One, how to maintain no drawing circuit board?

1, to "chest map"

Understand the principles of some typical circuits thoroughly and know them by heart. Drawings are dead, the mind is alive, can be analogy, can be reasoning, can draw inferences, all through. For example, switching power supply is always inseparable from oscillating circuit, switching tube and switching transformer. During inspection, it is necessary to check whether the circuit is vibrating, whether the capacitor is damaged, and whether the triode and diode are damaged. No matter what switching power supply is encountered, the operation is almost the same. For example, single-chip system, including crystal oscillator, three buses (address line, data line, control line), input and output interface chip, maintenance is inseparable from these ranges; Another example is the analog circuit composed of various operational amplifiers, if it changes, in the "virtual short" and "virtual break" on the basis of reasoning, can also have a head have a thread, orderly analysis, make a clear. After practicing good skills of analysis and reasoning, even if you encounter a device you have never seen before, you just need to understand it in principle.

2. Pay attention to the maintenance sequence

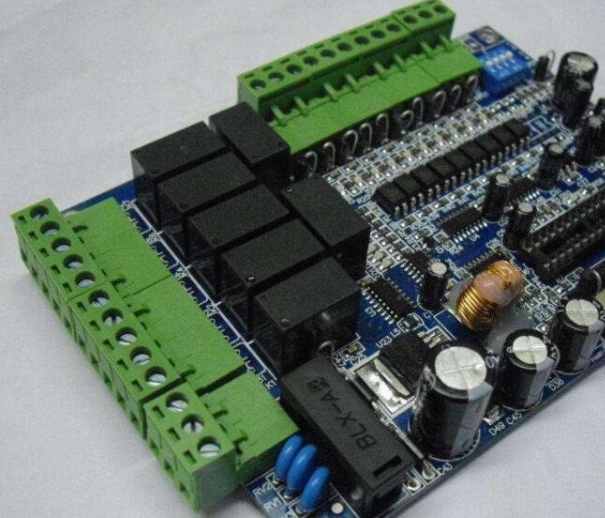

Pay attention to the maintenance order to find the shortest path to solve the problem, to avoid disorderly poke and dismantle, maintenance is not, resulting in fault expansion. Maintenance is like a doctor to see a doctor, but also pay attention to a "look, hear and ask." "Look" is to check the appearance of the fault board, see there are no traces of obvious damage, there are no components burning black, burst,PCB circuit board is not caused by corrosion, leakage, capacitor leakage, the top is not bulging; Sniff for the smell of burning and where it is coming from; "Ask" is very important, to ask the party in detail, equipment failure at the time of the situation, from the situation reasoning possible fault parts or components; "Cut" is to use certain testing instruments and means, divided into power and no power two cases, check the circuit parts or components of the resistance value, voltage, waveform, will be good or bad circuit board comparison test, observe the difference in parameters, etc.

In fact, there are a lot of failures you don't even use the multimeter on the solution, the circuit diagram naturally free.

3, to be good at the total section rule

Generally, after a certain accumulation of maintenance experience, we should be good at analyzing the causes of each component damage. Is it improper operation? Lack of maintenance? Bad design? Component quality is poor? Natural aging? With this analysis, the next time you encounter a similar fault, even if it is not the same printed circuit board, you will have some certainty.

4. Be good at finding information

Since the advent of the Internet, finding information has become very easy. Do not understand the equipment principle, do not understand the circuit principle, almost can be found from the Internet, what IC data can be found from the Internet.

5, to have the necessary testing equipment

If you make maintenance your career, then a certain amount of equipment investment is necessary. Electric soldering iron, multimeter, commonly used disassembly tools, the brand is not too bad. If possible, then get a 100M double trace oscilloscope, and if possible, set up an online maintenance tester.

Two, industrial control PCB board capacitor damage fault characteristics and maintenance

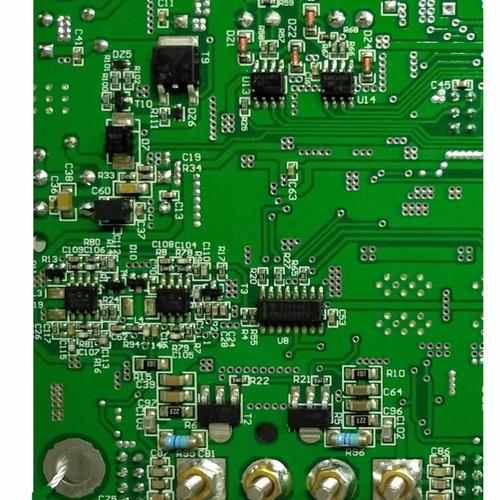

The failure caused by capacitor damage is the highest in electronic equipment, especially the electrolytic capacitor damage is the most common.

Capacitor damage is manifested as: 1. Capacity becomes smaller; 2. 2. Complete loss of capacity; 3. Electric leakage; 4. Short circuit.

The function of capacitor in the circuit is different, and the fault caused by it has its own characteristics. In the industrial control circuit board, digital circuit accounts for the vast majority, capacitors are mostly used for power supply filtering, and less capacitors are used for signal coupling and oscillation circuit. If the electrolytic capacitor used in the switching power supply is damaged, the switching power supply may not vibrate, no voltage output; Or the output voltage filtering is not good, the circuit due to the voltage instability and logic chaos, as the machine working good or bad or can not open the machine, if the capacitor and in the digital circuit between the positive and negative terminals of the power supply, the fault performance is the same as above. This is especially obvious in the computer motherboard performance, many computers with a few years on sometimes can not open the machine, sometimes can boot phenomenon, open the case, often can see the electrolytic capacitor bulge phenomenon, if the capacitance is removed to measure the capacity, found to be much lower than the actual value.

The life of the capacitor is directly related to the ambient temperature. The higher the ambient temperature is, the shorter the life of the capacitor is. This rule applies not only to electrolytic capacitors, but also to other capacitors. Therefore, when looking for the fault capacitor, we should focus on checking the capacitor close to the heat source, such as the capacitor beside the heat sink and high-power components. The closer it is, the more likely it is to be damaged.

Some capacitors leak so badly that they even get hot when touched by fingers. This capacitor must be replaced.

In the maintenance of good or bad fault, excluding the possibility of poor contact, generally most of the capacitor damage caused by the fault. So in the event of such a failure, you can focus on checking the capacitor, replacing the capacitor is often surprising (of course, also pay attention to the quality of the capacitor, to choose a better brand, such as ruby, black gold just).