Why should an SMT factory use AOI inspection?

In modern production lines, in order to ensure product quality and production efficiency, many enterprises use a variety of testing equipment. In SMT processing (SMT is surface mount technology), the use of AOI (automatic optical inspection) inspection equipment is a very important link. So, why do SMT factories use AOI inspection?

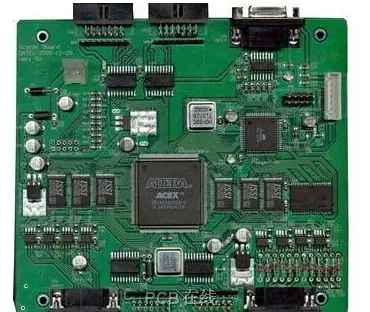

First of all, let's understand what SMT processing is. SMT processing is an abbreviation of surface mount technology, which refers to an electronic product assembly technology that attaches components directly to the printed circuit board. It has the advantages of small size, easy integration and high production efficiency, so it has been widely used in the electronics manufacturing industry.

In the process of SMT processing, the installation and welding of components is a very critical link. In this link, there are often problems such as inaccurate placement of components, short circuit, and poor welding. These problems will not only affect the quality of the product, but also have a negative impact on production efficiency. In order to avoid these problems as much as possible, SMT processing plants use AOI testing equipment for testing.

So, what is AOI inspection equipment? AOI inspection equipment is an automated equipment that detects component placement and welding quality through high-resolution image enhancement. It can simulate human eyes to analyze and recognize images, and identify defects through image processing algorithms. Compared with the traditional manual inspection, AOI inspection equipment has the advantages of high accuracy, fast detection speed, saving manpower and material resources. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

Below, let's take a look at the main roles of AOI detection equipment in SMT processing. First, it can identify the correct location of components. By detecting the pins of the components, the automation equipment can determine whether the components are correctly installed on the circuit board. If there is a problem, such as a pin float, other components blocked, then the automation device will alarm, notifying the staff to adjust and repair.

Secondly, AOI inspection equipment can also detect whether the welding is good. In SMT processing, welding is a link that is prone to problems, if there are poor ball connection, short circuit and other problems, it will lead to the circuit board can not work normally. Through the high-resolution image analysis technology of AOI inspection equipment, you can clearly see the welding situation of each spot, determine whether the welding quality is good, and if there is a problem, it will issue an alarm in time.

Finally, the AOI inspection equipment can also detect defects in the circuit board. In production, there may be some circuit board defects, such as large area solder joint defects, breakdown, break, etc. AOI inspection equipment can effectively identify these defects by performing high-resolution analysis of the board image, avoiding the situation where undiscovered defects lead to quality problems.

To sum up, the importance of AOI testing in SMT processing is self-evident. It can ensure the correct placement and welding quality of components, timely detection of circuit board defects, and avoid affecting product quality and production efficiency. With the improvement and popularization of automatic testing equipment, SMT processing plants will increasingly rely on AOI testing equipment.