Automotive Electronics PCB Assembly

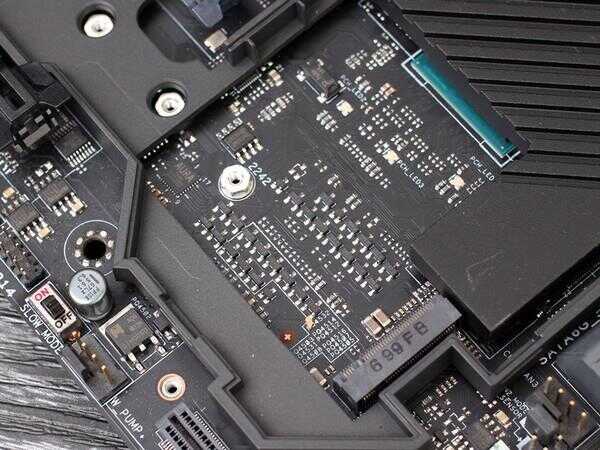

Name: Automotive Electronics PCB Assembly

Substrate: FR-4/High TG/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea

Automotive electronics is the general term for car body electronic control devices and vehicle electronic control devices. Car body electronic control device, including engine control system, chassis control system and body electronic control system (body electronic ECU). The most important role of automotive electronics is to improve the safety, comfort, economy and entertainment of the car. An electronic control system composed of sensors, microprocessor MPU, actuators, dozens or even hundreds of electronic components and parts. The degree of automotive electronics is regarded as an important indicator to measure the level of modern automobiles, and it is the most important technical measure used to develop new models and improve automobile performance.

Technical status

Automobile electrification is considered to be a revolution in the development of automobile technology. The degree of automotive electronics is regarded as an important indicator to measure the level of modern automobiles, and it is the most important technical measure used to develop new models and improve automobile performance. Automakers believe that increasing the number of automotive electronic devices and promoting automotive electronics is an important and effective means to capture the future automotive market.

According to statistics, from 1989 to 2000, the average proportion of electronic devices on each car in the entire car manufacturing cost increased from 16% to more than 23%. On some luxury cars, the number of single-chip microcomputers used has reached 48, and electronic products account for more than 50% of the cost of the vehicle.

Apply changes

The application of automotive electronic technology will bring about the following major changes in the car:

The mechanical structure of automobiles will undergo major changes, and the various control systems of automobiles will develop towards electronization and electrification, realizing "wire control". Replace the original mechanical transmission mechanism with wires, such as "wire brake", "wire steering", "electronic throttle" and so on.

The car's 12-volt power supply system is converted to 42-volt. With more and more electronic devices in cars, the power consumption is increasing dramatically. Existing 12-volt power supply cannot meet the needs of all electrical systems on the car. In the future, the integrated starter-generator 42-volt power supply system will be adopted. The maximum output power of the generator will be increased from 1 kW in 2005 to about 8 kW, and the power generation efficiency will reach more than 80%. The implementation of the new standard for the 42-volt automotive electrical system will cause major changes in the design and structure of automotive electrical components, and mechanical relays and fuse protection circuits will be eliminated.

The application of automotive electronic technology will make the car more intelligent. Smart cars are equipped with a variety of sensors, which can fully perceive the conditions of drivers and passengers, information about traffic facilities and the surrounding environment, judge whether the occupants are in the best condition, whether vehicles and people are in danger, and take corresponding measures in time.

Today, society has entered the age of information networks. People hope that the car is not only a means of transportation, but also an extension of the scope of life and work. In the car, it is like staying in your own office and home, and you can listen to Broadcast, make phone calls, surf the Internet, do work. With the advancement of digital technology, cars will also enter the multimedia era. The vehicle-mounted computer multimedia system developed by using the WINDOWS operating system has the functions of information processing, communication, navigation, anti-theft, language recognition, image display and entertainment. In the foreseeable future, cars will be equipped with automatic navigation and assisted driving systems. The driver can input the driving destination into the car computer, and the car will drive to the destination along the best driving route. People can manipulate various facilities in the car through the language recognition system, while driving the car, while enjoying music TV, they can also book dinner tables, air tickets, etc.

