Usually the same area, the more PCB layers, the more expensive the price. The design engineer should use as few layers as possible to complete the PCB design while ensuring the quality of the design signal.

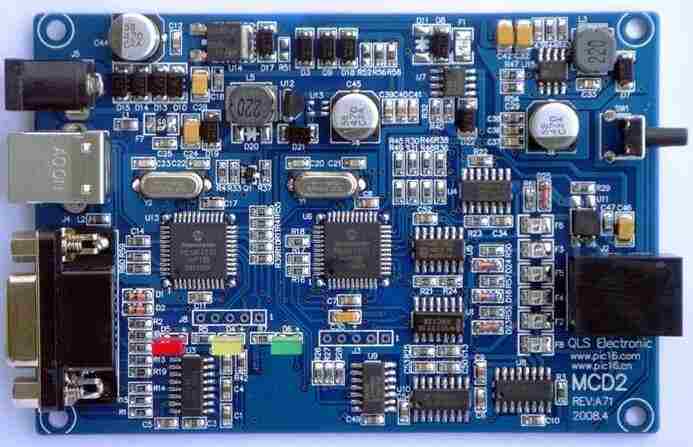

In PCB design, there are four main factors affecting the cost.

PCB layers

Usually the same area, the more PCB layers, the more expensive the price. The design engineer should use as few layers as possible to complete the PCB design while ensuring the quality of the design signal.

PCB size

In the case of a certain number of layers, the smaller the PCB size, the lower the price will be. In PCB design, if the size of PCB can be reduced without affecting the electrical performance, the size can be reduced reasonably and the cost can be reduced.

Manufacturing difficulty

The main parameters affecting PCB manufacturing include small wire width, small wire spacing, small drilling, etc. If these parameters are set too small or the process capacity has reached the small limit of PCB factory, then the PCB yield will be low and the cost of production and manufacturing will increase. Therefore, in the process of PCB design, try to avoid challenging the limits of the factory, set 20 reasonable line width and line spacing, drilling and so on. In the same way, through holes can complete the design. Try not to use the blind buried holes of HDI, because the processing technology of blind buried holes is much more difficult than through holes, which will increase the production cost of PCB.

PCB board material

PCB board classification is many, common paper based printed circuit board, epoxy glass fiber cloth printed circuit board rice composite substrate printed circuit board, special substrate printed circuit board metal substrate, etc. Different materials processing gap is very large, and some special materials processing cycle will be long, so in the design as far as possible to choose both can meet the design requirements, and relatively common affordable materials, such as RF4 materials.

Price and cost standard of circuit board

According to the different design of the circuit board, the price will be determined by the material of the circuit board, the number of layers of the circuit board, the size of the circuit board, the number of each production, the production process, the small line width and line distance, the small aperture and the number of holes, the special process and other requirements.

According to the different design of the circuit board, the price will be determined by the material of the circuit board, the number of layers of the circuit board, the size of the circuit board, the number of each production, the production process, the small line width and line distance, the small aperture and the number of holes, the special process and other requirements. There are mainly the following ways to calculate prices in the industry:

1, calculate the price by size (for small batch of samples)

The manufacturer will give the unit price per square centimeter according to different circuit board layers and different processes. The customer only needs to change the size of the circuit board into centimeters and then multiply the unit price per square centimeter to get the unit price of the circuit board to be produced. This calculation method is very suitable for the ordinary process of the circuit board, both convenient manufacturers and buyers. Here are some examples:

For example, a manufacturer pricing single panel, FR-4 material, 10-20 square meters of the order, the unit price is 0.04 yuan/square centimeter, then if the buyer's circuit board size is 10*10CM, the production quantity is 1000-2000 pieces, just meet this standard, the unit price is equal to 10*10*0.04=4 yuan a piece.

2, according to the cost of fine calculation price (for large quantities)

Because the raw material of the circuit board is copper clad plate, the production of copper clad plate factory set some fixed size on the market sales, common 915MM*1220MM(36"*48"); 940MM*1245MM

49 (37 "*"); 1020MM*1220MM(40"*48"); 1067mm*1220mm(42"*48"); 1042MM*1245MM(41"49"); 1093MM*1245MM(43"*49"); The manufacturer will calculate the copper clad utilization rate of this batch of circuit boards according to the materials, layers, processes, quantity and other parameters of the circuit boards to be produced, so as to calculate the material cost. For example, if you produce a circuit board of 100*100MM, the factory may assemble large boards of 100*4 and 100*5 to improve production efficiency. Among them, they also need to add some spacing and plate edge for convenient production. Generally, the spacing of the gong plate is 2MM, and the plate edge is 8-20MM, and then the large plate formed is cut in the size of the raw material. Here, if it is just cut, there is no excess plate, which is the utilization rate. Figuring out the utilization is only one step, but also the drilling cost, to see how many holes there are, how big the small holes are, how many holes there are in a big plate, and to figure out the cost of each small process such as copper plating cost according to the lines in the board, and then add the average labor cost, loss rate, profit margin, marketing expenses of each company. Then divide the total cost by how many small plates can be produced by a large piece of raw material to get the unit price of small plates. This process is very complex, the need to have a special person to do, the general offer will take more than a few hours.

3. Online meter

Because the price of circuit board is affected by a variety of factors, ordinary purchasers do not understand the quotation process of suppliers, often to get a price takes a long time, waste a lot of manpower and material resources, and because they want to know the price of a circuit board, they will give their personal contact information to the factory, which will bring follow-up continuous marketing. Many companies have started to set up a circuit board pricing program on their Web sites, with rules that allow customers to freely calculate prices. People who do not understand PCB can also easily calculate the price of PCB.

Maintenance costs do not exceed 30% of the original value of the electronic board, followed by the circuit board broken degree, the degree of difficulty, the number of parts, the cost of four aspects of charge, special cases, as appropriate.