Industrial PCB circuit boards often need maintenance, then, industrial PCB circuit board maintenance are what rules?

First, maintenance to understand the vulnerable parts on the circuit board

l, the design is not reasonable place is the most prone to failure

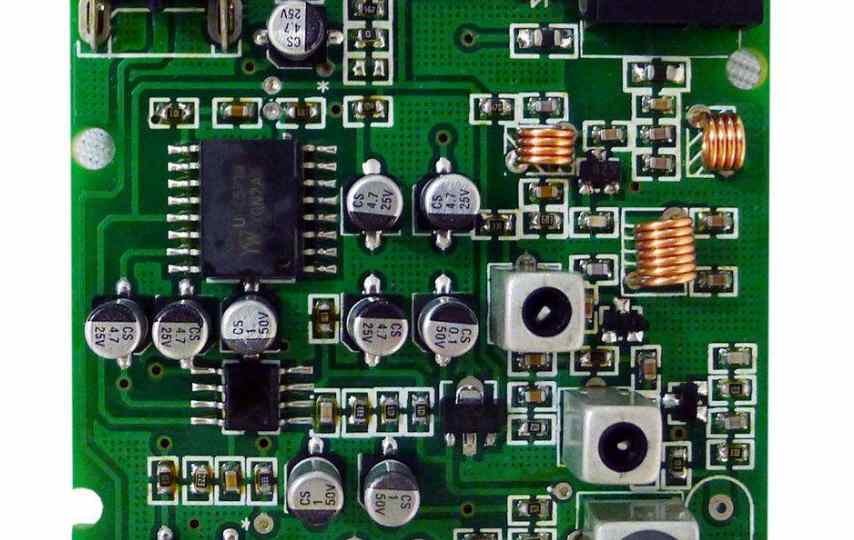

Industrial circuit board in the end where the design is not reasonable? First of all, the heat dissipation problem, a lot of circuit board damage is because of the heat dissipation design is not good; The second is printed board copper foil line, poor quality circuit board power supply line copper foil is very thin, easy to burn due to the current, so that the motherboard can not work.

2, frequently used places prone to failure

For example, industrial circuit board drive motor, rotating shaft, switching power switch tube, operation panel commonly used keys.

3. Components with heavy load, large power and high working voltage are the most prone to failure

Industrial circuit board power supply, drive circuit, power control devices, operational amplifier is the most easily damaged, these components are generally close to the heat sink, if the protection measures do not do enough, heat dissipation is not good, it is easy to become the first "victim".

4, the protection circuit is the most easily damaged

Valuable chips or components on the circuit board are protected, equipment once abnormal, the first sacrifice is these protective circuits. These protective devices should be instantly recognizable during maintenance.

5. The interface and line of the inline seat and connector are easy to contact poorly or break the line

For example, the board and slot contact is bad, the cable is broken when the internal through, the wire plug and terminal contact is not good, components welding, etc.

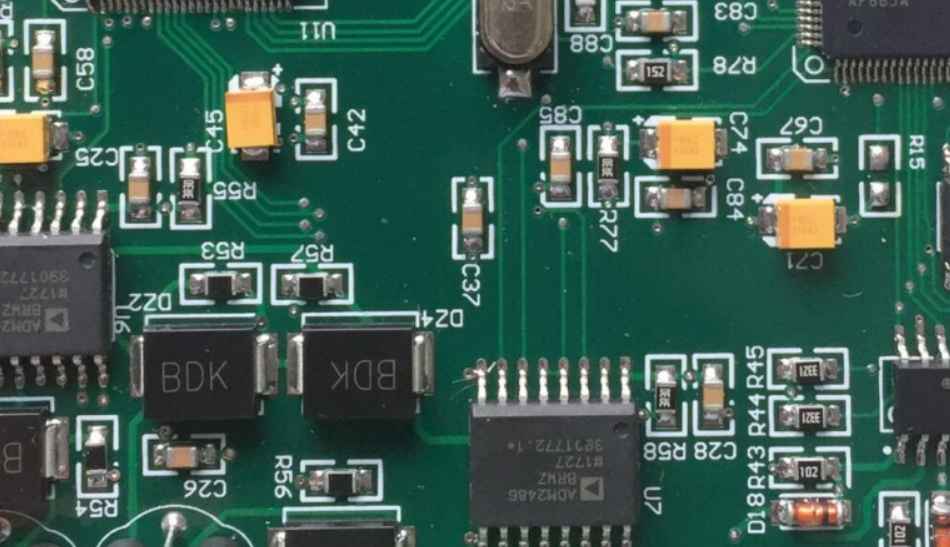

Two, industrial circuit board commonly used components damage characteristics and detection

Industrial circuit board damage is usually a component damage, may be a chip, a capacitor, or even a small resistor, the repair process is to find the damaged component to replace.

1. Small resistance and large capacity of electricity are easy to break

Small resistance is often used to limit the current on the power supply line, that is, to play the role of fuse, if the current is too large, the first will be burned off. In addition, many ground capacitors are used to filter the power supply line, and the head and capacity are generally large. If the voltage or current is unstable, it will breakdown the capacitance and lead to leakage.

2. Fault characteristics and maintenance of capacitor damage

The failure caused by capacitor damage is the highest in electronic equipment, especially the electrolytic capacitor damage is the most common. Capacitor damage is manifested as: 1. Capacity becomes smaller; 2. Complete loss of capacity; 3. Electric leakage; 4. Short circuit.

3, operational amplifier is good or bad discrimination method

No matter what type of amplifier, there is a feedback resistance Rf, we can check this feedback resistance from the circuit during maintenance, use a multimeter to check the resistance between the output and the reverse input. If it is too large, such as more than a few MΩ, then we can probably be sure that the device is used as a comparator; If the resistance value is smaller 0Ω to dozens of kΩ, then check whether there is no resistance connected between the output and the reverse input end, if there is a must be used for amplifier. According to the principle of virtual short amplifier, that is, if the operational amplifier is working properly, its co-input and the opposite input voltage must be equal!

Three, maintenance should be "chest frame"

How to repair industrial equipment in the absence of PCB board related data?

You can draw inferences from one example to the next. For example, switching power supply, always inseparable from the oscillation circuit, switching tube, switching transformer, check whether the circuit vibration, capacitor damage, each transistor, diode damage, etc. In addition, maintenance should pay attention to the maintenance order to find the shortest path to solve the problem, avoid rambling, maintenance is not, reverse fault expansion.