What is the defect detection strategy of PCB bare board?

PCBS play such a critical role in electronic devices that a one-hour robust defect detection strategy is required to ensure that any costly errors are avoided. This is true for both bare PCB boards and fully assembled circuit boards. Let's examine both aspects in more detail.

At its core, PCB manufacturing is a very precise science with little margin for error. Therefore, a major requirement is to verify the electrical continuity of the board. There are two main ways to test these primitive plates. These include:

Needle bed test flying needle test system needle bed test https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

This way of working is to build test fixtures for specific PCB designs. The jig contains a number of spring loaded test pins. In fact, this is where the test names come in. Press PCBS onto test pins and then check their conductivity. The test is known for its short test time.

Flying needle test originated from bare plate test, involving short circuit, open circuit and other tests. The main parameter of the test is the resistance between the points. However, these tests have been developed to measure capacitance and inductance. In fact, this is what makes them effective for testing not only bare boards but also PCB components. Reasons for the widespread use of this test for defect detection include:

They have fewer accessibility problems than ICT testers.

Because the movement of the probe is controlled by software, the changes are easy to implement. They provide better test coverage than ICT tests.

Defect detection tests can also benefit from the first article tests. Essentially, this involves testing the first to build what is called a "gold" unit. If the first article tests show no defects, the entire production run is considered to have passed the connectivity tests. Another important purcircuit board pose of the first article is to establish a record of the paperboard production process. Once the POR has been created and replicated, you can rest assured that each board functions similarly.

cc

These steps ensure that any defects can be identified in the first article phase itself, and then no mass production is carried out without classification. If any errors are found, corrective action can be taken. At this stage, you can also identify any changes that may be needed in your design.

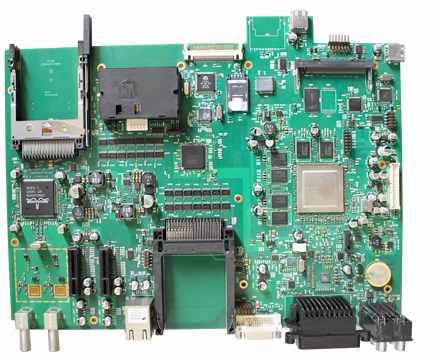

If the PCB board is exposed, then this is relevant or manual as well as automatic inspection techniques. In short, the role of the automated optical inspection is to scan the board and then compare its image to that of the first product production board. Therefore, any errors can be easily flagged. In addition, manual checks are performed by trained technicians to identify any errors that may have been missed by the automated system after the bare board was manufactured.

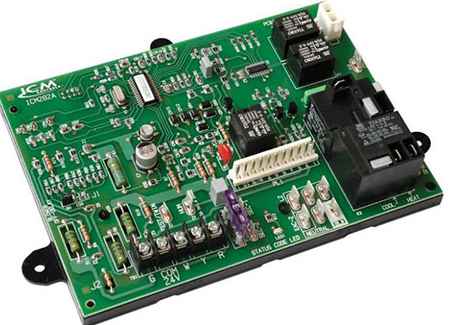

With so many checks and balances, experienced bare board manufacturers can significantly reduce the likelihood of errors and defects on bare PCBS. The bare board can be used for the next step, including mounting the components on the board or what is commonly known as PCB assembly.

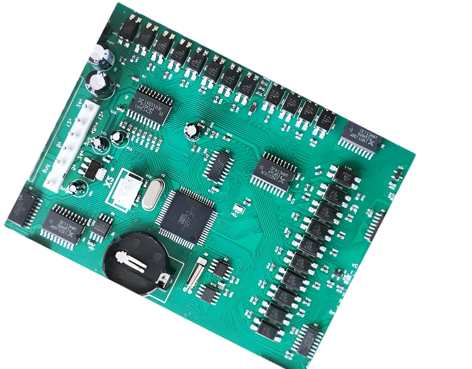

Although we will focus on PCB bare board manufacturing and determining defect testing strategies for bare boards, it is prudent to briefly look at some defect testing strategies for PCB components. Some of them include:

Eye check Automatic check flying needle test online test functional test

Importantly, it is also important to ensure that PCB designs are optimized for manufacturability. In this case, you may encounter many problems, such as solder defects, broken tombstones. A PCB manufacturer with a good track record can help you go a long way with robust design principles and also stick to DFM rules and processes.