Typically, flexible PCB assembly processes are used in the modern world and technology for a variety of reasons. Traditionally, it is used for changing wire controls and Settings. It is well known that flexible PCB assembly processes have been evolving since World War II. As the days passed, this became the reputation of the present.

The installation and use of flexible PCB assembly process is very simple and has advantages. It's perfect for simple applications that can stick to multiple perfect variations. This is used to solve and process any given board task and work.

So, with this versatility, most people want to know more about it. Therefore, today we will discuss a complete guide to the assembly process of flexible PCBS.

smt pcb factory

What does flexible printed circuit mean?

Flexible printed circuits are notoriously light. It is a circuit that can easily be used in tight Spaces or well-crafted Spaces. Also, these are more areas where flexible PCB components can be bent. Flexible circuits can allow for other differences or advantages.

Flexible PCB assembly circuit boards do make up a variety of things. It has a strip of conductive metal usually made of copper. It is then insulated with the help of a dielectric mask or material.

The circuit board is fully functional. Its main function is to execute signals encoded as electricity. They provide good and stable mechanical bending, allowing the user to choose connectors that are considered smaller. These connectors are good at shielding EMI noise from frequent radiation.

PCB is the main component substrate and non-conductive plate. It is used to connect various electronic components to make circuits according to electrical rules.

What are the types of flexible PCB circuits?

There are several types of flexible PCB assembly circuits. However, some of the major and basic types are described in more detail below.

One side flexible PCB circuit

The first basic type of flexible PCB circuit is single-sided. These circuits are known to be single-sided because they have only one metal layer. The metal layer exists on one side of the layer and is called the dielectric.

Double-sided flexible PCB circuit

Another type of flexible PCB assembly circuit is the double-sided circuit. Unlike single-sided flexible PCB circuits, this circuit has metal layers on both sides. These layers exist essentially on either side of the dielectric layer.

Multilayer flexible PCB circuit

Next is the multilayer flexible PCB circuit. In double-sided flexible PCB circuits, the metal layers are often connected by metallizing holes.

Similar holes are found in this type of flexible PCB circuit. They have various copper layers that are not adjacent to each other. Instead, they are separate. In addition, they are layered by dielectric metals.

Rigid flexible bonded PCB circuit

A rigid-flexible PCB circuit is a type that has components belonging to both types. One is hard and the other is flexible. This combination leads to the formation of another circuit called a hybrid circuit board.

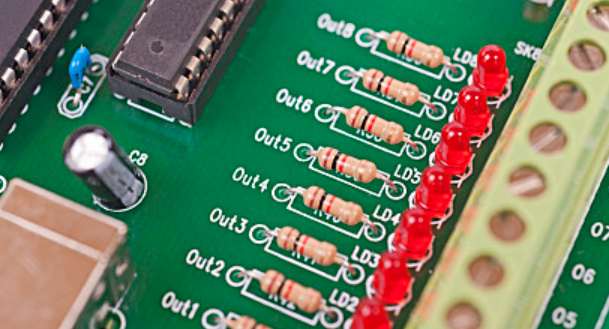

Multilayer flexible PCB

What are the benefits of the flexible PCB assembly process?

If we generally compare the common rigid board and wiring system, we can say that flexible PCB has many benefits. Advantages include a very precise wiring system and mechanical connectors. Or it can be used to complete designs and provide high density circuits.

It is also used to select a wide range of operating temperatures. Or provide better quality for robust signals. It also allows for improvements in control size and other reliability factors.

Automated production also helps eliminate human error. Flexible PCB circuits are designed to route only circuits added or designed to them.

A lot of labor is used in the process of printing PCB. The flexible PCB assembly process is quite affordable in terms of money and time.

Flexible circuit boards are available in custom forms and shapes. All of this is possible because the flexibility of the design process is not limited by the existence of two dimensions. This flexibility also allows for the installation and addition of third party sources. This third face is usually used to join two or more two planes.

The functionality of flexible circuit boards has also been shown to improve various other aspects. Like, better and increased air flow. Dissipation of heat and high density population is accomplished by using the simple geometry of the circuit.