Further Analysis of SMT Wire Mesh Wiping Paper

SMT wire mesh wiping paper, also known as SMT automatic wiping paper, SMT roller wiping paper, SMT dust-free roll paper, SMT wiping roll paper, etc

1. Information

With natural wood pulp and polyester fiber as raw materials, the unique spunlace process is adopted to form a unique wood pulp/polyester double-layer structure.

2. Effectiveness

Strong and durable, with high water absorption and oil absorption, soft, dust-proof and anti-static efficiency.

This material is soft and will not produce any scratches on the surface of the cleaned object, nor will it damage the surface of the object.

Can be used with cleaning solution.

Super liquid absorption capacity, more than four times faster than ordinary cotton wipes.

Effectively remove water and oil stains without using any chemical adhesive.

Since it is produced in the clean room, the impurities in the wiping paper are avoided, which can reduce the printing process

The mold will wipe the impurities carried and cause printing defects.

It can be matched with anti-static packaging to meet the strict anti-static requirements of electronic products.

3. Type

Plain paper and grid paper, imported UFP data

4. Parameters

Tissue weight 56, 60g, 65g, 68 g/m2

Thickness 0.3-0.35 mm

Width 20-800cm

5. Liner tube

Paper tube and PVC plastic tube.

The two ends of tubes used in different printing models should be either slotted or not.

6. Application

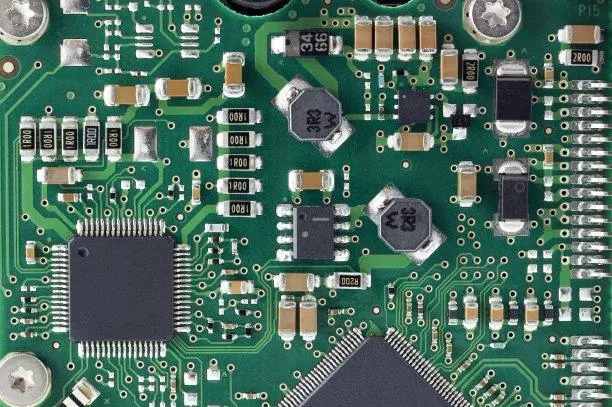

Used to clean high standard surfaces This is a special wiping paper SMT printing electronic industrial circuit board It can effectively remove the excess solder paste and red glue adhering to the printing press and the model of the circuit board, and keep the electronic circuit board spotless Greatly reduce the scrap rate, greatly improve production efficiency and product quality

It can be used in all automatic printing modes, such as MPM, DEK, KME, Yamaha, MINAMI, JUKI, EKRA, PANASERT, Fuji, Sanyo, etc.

7. Specifications

The width and length of the dust-free paper and the diameter and length of the inner tube are determined by the size and model of the actual printed product.

8. Opening

Operators who often use SMT mould wiping paper may have this problem, that is, some products are very effective in use, but some products are very unsatisfactory in use. The reason for this problem is that some factors will affect its use.

1. It is related to the retention rate of fine fibers in the molding section: in the production process, we usually use 80 mesh carbon mesh, and the fine fibers below 1mm account for about 5% of the total fibers. If the vacuum degree of the molding part is controlled, the bulkiness of the SMT model wiping paper can be improved by reducing the loss rate of fine fibers or recycling.

2. Fluff pulp factor: the longer the fiber of fluff pulp is, the higher the roughness is, and the better the fluffy degree of the final paper is; The bulkiness of kraft pulp is better than that of kraft pulp; The bulkiness of softwood pulp is better than that of hardwood pulp; The untreated pulp has better expansibility than the treated pulp.

3. This is related to the texture of the transfer mesh (embossed mesh) used. The puffiness of SMT screen paper made of plain fabric is much better than that of other large screens;

4. Temperature of compactor and embossing machine: the higher the pressure, the tighter the SMT mold paper will be pressed, the worse the bulkiness, and the smaller the thickness;

5. High quality products are heavier than low quality products. This is because a large number of products have high retention of fine fibers in the molding process. On the other hand, a high number of product organizations use relatively low amounts of glue.

For SMT mould wiping paper, besides the above five factors, the main factor affecting the volume and thickness index is the temperature of the oven Within the allowable range of the production process, if the temperature is high, the hot-melt bonding is better, and the volume and thickness are larger

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.