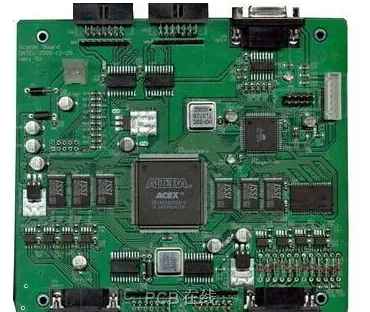

Printed circuit boards are an integral part of many electronic devices. If you plan to buy a PCB, you should learn more about the design process. This way, you can ensure that the board is perfectly suited for your desired application. In addition, you will optimize costs and maximize the price of the board. The following is to introduce the basic PCB elements and PCB design and production process.

Overview of basic PCB elements

Before we discuss what you need to know about PCB design and manufacturing, we'll walk you through the basic components of each printed circuit board.

1.1. Layers Each board contains layers, and the number of layers you choose depends on your desired application.

The general rule is that the more layers you choose, the more complex the PCB will become.

That's why building boards with more layers can take more time, though well-known companies still manufacture them quickly.

Here are some common choices people make when assembling PCBS: two-layer - a board that is relatively easy to make and used for simple products such as toys;

Layer 4 - a solution that many people use for Internet of Things (IoT) projects; Six to eight layers - you'll see these in tech-related devices like smartwatches and smartphones.

If you are sure you are looking for the simplest solution, manufacturers will also accept single-layer boards.

You can also use more than eight layers, but make sure your application needs that many. Otherwise, you'll be paying more for no reason.

1.2. Size and thickness

Next, you need to determine the size and thickness of the board. As for the size, the only important factor to consider is that it fits perfectly into your application.

This is why you should consider the size of the product and measure the space where you plan to place the PCB.

You must measure the dimensions accurately because there is not much room for error if you want your product to work properly.In terms of thickness, it can range from about 0.5 mm to 2.5 mm. You should consider your application and decide accordingly, but the average thickness is about 1.2-1.8mm.

1.3. Other things to considerHere's a list of other components and features you might want to consider when ordering your PCB:

Materials - Common choices include standard FR4, FR4-TG170, and halogen-free materials.

Color - You can use solder resistance layers in red, green, yellow, blue, etc.

Finish - Lead-free or leaded HASL, different silver, gold and tin impregnations are available.

Copper weight - you can choose the desired thickness of each layer, ranging from 0.5 oz to 4 oz. Copper is used because of its high electrical conductivity.

Second, pcb Design and manufacturing --Design Process

The design process begins with circuit design. The first thing you need to do is take out a document called a schematic. You can think of it as a blueprint that shows all the components and how they communicate in detail.

You can design circuits on a PC using professional software, such as Quadcopter, Altium, ExpressPCB, or many other software available online.

Keep in mind that most of these tools are paid versions, so you'll have to buy them if you want to design your own PCB. What you need to know about PCB design and manufacturing is the specifications of each component to be included on the board. The schematic can greatly help with the next step, which is the PCB layout.

PCB design and manufacturing

2.1. Assign components to their locations

Each component needs to have a precise location during the manufacturing process. This is why creating a board layout is a crucial step in PCB design.

This can be tricky because you need to find the best way to fit all the components and explain how to connect them. This is why assembling PCBS with more layers is more challenging.

The strategy adopted by most designers is to use different areas for different purposes.

The components associated with the power supply are located in one section, the audio output is located in another, and so on. Grouping is crucial because it saves space and controls noise and interference. Leds, connectors, audio jacks, and other important user experience items must be considered. You want to maximize availability so that you can use the PCB effortlessly.

The final step is to generate a Gerber file, which is a standard printed circuit board manufacturing format.

You may think that designing a PCB is easy, but it is tricky to place all the components correctly.

You need to avoid interference and other potential problems while maximizing the user experience, and only a professional PCB design company can do this job

Third, pcb design and Manufacturing --Manufacturing Process

After the design of the PCB is ready, it can be manufactured. The easiest way to do this is to send the Gerber file to the manufacturer and let them work their magic.

They will use layouts to assemble PCBS and turn ideas into reality. If you choose a professional manufacturer, they will most likely have all the necessary materials ready.

This will eliminate the need to order materials and wait for delivery. Instead, they can start manufacturing immediately.

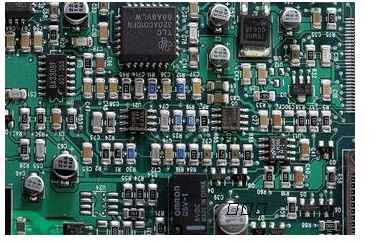

3.1. Install PCB componentsThe main task in the assembly process is to mount the component to the board surface. There are two ways to do this:

Surface mount technology (SMT) is very convenient when manufacturing many PCBS. Reliable and fast professional tools handle installation to ensure that there is no room for human error while speeding up the process.Through hole - Some people prefer to manually mount components to the board surface, but this usually takes more time than SMT.Interestingly, SMT does not support all components. If the item you choose is not a standard size or otherwise, you may have to install the feature manually. This is why companies often use a combination of the above methods.

3.2. pcb design and manufacturing --Soldering

When welding is required, manufacturers will employ one of the following methods: Reflow soldering - This technique is ideal for permanently attaching components to a circuit board.

Wave - This welding is convenient when manually installing details. Iron - A large number of manufacturers rarely use this form of welding.

In the end, the manufacturer may only make a sample of the board to test its quality. After thorough testing and necessary modifications, mass production will begin.

kinhford Electronics is a professional PCB design company engaged in electronic product circuit board design (layout layout design), mainly undertake multi-layer, high-density PCB design and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier!