The minor editor of the electronic factory explains the influence of PCBA design defects on cleaning

PCB manufacturers, PCB designers and PCBA manufacturers explain the impact of PCBA design defects on cleaning

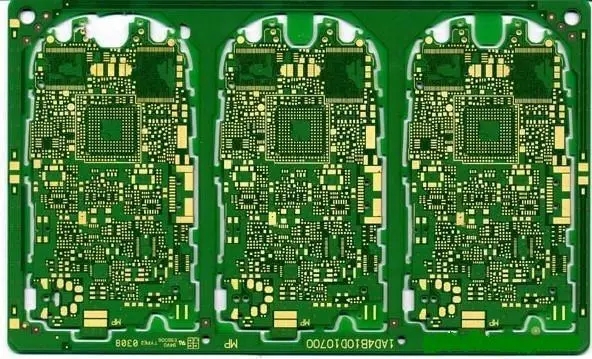

PCBA processing is more and more widely used in the market. Thanks to its unique role, it can effectively solve many problems. In the electronic industry, it is also popular with consumers. The residual welding fluid on the surface (around the buried hole) and the notes of spot welding cannot be completely removed, especially the bottom of a few inches of integrated IC.

The disadvantages of PCBA design scheme mainly include that the spacing of electronic devices is too small, the installation of electronic devices does not leave enough space in the board room, and the electronic devices or components are hidden or masked so that they cannot touch and guide the buried holes.

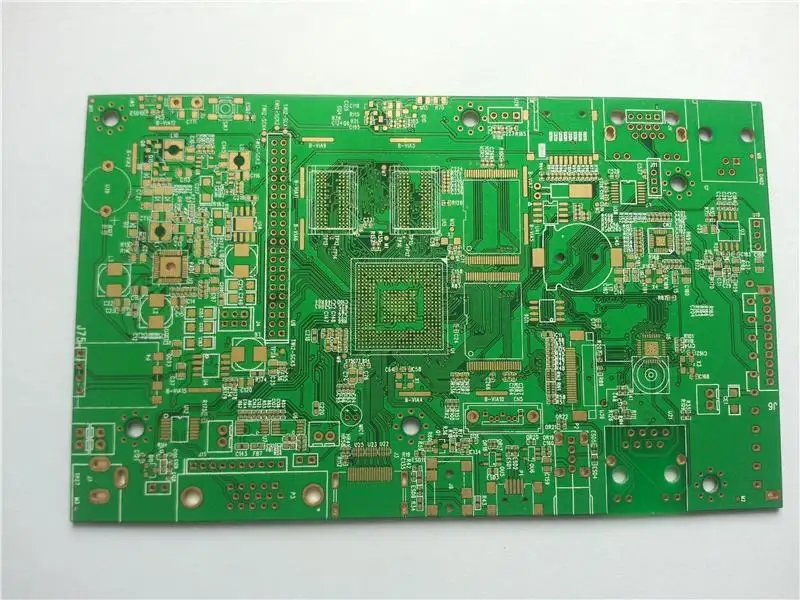

Solder paste is a kind of centrifugal separation compound, which is made of aluminum alloy welding powder, viscous flux and some preservatives. It is a paste with certain viscosity and excellent thixotropy.

This is a homogeneous, stable compound. At normal temperature, the solder paste can initially stick the electronic components to specific parts. When the solder paste is heated to a certain temperature, along with the evaporation of organic solvents and some preservatives, and the melting of alloy powder, the solder paste will flow again during PCBA processing, making the electronic components to be welded and the through-hole interconnected together to generate permanent spot welding through refrigeration. Different solders shall be selected for different PCBA products. The composition, purity and oxygen content of aluminum alloy solder paste powder, the appearance and specification of particles, and the composition and characteristics of flux are the primary conditions for determining the characteristics of solder paste and spot welding quality.

PCB manufacturers, PCB designers and PCBA processors will explain the impact of PCBA design defects on cleaning.