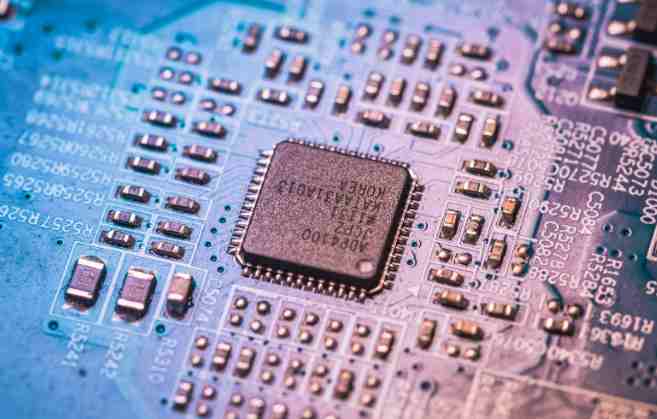

The development level of printed led circuit boards can reflect the development speed and technical level of the electronics industry in a country or region to a certain extent.

Printed led circuit boards are closely related to the continuous development of electronic products, and are important electronic components with multi-functional and integrated characteristics. It is a substrate for assembling electronic parts, and its main function is to make a variety of electronic components form a predetermined circuit connection, which plays the role of relay transmission, and is a key interconnection part of electronic products. The manufacturing quality of printed led circuit boards not only directly affects the reliability of electronic products, but also affects the overall competitiveness of products. Therefore, the printed led circuit board is known as the "mother of electronic system products", and its development level can reflect the development speed and technical level of a country or region's electronics industry to a certain extent.

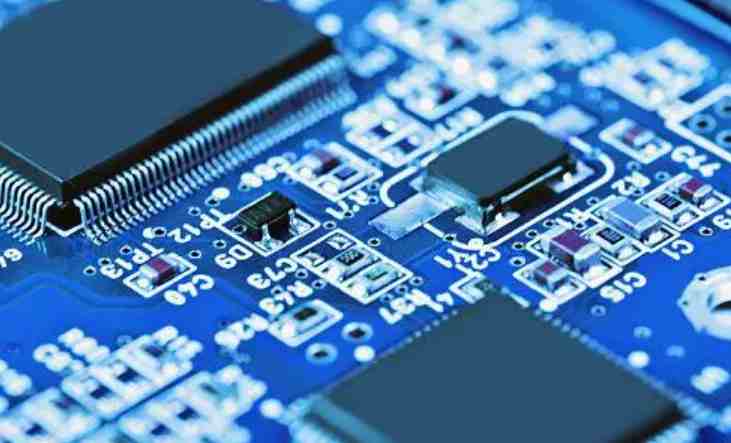

At present, the global PCB industry output value accounts for more than 1/4 of the total output value of the electronic components industry, which is the largest proportion of the industry in the various electronic components industry, and is also the most active industry in the contemporary electronic components industry. Due to the improvement of accuracy and complexity, the proportion of its value in the cost of the whole machine has increased, and it is the main pillar of the development of the electronic components industry.

The PCB industry does not belong to the electroplating industry

In the dozens of processes of the printed led circuit board manufacturing process, there is an electroplating process, and the industry can not be regarded as an electroplating industry.

In order to accelerate the development of China's electronic information industry, while China's printed led circuit board national brand enterprises strive to forge ahead, strive to achieve in the industrial scale, technology and the world's first-class enterprises keep pace, but encountered a development dilemma. Some departments of individual governments and banks do not know much about the industry, and mistakenly regard the industry as a heavy pollution industry, especially heavy metal pollution industry, and they are banned, mainly in two aspects: one is to drive the industry out of a certain area, and the other is that the bank believes that the risk is large and refuses to lend.

According to the convention, the supporting production chain of the product is best within 200 kilometers. For a region, if the local printed led circuit board industry all moved away, then the manufacturing of electronic information products will certainly migrate, is bound to have a great impact on the local economic development. Printed led circuit board industry is a high-investment, high-return industry, the simplest production line needs tens of millions of yuan of investment, and HDI production line needs hundreds of millions of yuan. Without the support of banks, the domestic printed led circuit board industry will shrink, which leads to the printed led circuit board used in China's electronic information products and return to the situation of relying on foreign enterprises.

In the dozens of processes of printed led circuit board manufacturing, there is an plating process, but the industry can not be regarded as the plating industry in the metal manufacturing industry. The plating of printed led circuit board manufacturing is a process in a continuous production line, and it is not possible to take this part out as a separate production enterprise. If the parameters of the production line are controlled accurately, the pollution generated can be minimized. Compared with electroplating enterprises with parts as production characteristics, electroplating in printed led circuit board manufacturing is local electroplating on the printed circuit plate, not only the types of electroplating are less, but also the amount of water generated is much smaller. As far as heavy metal pollution is concerned, the wastewater discharged in the manufacturing of printed led circuit boards is mainly copper, and there is a very small amount of nickel, according to the existing treatment technology, the two metals in the wastewater can eventually form metal mud and become raw materials for the smelter, so the printed led circuit board industry as a heavy metal pollution industry is not based on scientific evidence, is one-sided association.

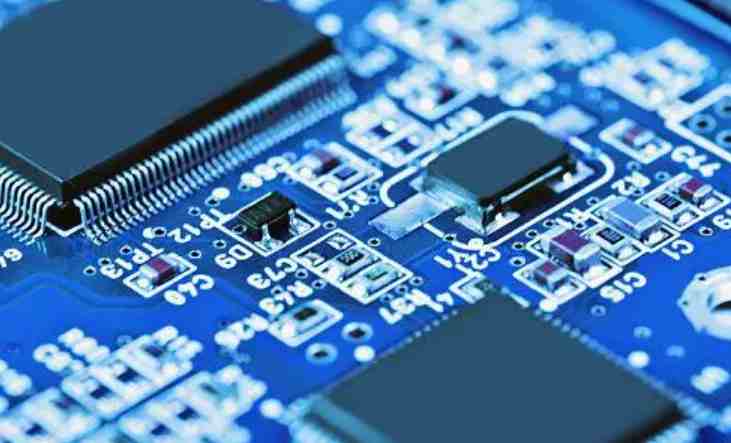

Printed board production will be more energy efficient and environmentally friendly

With the development of the production of printed led circuit boards in the direction of high precision and high density, the production of printed boards is more energy saving, emission reduction and environmental protection.

With the gradual requirement of light, thin and small electronic products, the production of printed led circuit boards is developing in the direction of high precision and high density, and the development of technology such as embedded discrete device technology, fully printed electronic technology using mathematical inkjet printing, and high heat dissipation metal-based printing plate makes the production of printed boards more energy saving and emission reduction and more environmental protection.

With the strong support of the state, China's printed led circuit board industry will overcome many difficulties, bigger and stronger, many enterprises will grow into world-class enterprises.