Category introduction

According to the impact on the driving performance of the car, automotive electronic products can be classified into two categories: one is the automotive electronic control device, and the automotive electronic control device must be used in conjunction with the mechanical system on the car, that is, the so-called "mechanical and electrical" car Electronics; they include engine, chassis, body electronic controls. Such as electronic fuel injection system, brake anti-lock brake control, anti-skid control, traction control, electronically controlled suspension, electronically controlled automatic transmission, electronic power steering, etc. The other type is on-board automotive electronic devices. An electronic device that can be used independently in the environment, it is not directly related to the performance of the car itself. They include car information system (trip computer), navigation system, car audio and TV entertainment system, car communication system, Internet equipment, etc.

In 2008, the direction of electronic technology development was towards centralized integrated control: the engine management system and the automatic transmission control system were integrated into the comprehensive control (PCM) of the power transmission system; the anti-lock brake control system (ABS), traction control System (TCS) and drive anti-skid control system (ASR) are integrated together for braking control; through the central chassis controller, control systems such as braking, suspension, steering, and power transmission are connected through the bus. The controller coordinates various subsystems through complex control calculations to control the vehicle's driving performance to the best level, forming an integrated chassis control system (UCC).

Due to the sharp increase in the number of electronic and electrical devices on automobiles, in order to reduce the number and weight of connecting wires, network and bus technologies have developed greatly during this period. Bus technology is to connect various automotive electronic devices into a network, and send and receive information through the data bus. In addition to completing their own control functions independently, the electronic devices can also provide data services for other control devices. Due to the use of network design, the wiring is simplified, the number of electrical nodes and the amount of wires are reduced, the assembly work is simplified, and the reliability of information transmission is also increased. Through the data bus, any electronic control device can be accessed, and the fault code can be read to diagnose its fault, which makes the maintenance work of the whole vehicle easier.

Seven characteristics

Automotive electronic information products are a big market, and the market will grow by 7% annually, and the market for vehicle telematics systems will reach 20 billion US dollars. According to experts from the Auto Products Home community, with the rapid development of my country's auto industry, my country's auto electronics industry presents seven major development characteristics:

1. The automobile industry is in the era of technological innovation. Traditional mechanical and electrical products have become high-tech products, and the automobile industry has become an industry equipped with high-tech equipment.

2. Regulations and markets promote the development of automotive electronic information technology. Energy, emission, noise, and safety regulations are becoming increasingly stringent, and customers' requirements for comfort are constantly improving, which promotes the development of automotive electronic information technology. my country will also implement the Euro III emission standard, and Europe will implement the Euro IV emission standard. Germany has developed a car with a fuel consumption of one liter per 100 kilometers. Seat belts, airbags, ABS, ASR, etc. that improve car safety have all been intelligentized.

3. The scale of automobile and engine system microprocessors is getting bigger and bigger. There are more and more automotive microprocessors, and some models have as many as 60, and they are controlled by LIN and CAN networks. Automotive electronic products account for 1/3 of the total cost of the car, and the software part accounts for 4%. 10%. ICs will also continue to be integrated, and one IC today can perform functions equivalent to multiple ICs in the past. In order to meet the development needs of electronic systems, the automotive power supply system will develop from 12V to 42V.

4. The electronic control and electronic injection system will be popularized to improve the efficiency of the power system. It can be seen that all engines have adopted electronic technology, and manufacturers are also popularizing and improving: electronically controlled high-pressure common rail diesel engines are being researched extensively, and power electronic module hybrid drive systems New progress has been made in the commercialization of hydrogen fuel cell hybrid vehicles, electronically controlled composite spark ignition engines are rapidly popularizing, and advanced electronically controlled uniform charge and compression ignition engines are being researched intensively.

5. The control-by-wire or drive system is developing rapidly. The research on steering-by-wire and brake-by-wire is being intensified. The control-by-wire will replace the mechanical system, and the automobile chassis will undergo revolutionary changes.

6. ITS is rapidly emerging, including intelligentization of automobiles, automation of highways and navigation systems.

7. Integrated control has become the development trend of automotive electronic information technology, including power transmission system, chassis and safety system, body and anti-theft system, etc. The telematics system will make Bluetooth technology widely used in automobiles, and the intelligentization of automobiles will continue to upgrade.

An Introduction

Product Development Process

Vehicle control electronic products are embedded systems that combine software and hardware. In order to save resources and shorten the product development cycle, generally the software and hardware should be developed synchronously. The development tools of vehicle control electronic products provide good support for the simultaneous development and debugging of software and hardware. The software development of vehicle control electronic products is divided into steps such as function description, software design, code generation, and advanced debugging under the operating system environment. The hardware development of vehicle control electronic products is divided into steps such as hardware description, hardware design, and hardware debugging. After the software design is completed, the verification on the virtual ECU platform is completed by using corresponding tools. After the hardware design is completed, the hardware and software integration debugging is carried out together with the hardware. Through this development method, the time to market of the product is shortened. Software and hardware parallel development scheme

Product software development process

The software development process of automotive control electronics products is a "V"-shaped development process. The "V"-shaped development process is divided into five stages, namely, functional design, prototype simulation, code generation, hardware-in-the-loop simulation-HIL, and calibration.

