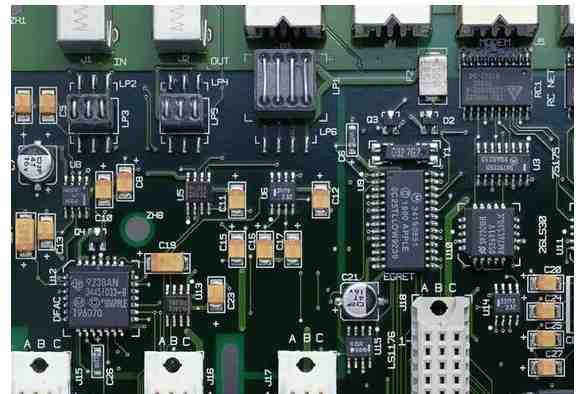

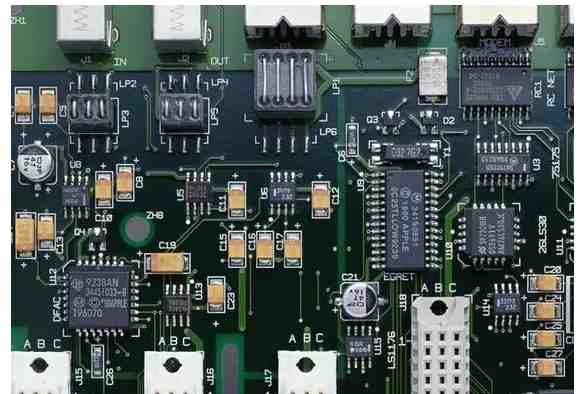

A good circuit board, in addition to the realization of the circuit principle function, but also to consider EMI, EMC, ESD (electrostatic discharge), signal integrity and other electrical characteristics, but also to consider the mechanical structure, large power chip heat dissipation problems, on this basis to consider the beauty of the circuit board, just like artistic engraving, every detail of its consideration. Carry on

The following aspects are often considered in the layout of PCB components.

1. Does the PCB board shape match the whole machine?

2. Is the spacing between components reasonable? Is there a level or high level of conflict?

3. Does the PCB need to be assembled? Are craft edges reserved? Are installation holes reserved? How to arrange the positioning holes?

4. How to place the power module and dissipate heat?

5. Are components that need to be replaced frequently placed in a convenient location? Are adjustable elements easy to adjust?

6. Is the distance between the thermal element and the heating element considered?

7. What is the EMC performance of the whole board? How to layout can effectively enhance anti-interference ability?

For the problem of spacing between components and components, based on the distance requirements of different packages and the characteristics of Altium Designer itself, if the rule setting is restricted, the setting is too complex and difficult to achieve. Generally, lines are drawn on the mechanical layer to mark the peripheral dimensions of the components, so that when other components are close, they are roughly known. This is very practical for beginners, but also enable beginners to develop good PCB design habits.

Through the above consideration analysis, the common PCB design layout constraint principles can be classified as follows.Element arrangement principle

1.Under normal conditions, all components should be arranged on the same surface of the PCB, and only when the top component is too dense, some components with limited height and small heat generation (such as patch resistors, patch capacitors, patch ics, etc.) can be placed on the bottom.

2. Under the premise of ensuring electrical performance, the components should be placed on the grid and arranged parallel or vertical to each other in order to be neat and beautiful. Under normal circumstances, components are not allowed to overlap, component arrangement should be compact, input components and output components as far away as possible, do not cross.

3. There may be a high voltage between some components or wires, and the distance between them should be increased to avoid accidental short circuit due to discharge and breakdown, and the layout should pay attention to the layout space of these signals as much as possible.

4. Components with high voltage should be arranged as far as possible in places that are not easily touched by the hand during debugging.

5. The components located at the edge of the plate should be as close as possible to the edge of the plate with a distance of two plates thick.

6. The components should be evenly distributed on the entire board, not in this area dense, another area loose, improve the reliability of the product. Follow the signal direction layout principle.

After placing the fixed components, arrange the position of each functional circuit unit one by one according to the direction of the signal, with the core component of each functional circuit as the center, and carry out local layout around it.

The layout of the components should be convenient for signal flow, so that the signal is as consistent as possible. In most cases, the flow direction of the signal is arranged from left to right or from top to bottom, and the components directly connected to the input and output terminals should be placed near the input and output connectors or connectors.

Protection against electromagnetic interference

1.For components with strong radiation electromagnetic fields and components that are more sensitive to electromagnetic induction, the distance between them should be increased, or consider adding a shield to shield them.

2. Try to avoid high and low voltage components mixed with each other and strong and weak signal components interlaced together.

3. For components that generate magnetic fields, such as transformers, speakers, inductors, etc., the layout should pay attention to reducing the cutting of magnetic field lines on printed wires, and the magnetic field direction of adjacent components should be perpendicular to each other to reduce the coupling between each other. Figure 9-2 shows the inductor and inductor are arranged 90° vertically.

4. Shield interference sources or modules that are susceptible to interference, and the shield should be well grounded. Figure 9-3 shows the planning of a shield. Suppression of thermal interference.

Principle of adjustable component layout

For the layout of adjustable components such as potentiometers, variable capacitors, adjustable inductors, microswitches, etc., the structural requirements of the whole machine should be considered: if the machine is adjusted externally, its position should be adapted to the position of the adjustment knob on the chassis panel; If it is adjusted in the machine, it should be placed on the PCB where it is easy to adjust

kingford Electronics is a professional PCB design company engaged in electronic product circuit board design (layout layout design), mainly undertake multi-layer, high-density PCB design and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier!