Before we understand what SMT is, we need to clarify the difference between SMD and SMT. Sometimes we hear people speak of SMT, and sometimes we hear people speak of SMD. The two terms can be mixed sometimes, but basically there are some differences:

SMD: Surface Mount Device. Surface mount parts. So the term refers to parts, generally referring to those electronic parts that can be made using SMT process or technology.

SMT: Surface Mount Technology, surface mount technology. So the term refers to a technology where electronic parts are welded to the surface of a circuit board.

A car can be compared to a car. A car is a complete product with many parts (tires, doors...). These are the parts of the car; Driving is a kind of technology. To say that you can drive means that you know how to drive. Technology usually needs to be learned and operated for a long time before practice becomes perfect.

What does SMT mean?

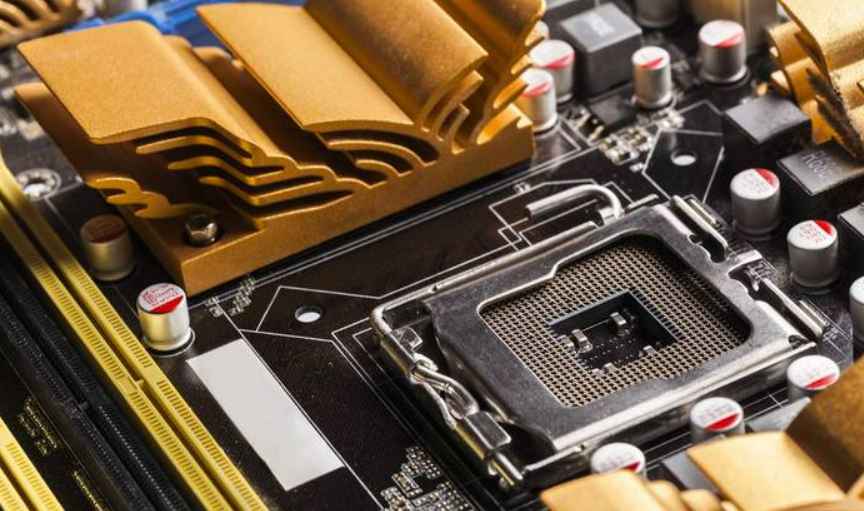

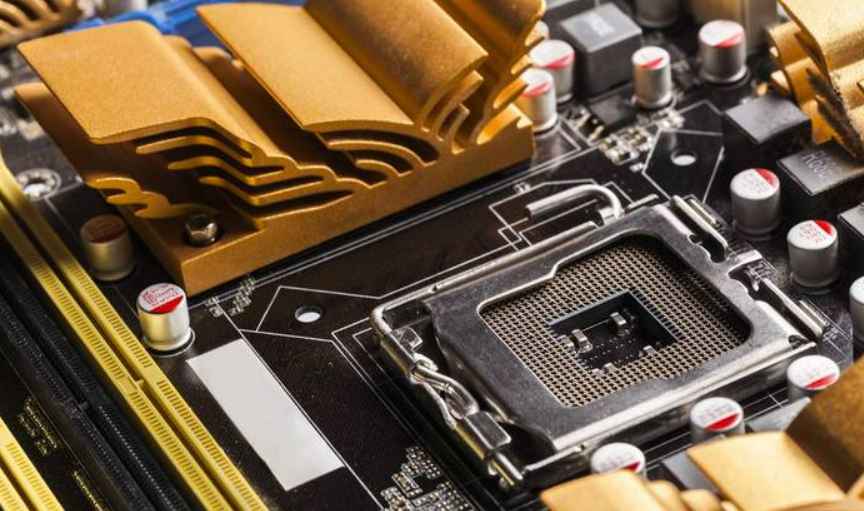

Interpreted literally, it is a technology that welds electronic parts onto the surface of a Circuit Board (PCB, Printed Circuit Board), which is different from the earlier through-hole parts. Using the "wave welding" technology, this SMT technology can greatly reduce the size of the electronic product, achieving the purpose of lighter, thinner, shorter, and smaller. Here we can temporarily compare the traditional through-hole plug-in to the previous vacuum tube TV, and SMT technology can be compared to LCD TV.

Early electronic parts only had the technology of through-hole welding when they came out, so electronic parts had to have extra welding feet designed to pass through the PCB circuit board, so as to achieve the purpose of welding the parts on the circuit board. However, the welding feet of such through-hole parts had its minimum size limitation, otherwise the welding feet would be easily broken, or caused by external force broken because the users accidentally fell to the ground. Therefore, the through hole parts can be 5mmx5mm, which is already very small. However, the smallest size of the current SMD parts can be 01005 (0.4mmx0.2mm), or even smaller. This is why the original black gold phone was as big as a brick and could only make phone calls. Today's smartphones are less than one-tenth the size of the black gold, but they have more features.

What kind of technology does SMT use to weld electronic parts to circuit boards? The answer should be Solder Paste. As long as you print solder paste on the welding pad (pad) of the parts to be welded, then put the electronic parts on it. Put the solder foot just where the solder paste is, and let the solder paste pass through the high temperature back to the welding furnace. The reflow will melt the solder paste, which will turn into a liquid. The liquid solder paste will cover the solder base of the electronic parts. When the solder paste becomes solid again after the temperature has cooled, the electronic parts will be welded to the PCB board.

What are the advantages and benefits of SMT technology for electronic products?

1. Electronic products can be designed to be thinner and shorter. Parts become smaller, the circuit board area will also be smaller than the previous through hole parts.

2, can design more high-end products. Because SMDS are small and thin, electronics can be used in more zero fields. Such as microrobots, faster cpus (central processing units), and more suitable for portable electronics.

3, suitable for mass production. SMT technology eliminates most manual plug-in work and uses machines to place electronic parts, so it is more suitable for mass production of high-quality products and has a more stable manufacturing process than through-hole plug-ins.

4, the production cost is reduced, basically reduced manpower and hours. Because through hole parts rely on manual installation, while SMT is replaced by machine installation.