In multi-layer PCB design, GND layer and power layer will be indented to a certain extent, why should they be indented? Next, the PCB design company introduces the reasons for the internal shrinkage design of the GND layer and the power layer of the next multi-layer PCB design.

To understand this problem, we need to first understand a knowledge point, that is, the "20H" principle:

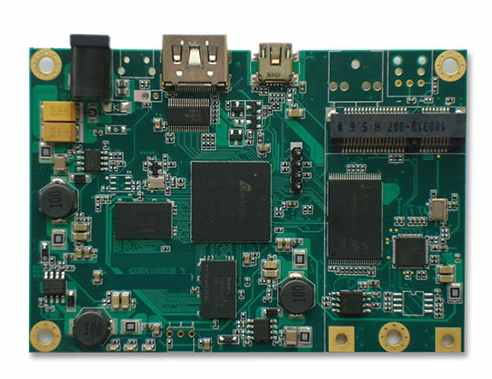

The 20H principle is mainly put forward in order to reduce the electromagnetic radiation of the circuit board. If there is a high-speed current on the circuit board, there is a magnetic field related to it. At the edge of each layer, the radiation mode of the electromagnetic field is shown as follows:

It can be seen that when the upper and lower planes of the stratum and the power layer are the same size, electromagnetic interference will be radiated outward at the edge of the board because the electric field between the power layer and the stratum is changed. Generally, the solution is to shrink the power layer to a certain distance, so that the electric field can only be conducted within the range of the stratum, so as to inhibit the edge radiation effect. Improve electromagnetic compatibility (EMC).

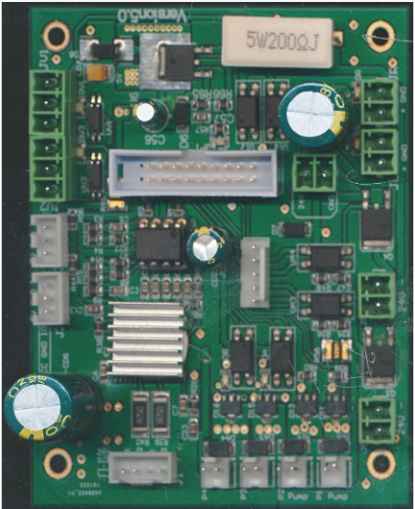

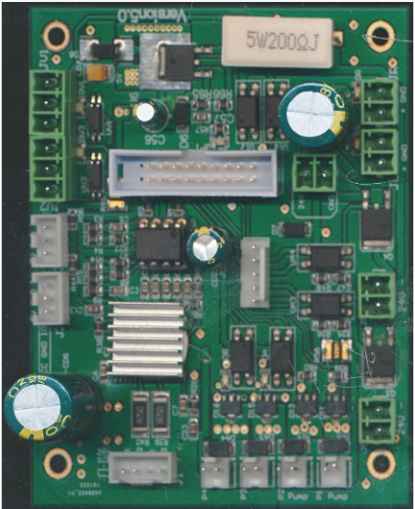

So how much distance do we generally shrink, the distance we shrink is the distance we said before "20H", this H refers to the thickness of the medium between the power layer and the formation, the adoption of the "20H rule" is to ensure that the edge of the power plane is at least 20 times the equivalent of the distance between the two planes than the edge of the 0V plane.

As shown in the figure above is the power plane and the ground plane after the internal contraction, we can see that most of the electromagnetic field will not radiate out, so as to reduce the external EMI radiation, but why do we say that most will not radiate out? Because we found that the power supply is indent by 20H relative to the edge of the formation, then the density of the electromagnetic field can be reduced by about 70%, not to say that it can be reduced to zero, then if we need to contain more electric fields, we can contain "100H", in general, 100H can contain 98% of the electric field. So that's one reason why our boards need to be indented, However, due to the laminated design, on some common PCB boards, if it strictly meets 20H, PCB wiring can not be carried out, so the general treatment method is that the power GND is reduced by 1MM relative to GND, so that the performance of our board is also guaranteed.

We also need to note that our 20H principle can have obvious effects under certain conditions.

1, the power plane should be inside the PCB, and the upper and lower layers adjacent to him are 0V planes, and the distance between the two 0V flat faces should be at least 20 times the distance between them and the power plane.

2, the total number of PCB layers should be greater than or equal to 8 layers.

Maximum signal design rate: 10Gbps CML differential signal; Maximum PCB design layer: 40 layers;

Minimum line width: 2.4mil; Minimum line spacing: 2.4mil;

Minimum BGA PIN spacing: 0.4mm; Minimum mechanical hole diameter: 6mil; Minimum laser drilling diameter: 4mil;

Maximum number of pins:; 63000+ Maximum number of components: 3600; Maximum number of BGA: 48+.

kinhford Electronics is a professional PCB design company engaged in electronic product circuit board design (layout layout design), mainly undertake multi-layer, high-density PCB design and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier!