What do PCB positive and negative mean? What's the difference?

Many friends do not know the meaning of PCB positive and negative? What's the difference?

Usually the solution used in the negative film manufacturing process is the acid-base corrosion process. After making the film, the required path or copper surface is completely transparent, while the unwanted part is black. After exposure to the line process, due to the exposure of the dry film inhibitor to ultraviolet light, the completely transparent part will be chemically hard bottom, and the development process below will not harden the film, the dry film will be washed away, so during the etching process, only the copper deposition of the dry film washed away part (the black part of the negative), and the preserved dry film is not washed away. This is the PCB we want (the transparent part of the negative).

Usually the positive process is based on the alkaline etching process. On the negative, the required path or copper surface is black, while the unwanted part is completely transparent. Similarly, after the line process exposure, the completely transparent part is hardened by the chemical action of the dry film blocker exposed to ultraviolet light, and the subsequent development process will wash away the dry film without hard substrate in the next step. We use an alkaline solution to remove the copper surface without tin and lead maintenance (the transparent part of the negative), leaving the PCB (black film) part.

1.Distinguish screen printing screen plate (negative), working film, positive film and negative film and film surface: screen printing screen has a mother film and working film (subfilm), black and yellow film, positive and negative film;

2. Negative is also called black film, also known as carbon negative. However, the working negative is not only yellow film, but also black film to finish the piece. It is mainly used for manufacturing high-precision HDI boards or cost saving, one-time mass production and manufacturing of PCB boards in small batch production applications.

3. When the surface of the film is different, the bright surface of the black film is the film, and the yellow film is the opposite. In general, it can be seen that the side is based on the doodle pen or knife tip on the screen printed film surface.

4. Yellow film application notes: there are two kinds of smooth and matte surface, the second kind of application is easy to appear oil surface indentation.

5. The negative film (containing copper) that transmits light on the membrane circuit is a positive film; The positive film is used in the graphic plating process, the developer drop is the path, the residual effect is the corrosion resistant plating process, the key inlays are lead and tin. Film is usually used in the instant etching process, corrosion resistance after the developer is the way, and acid-base etching solution is used to carry out the instant etching process.

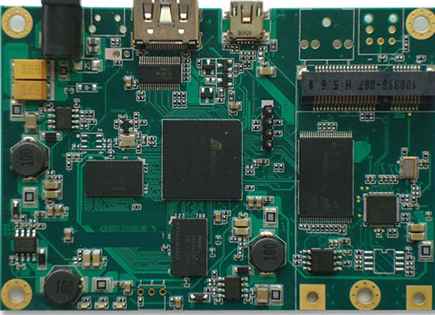

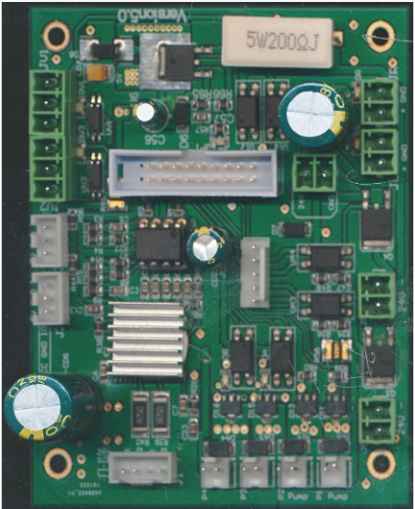

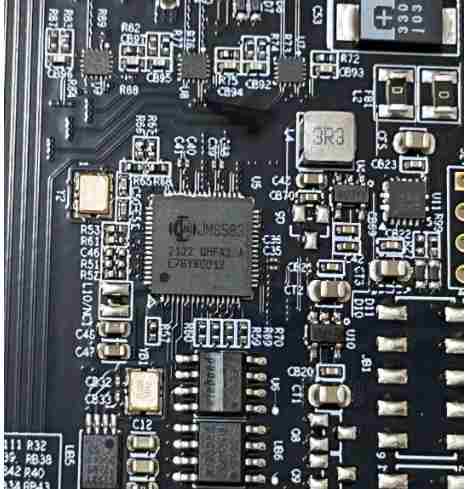

Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production.

Minimum line width/spacing: 3mil/3milBGA Spacing :0.20MM Minimum aperture: 0.1mm Size :610mmX1200mm

Ink: Japan Tamura, Taiyo, Fudoken;

FR4: Sheng Yi, Kingboard, Hai Hai, Hongren, Guoji, Hezheng, Nan Ya, (Sheng S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency board: Rogers, Taconic, ARLLON; Surface process: spray tin, lead-free spray tin, sinking gold, full plate gold plating, plug gold plating, full plate thick gold, chemical sinking tin (silver), anti-oxidation (OSP) blue glue, carbon oil

kinhford Electronics is a circuit board manufacturer specializing in printed circuit board manufacturing, 20 years of focus on single, double sided, multi-layer circuit board production. Can provide FR4 hard board, FPC soft board, HDI board, metal substrate PCB proofing and mass production services.