The main tool used in the functional design phase is MATLAB. Through the use of SIMULINK, STATEFLOW and other tools provided by MATLAB, tasks such as control scheme design, function module design, and control algorithm design are completed, and preliminary simulation work is carried out. The main tool used in the prototype simulation phase is DSPACE. Use the Rapid Control Prototyping-RCP tool provided by DSPACE to complete the off-line simulation work. Before starting this stage, it is necessary to use tools such as REAL TIME WORKSHOP and TARGETLINK to complete the conversion of codes generated by SIMULINK, STATEFLOW, etc. to standard C codes.

Code generation process

In the process of converting to standard C code, an embedded real-time operating system that conforms to the OSEK specification can be added as needed. The main tool used during the code production phase is CODEWARRIOR. By using the compiler, debugger and other tools provided by CODEWARRIOR, complete the conversion from standard C code to product code on the target hardware platform. The figure below shows the code generation process of the vehicle control electronic products. Electronic Product Code Generation Process

Automotive Electronics System Division

Automotive electronic products can be divided into two categories: 1. Automotive [3] electronic control devices, including powertrain control, chassis and body electronic control, comfort and anti-theft systems. 2. Car electronic devices, including car information system (car computer), car tire pressure monitoring system, navigation system, car audio-visual entertainment system, car communication system, car network, reversing image rear view system, car navigator rear view camera, etc. .

The figure below shows a schematic diagram of the division of the automotive electronic system. The future market of automotive electronics tends to be more secure. It can be seen from the market demand that people pay a lot of attention to safe driving technology and products. We've made significant advances in passive safety technology—that is, technologies and products that protect drivers and passengers in the event of a car crash, such as crash sensors, air bags, seat belts, follow-up steering structures, and sheet metal impact zones And other products and technologies have saved many lives and reduced injuries in car crashes. But the latest development is active safety, which uses technology such as radar, optical and ultrasonic sensors to measure the distance of the car to surrounding objects and the speed of approaching objects. This data can be used to remind the driver to control the driving speed of the car and avoid possible collisions. This information can also be used to control the brakes or steering systems to automatically avoid collisions. This collision avoidance system can reduce the global accident rate and the high cost of automobile accidents.

Application status

Application on the engine:

Electronically controlled fuel injection device

In modern automobiles, mechanical or electromechanical hybrid fuel injection systems have become obsolete, and electronically controlled fuel injection devices have become increasingly popular due to their superior performance. The electronic fuel injection device can automatically ensure that the engine is always working in the best condition, so that it can save fuel and purify the air to the greatest extent under the condition of outputting a certain power. After experiments and corrections, the oil supply control law of the engine in the best working condition is obtained, and these objective laws are programmed into the memory of the microcomputer in advance. When the engine is working, according to the air flow measured by each sensor and the content Oxygen amount, intake air temperature, engine speed and working temperature and other parameters are calculated according to the pre-programmed calculation program, and then compared and judged with the parameters of the best working condition in the memory to adjust the fuel supply. In this way, the engine can always be operated under optimal working conditions, so that the overall performance of the engine can be improved.

Electronic Ignition (ESA)

It is composed of several parts such as microcomputer, sensor and its interface, and actuator. The device can calculate and judge according to various parameters of the engine sent by the sensor, and then adjust the ignition time, which can save fuel and reduce air pollution. In addition, the new engine electronic control device also has adaptive control, intelligent control and self-diagnosis operation. It is generally believed that the energy-saving effect of the engine electronic control device is more than 15%, and the effect is more obvious in terms of environmental protection.

In addition, the use of electronic technology in the engine part also includes: exhaust gas recirculation (EGR), idle speed control (ISC), electric oil pump, generator output, cooling fan, engine displacement, throttle timing, secondary Air injection, engine boosting, oil vapor evaporation and system self-diagnosis functions, etc., are more or less applied in different models.

