purchasing, OEM OEM.

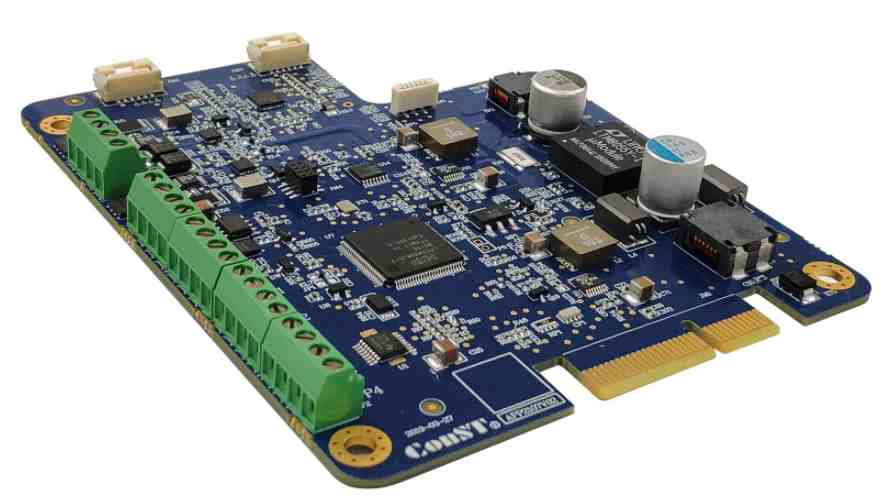

2. Reliability of SMT patch processing and assembly process

With the wide application of electronic products, the reliability of electronic products has become a prominent problem. Most applications require electronic products to operate stably, reliably and safely. In aviation, aerospace, military, communications, finance, surveillance and other fields, the failure and failure of electronic systems may cause huge losses.

The reliability of electronic products and systems is particularly complicated because electronic products consist of complex types and different materials, such as electronic components, PCB circuit boards, solder, auxiliary materials and software. From the manufacturing perspective of electronic products, electronic manufacturing can be divided into four levels, namely level 0 (semiconductor manufacturing), level 1 (PCB design and manufacturing, IC packaging, passive device manufacturing, process materials and other electromechanical components manufacturing), level 2 (board level assembly of electronic products), level 3 (complete assembly of electronic products). Corresponding to 4 layers of classification, the reliability of electronic products can also be divided into 4 aspects, corresponding to the whole machine is the system level reliability of electronic products, corresponding to the board level is the board level process reliability, that is, the surface assembly process reliability, corresponding to packaging, components and process materials is the reliability of components, the corresponding semiconductor manufacturing is the reliability of the semiconductor process.

The Design For Reliability of electronic assembly process includes three aspects: simulation design, failure analysis and reliability test. The business development and staffing of the process reliability department of the industry leading large electronics companies are basically carried out according to this framework. The three aspects of the work can complete the assembly process reliability from qualitative analysis to quantitative design requirements. However, for most small and medium-sized electronics companies, it is difficult to build such a large system and organize a complete reliability department and design process. It would be more effective for them to develop their own electronic assembly process reliability specifications or guidelines to guide how to take action to meet reliability requirements during the PCB design phase, PCBA assembly process, process failure analysis and process reliability testing, and as new processes emerge.