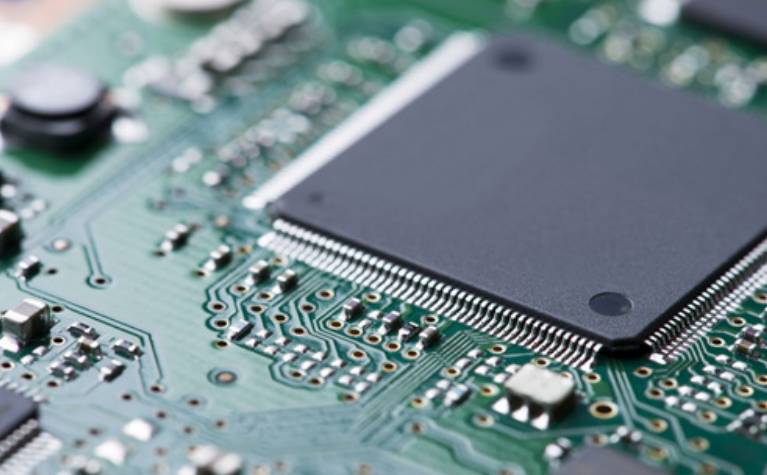

With the development of The Times and the progress of science and technology, now driverless, smart home, smart wear and other black technologies have been emerging around us, and the core components of these products include circuit boards. At present, the PCB circuit board products on the market are mainly divided into three kinds from the material categories: ordinary substrate, metal substrate and ceramic substrate.

1. Classification of metal substrate:

There are three main types of metal substrate: aluminum substrate, copper substrate, iron substrate. Iron substrate is rarely used in the market, here the focus of analysis is aluminum substrate, copper substrate.

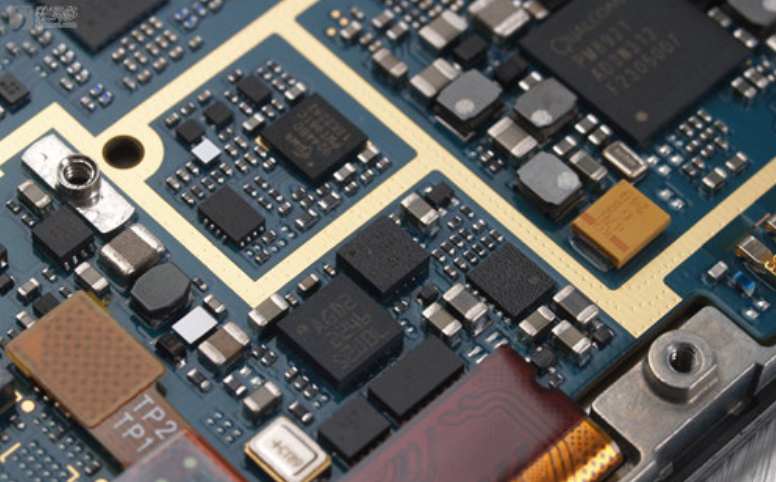

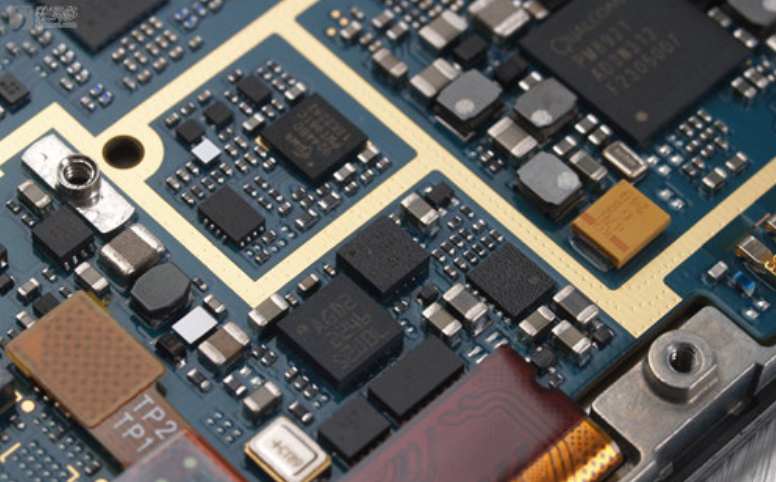

Aluminum substrate is a kind of unique metal-base copper-coated plate, which has good thermal conductivity, electrical insulation and machining properties. Aluminum substrate is the most used metal substrate, aluminum substrate has 10 times higher thermal conductivity than epoxy resin substrate. Aluminum substrate is divided into flexible aluminum substrate, mixed aluminum substrate, multilayer aluminum substrate, through hole aluminum substrate, etc.

Copper substrate is one of the most expensive metal substrate, thermal conductivity is many times better than aluminum substrate and iron substrate, its circuit layer requires a great current carrying capacity, so should use thicker copper foil, thickness generally 35μm~280μm; Copper substrate is divided into gold plating copper substrate, silver plated copper substrate, tin spray copper substrate, copper oxide substrate, etc.

Two, the advantages of metal substrate:

Metal substrate began to be used in the 1960s, the 1980s and 1990s in the world is widely used, the estimated global annual output value of metal base printing is about two billion dollars. What makes metal printed boards so popular?

1. Thermal expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. The metal substrate can effectively solve the problem of heat dissipation, so that the problem of thermal expansion and contraction of different substances on the circuit board can be alleviated, and the durability and reliability of the whole machine and electronic equipment can be improved.

2, heat dissipation

At present, many double panel, multi - layer plate high density, high power, heat distribution is difficult. Conventional circuit board substrates, such as FR4 and CEM3, are bad conductors of heat, interlayer insulation, heat dissipation does not go out, resulting in high temperature failure of electronic components, and metal-based printed boards can solve this problem of heat dissipation.

3. Dimensional stability

The metal substrate size is obviously much more stable than that of the insulating material. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

4. A wide range of applications

Iron substrate, with shielding effect, can replace brittle ceramic substrate, replace radiator and other components, improve heat resistance and physical properties of products, reduce production costs and labor.

Aluminum substrate, copper substrate is widely used in various fields.

Aluminum substrate has a wide range of applications, such as audio equipment input, output amplifier, balance amplifier; Computer CPU board, floppy disk drive, power supply device; Automobile electronic regulator, igniter, power controller; Lamps, lighting, LED lights, etc., use aluminum substrate.

Copper substrate is one of the more expensive metal substrate; Compared with aluminum substrate, because the material is relatively special, the heat dissipation is relatively good, so the price will be relatively more expensive, mainly suitable for high frequency circuit board and high and low temperature change area and precision communication equipment heat dissipation and building decoration industry.