Related application

Electronically Controlled Automatic Transmission (ECAT)

ECAT can automatically change the position of the gear lever after the calculation and judgment of the computer according to the engine load, rotational speed, vehicle speed, brake working status and various parameters controlled by the driver, so as to realize the optimal control of transmission shifting, that is, The best gear and the best shift time can be obtained. Its advantages are good acceleration performance, high sensitivity, and can accurately reflect driving load and road conditions. The electronic control device of the transmission system can automatically adapt to the instantaneous working conditions and keep the engine working at the lowest possible speed. The electro-pneumatic shifting device uses an electronic device to replace the mechanical shift lever and its connection with the transmission mechanism, and is implemented through a solenoid valve and a pneumatic servo valve cylinder. It not only significantly simplifies vehicle handling, but also achieves optimum driving dynamics and safety.

Anti-lock braking system (ABS)

The system is an important safety component with the longest development time and the fastest promotion and application. It ensures the best slip ratio (15-20%) between the wheel and the ground by controlling the locking of the wheel to prevent the car from braking, so that when the car brakes on various roads, the wheel and the ground can reach the longitudinal peak Adhesion coefficient and large lateral adhesion coefficient to ensure that the vehicle does not have unsafe working conditions such as locking and slipping, loss of steering ability, etc. during braking, improve the handling stability and safety of the vehicle, and reduce the braking distance. Anti-skid system (ASR), also called traction control system (TCS or TRC), is the perfection and supplement of ABS. Improve its operational stability.

Electronic Power Steering System

The electronic steering assist system uses a DC motor to replace the traditional hydraulic booster cylinder, and uses a battery and an electric motor to provide power. Compared with the traditional hydraulic power assist system, this microcomputer-controlled steering assist system has the characteristics of fewer components, smaller size, and lighter weight. The optimized steering force and steering return characteristics improve the steering ability and steering response characteristics of the car. , which increases the maneuverability of the car at low speeds and adjusts the stability of driving.

Adaptive Suspension

The adaptive suspension system can automatically and timely adjust the stiffness of the suspension spring and the damping characteristics of the shock absorber according to the instantaneous load of the suspension device, so as to adapt to the load at that time and maintain the predetermined height of the suspension. In this way, the driving stability, handling and riding comfort of the vehicle can be greatly improved.

Automatic Control System (CCS)

When driving at high speed for long distances, the constant speed cruise automatic control system can be used. The constant speed driving device will automatically adjust the throttle opening according to the driving resistance, and the driver does not have to step on the accelerator frequently to adjust the vehicle speed. If there is a downward trend in the vehicle speed when climbing a slope, the microcomputer control system will automatically increase the throttle opening; when going downhill, it will automatically close the throttle opening to adjust the engine power to a certain speed. This control system is automatically disengaged when the driver shifts down or brakes.

With the world's major automobile manufacturers attaching great importance to automobile safety issues, new electronic technologies have been widely used in airbag systems, driving dynamics adjustment systems (FDR or VDC), anti-collision systems, seat belt control, and camera control.

Develop

Whether the market center of gravity shifts to developing countries or the technology center of gravity shifts to electronic technology, it will inevitably affect the development direction of automotive electronics. Moreover, its technology itself will also face stringent requirements from various aspects of performance, safety and environmental protection regulations. According to the "2013-2017 China Automotive Electronics Industry Market Competition Pattern Analysis Report", in the next 10 years, electronic technology will play a big role in the automotive industry. Through comprehensive investigation and research on the global trends driving the development of new technologies, products and markets around the world, it is found that the future of the automotive electronics industry is green, environmental protection, safety and connectivity.

Environmental protection: The main development trend of the global automobile industry is to develop engines with high fuel efficiency and low carbon emissions.

Security: The second major trend in the development of automotive electronics is security. The market has a huge demand for technologies and products that can ensure safer driving.

Connected communication: The third major trend in the development of automotive electronics is the communication connectivity of the car.

The automobile society will enter the era of Internet of Vehicles

The Internet of Vehicles is actually a new network that combines the Internet and the Internet of Things with vehicles as the main body. Smart cars in the era of "Internet of Vehicles" have the following characteristics: first, a relatively fixed distance can be maintained between cars and zero collisions can be achieved; The destination, through GPS positioning and automatic communication between vehicles, vehicles can temporarily form or leave teams to improve traffic efficiency.

Kingford supports Automotive Electronics PCB Assembly business, we are a professional PCBA one-stop assembly factory, welcome to place an order.

Name: Automotive Electronics PCB Assembly

Substrate: FR-4/High TG/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea