SMT is a surface assembly technology (surface mount technology), is the most popular technology and process in the electronic assembly industry, with high assembly density, small size of electronic products, light weight, high frequency characteristics and other advantages, so as to be widely used. SMT chip processing process is complex, involving many technical terms, many customers do not understand the meaning, the following SMT processing manufacturer -kinhford Electronics for everyone to share some SMT chip processing common technical terms.

SMT patch processing common professional terms

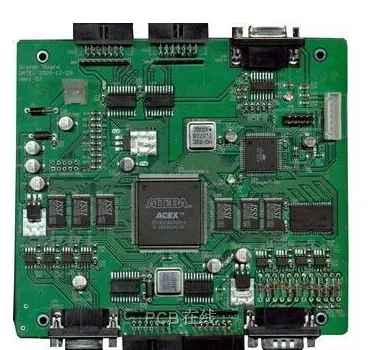

1, SMT processing surface mount components (SMA) : the use of surface mount technology to complete the printed board assembly.

2, reflow welding: by melting the solder paste pre-allocated to the PCB pad, to achieve the connection of surface mount components and PCB pad.

3, wave soldering: the melted solder, through the special equipment spray into the design requirements of the solder crest, so that the PCB pre-equipped with electronic components through the solder crest, to achieve the connection between the element and the PCB pad.

4, fine spacing: less than 0.5mm pin spacing.

5. Pin coplanarity: refers to the vertical height deviation of the pin of the surface mount component, that is, the vertical distance between the plane formed by the highest foot of the pin and the lowest foot of the pin. Its value is generally less than 0.1mm.

6, solder paste: By the powder solder alloy, flux and some of the viscous effect and other additives mixed into a certain viscosity and good thixotropy of the solder paste.

7, curing: under certain temperature and time conditions, heating the patch adhesive mounted with the components to make the components and PCB board temporarily fixed together.

8. Patch glue or red glue: a colloid with a certain initial viscosity and shape before curing, and a sufficient bonding strength after curing.

9, dispensing: surface mounting, the process of applying the patch glue to the PCB.

10, dispensing machine: can complete the dispensing operation of the equipment.

11, Mounting: The operation of picking up surface-mounted components from the feeder and placing them in the specified position of the PCB.

12, SMT feeding belt: used in the chip processing process of the feeder plate and plate connection, can not stop the operation connection, a lot of time and raw material costs.

13, SMT machine: special process equipment to complete the function of surface mounting components.

14, hot air reflow welding: with forced circulation of hot gas flow for heating reflow welding.

15, patch inspection: when or after the patch is completed, the quality inspection is carried out for whether there is any missing paste, dislocation, mispaste, component damage, etc.

16, Steel mesh printing: The printing process of using stainless steel leakage plate to print solder paste to PCB solder pad.

17, automatic steel mesh cleaning paper: installed on the printing press for automatic cleaning of excess solder paste in the process of steel mesh printing

18, printing machine: in SMT, special equipment for steel screen printing.

19. Post-furnace inspection: Quality inspection of PCBA welded or cured by reflow furnace after the patch is completed. a

20, pre-furnace inspection: after the completion of the patch in the reflow furnace welding or curing before the patch quality inspection.

21, repair: in order to remove the local defects of PCBA repair process.

22. Repair workbench: special equipment that can repair PCBA with quality defects.

kingford has its own SMT processing plant, which can provide SMT processing services for 0201 components in the smallest package. The SMT plant is equipped with 3 Fuji high-speed SMT lines, 2 DIP plug-in production lines, equipped with AOI optical detector, automatic solder paste printing machine, semi-automatic solder paste printing machine, lead-free wave soldering, lead wave soldering, upper and lower 8 temperature zone reflow welding, PCBA functional test frame, aging, board loading machine, cleaning tools, etc., at the same time, a professional research and development laboratory is set up. Five professional engineers cooperate with customers to perform general functional testing, test point testing, as well as channel, noise, waveform, drop and temperature testing.