SMT mounter pressure/position/image/area sensor role

SMT mounter pressure/position/image/area sensor role sensors are an important part of the entire machine, if each sensor does not assist each other, it can only depend on the system can not be assembled and produced, then what sensors do SMT mounters have? What does each sensor do? Let's take a look at the following.

1. Pressure sensor: mainly responsible for detecting and sensing air pressure. When we use SMT components, cylinders and vacuum generators have certain requirements for air pressure. Pressure sensors play an important role here. When the detection pressure is low, it will immediately alert the staff to detect the pressure.

2. Position sensor: It can not only provide the position of the PCB board for the SMT mounter system, but also detect the number and movement of PCB components in real time, and provide help for our system assembly, so there are strict requirements for job information.

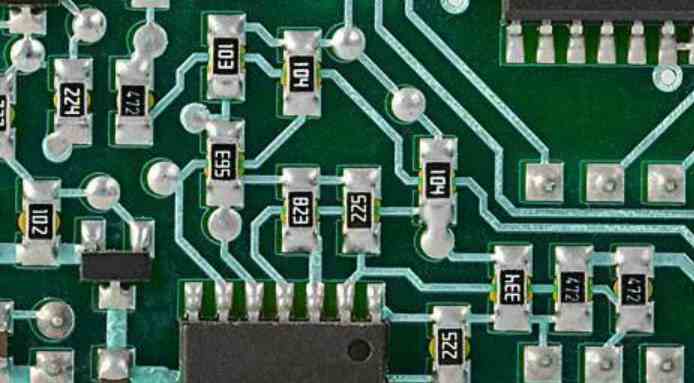

3. Image sensor: The sensor can provide real-time working status of the SMT assembler, collect various image signals required at this time, including the position of the PCB board, the size and model of the installed components, and then analyze and process the assembly task through the common seating system.

4. Area sensor: mainly used for real-time detection of security problems. When we use the SMT mounter, for safety work. An area sensor is usually installed in each moving area to continue to detect the content information of the workspace

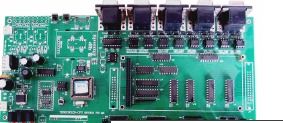

SMT mounters are a common method that we usually paste on an electronic device that has a lot of parts inside it together to complete our production work, do you know what the main parts are? Don't worry. I'll explain it carefully.

1: A fixed head mounting head is a sensor that can help the mounting machine to carry out various work and production in the production of the mounting machine. It may be very good to help our SMT machines to increase assembly efficiency. When it comes to frame design, the mounting head is an important factor in the operation of the mounting machine. SMT installers want to increase accuracy and speed depending on the mounting head design. Therefore, when the SMT assembly machine is assembled quickly and accurately, attention must be paid to the design and use of the assembly head. https://www.kingfordpcb.com/yuan.php?time=1686077467

https://www.kingfordpcb.com/yuan.php?time=1686077467

2: spout

The function of the nozzle is to absorb and install the component. For different types of mouthpieces, we also need different types of mouthpieces. When the nozzle moves, a negative vacuum pressure is created inside the nozzle. When the nozzle contacts the assembly components, the components are firmly absorbed by negative pressure under vacuum and then released to the specified position through the positioning of the system. This series of actions is the function of the nozzle to help lay the machine. The nozzle is the most easily damaged part of the entire SMT system, so it must be replaced in time.

3: Solenoid valve

The electric solenoid valve is divided into pneumatic solenoid valve and electric solenoid valve, which is an important part of our SMT SMT machine. The function of the solenoid valve is to interact with the system and manage other instruments by moving, picking, releasing and other operations. The driving force of the solenoid valve is very small, so the solenoid valve can be directly driven by the circuit controller we usually use.