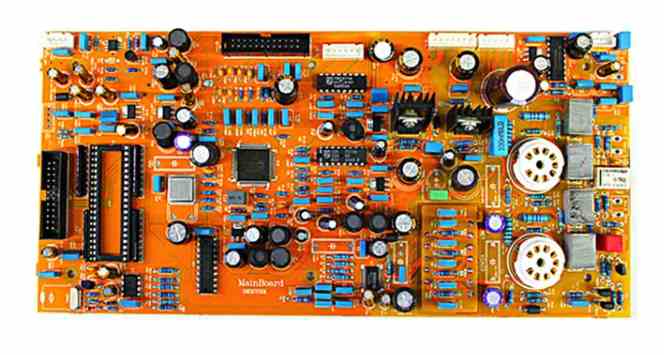

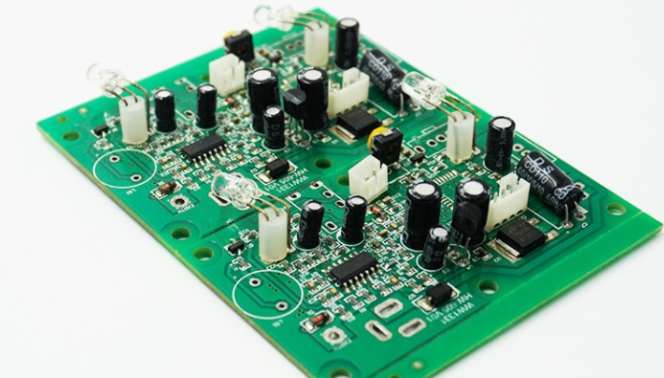

Although smt patch processing is now automated, it does not mean that manual work is completely unnecessary. In fact, in the smt patch processing and maintenance process, manual operation is inevitable. Therefore, as an operator, we must master the skills of manual maintenance. So, smt patch processing and maintenance, manual maintenance skills are what? The following patch manufacturer will tell you what smt patch processing and maintenance skills and what are the relevant knowledge of patch welding skills.

1. What are the welding skills of the patch

Want to improve the SMT patch welding efficiency? No problem, as long as you master the patch welding techniques provided in this article, you will definitely improve the effect. So, what are the tips for patch welding? The following Xiaobian will be shared for everyone.

First, clean up the iron head

This is a very key step. Cleaning up the iron head will be of great help to the next step, especially when the tin is on the pad. Cleaning up the iron head is more convenient to operate and not easy to shift. Many SMT manufacturers often shift in the processing process is because of not cleaning the iron head or cleaning is not clean. When cleaning the tip of the iron, make sure not to use a sponge. Just tap on the tin and knock the tin off.

Two, fast

One of the tips for patch welding is to finish all the soldering before the flux on the solder evaporates. Because once the flux evaporates and the welding is not done, the solder will be dull, no flow, thick and brittle. At this time for welding, components are difficult to absorb on the pad, and easy to pull the point. Therefore, in the patch welding skills, fast is a very important and practical skill. Of course, if it is found that the flux has evaporated, there is also a remedy, which is to spot the flux in the tin wire, which can help with the next work.

Three, the standard

When sticking the component, be sure to let the component as close to the tip of the iron head as possible, but must not exceed the tip position. It is best to stick to the iron head at both ends as far as possible, so that when it is put on the pad, it can be in place in one step and done very accurately. The numerical side of the patch resistance should be oriented towards the soldering iron, so that the plate will not turn over. This patch welding technique needs to be mastered, and once mastered, there is no need to worry about it.

Iv. Stability

In the SMT patch processing process, the action must be stable, not too big, otherwise it is easy to bias other components, especially in the case of dense peripheral components, stability is very important. Because patch processing is a fine work, any step error may lead to the entire product scrap, so, pay attention to the stability of the movement at the same time, but also pay attention to the stability of the mentality. We should not be upset because of a momentary displeasure and affect the following work.

Five, how to restore the components

When you find that the position of the component is incorrect, you can use the patch welding technique, that is, add a little tin on the soldering iron, and then gently point at the top of the component, so that the fresh solder paste covers the solder spot before, and then after it melts, it will automatically return to the position, eliminate the point, very practical.

The above five points are SMT welding skills, but also SMT SMT manufacturers accumulated experience, very practical. Friends in need may wish to refer to it. Of course, these patch welding skills need to be mastered in practice, otherwise it is difficult to master the theory without practical operation.

2.smt patch processing and maintenance skills

First, tools and materials

In general, the common manual maintenance methods include two kinds, one is contact welding maintenance, the other is heated gas welding maintenance. Contact welding maintenance is done by direct contact with the solder joint on the heated iron head or ring. The iron ring is more suitable for removing adhesive bonded components, and has effect on rectangular or cylindrical components and integrated circuits, but has little effect on four sided plastic sealing components. In the process of manual welding maintenance, the need for flux and solder paste, the purpose is to let the solder, component pins, pads, etc., will not be quickly oxidized. At the same time, using the solder on the pad for welding, fixing components, reduce the occurrence of virtual welding, welding failures. In addition to the main tools and materials, manual maintenance also needs some auxiliary tools and materials, such as tweezers, vacuum suction pen, tin tape to clean pad, magnifying glass to check the quality, etc.

Two, smt patch processing and maintenance methods

The first kind: in the absence of a hot air gun, choose a clamp iron, clamp the element with a clamp iron on the IC side to prevent its displacement. The heat from the soldering tip is transferred to each pin as it melts. Therefore, it must be noted that the PLCC components removed by this method cannot be reused, and the high temperature of large melting area is easy to cause damage to the circuit board. Moreover, the low cost of the clamp iron is relatively high, and the weak smt patch processing manufacturers generally will not have. The second: the use of hot air gun blow welding. After all the pins are welded and melted, remove the IC and clean it up with a tin-absorbing tape. In smt patch processing and maintenance, manual operation is much easier than machine disassembly, and this method can also ensure that the loss of components is lower. Not only that, because it is manual operation and maintenance, so according to experience and professional knowledge, we can better judge the maintenance situation, make appropriate response according to the specific situation, remedy and reduce the loss. It is worth noting that the game industry circuit board is coated with protective glue, its purpose is waterproof, shockproof, in the process of manual maintenance, must be in the solder melt, use the hand tools to remove the protective glue and then take down the components. In addition, in the next step of operation, but also pay attention to the glue, otherwise the components will not be fixed firmly. Tips: smt patch processing and maintenance by hand, must have enough patience and operation skills, beginners only need to master, you can operate. Therefore, when choosing smt patch processing and maintenance manufacturers, we must choose professional, regular and powerful manufacturers, so as to ensure the maintenance effect and ensure the good quality of products in the future.