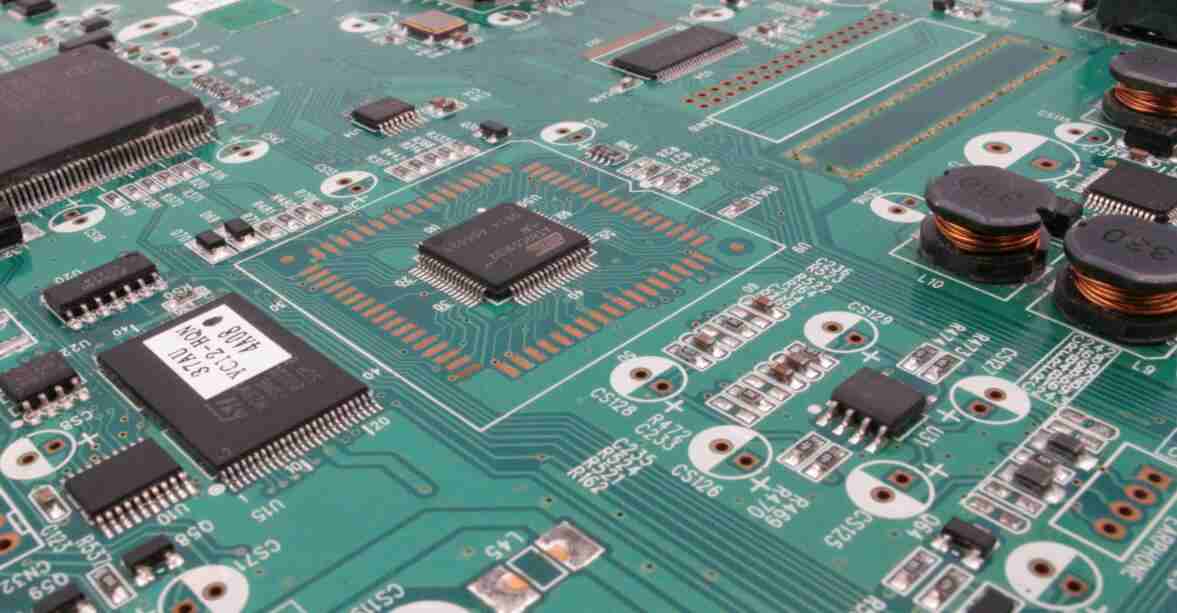

Electronic components and their scarcity have been in the news lately. As the production of electric vehicles and the consumption of related electronic components continues to expand, automotive suppliers are caught in a supply chain dilemma. Wafer-less semiconductor companies with insufficient capacity are also in the news as their delivery dates have been delayed to 2022. All this news, along with the shrinking life cycle of semiconductor devices, has left some electronics manufacturers short of supplies. In some cases, you can meet their shortage requirements by fetching the specified component from an existing component.

Getting electronic components from circuit boards allows you to reuse outdated, expensive, and long lead times. These components can be obtained from scrap dumps, discarded components, or by other means. Care must be taken to ensure that components can be reused in the manufacturing environment and to provide the greatest chance of having reliable components welded in place.

Removal of mechanical parts

The first step in recovering components from components that weld valuable electronic components is to remove the mechanical parts. This operation may include unscrewing the screws, removing the following components and larger components, such as the radiator, fan, and power supply.

Start the recycle operation

Once all mechanical subcomponents are removed from the board, the recovery operation can begin. The key is to understand all of the requirements of the end user, including the packaging of the recovered component, whether to remove the tri-proof paint, the MSL rating of the component, and many other requirements.

MSL rating

If the PCB board has been stored in the open or returned from the site, it is usually necessary to pre-bake the component prior to removal according to the MSL grade of the component removed. This will help ensure the long term reliability of the components being recovered.

coating

Not only the MSL rating of the component should be considered, but also whether the board has been coated, the component has been secured in place, or the component has been underfilled. The presence of filler material or tri-proof paint on and below the element to be removed is important because there are many peeling processes that are part of the removal operation. In some cases, this can lead to difficulties, including yield issues. It is important to determine the total area of paint removal at the beginning. For example, if you need to remove tri-proofing paint from the body of a component, this process may have the unintended consequence of removing part numbers, date codes, and other information from the package.

The adhesive and bottom fill material may soften during removal, and subsequent removal from the component body may take too much time to make component recovery economically unfeasible. In addition to the above requirements, the electrostatic discharge (ESD) sensitivity level of the component should be considered during the recovery process. Just because the parts are recycled doesn't mean they shouldn't be treated like "live" circuit boards. The component data sheet will inform the remover of the types of ESD precautions to be taken.

label

Another area of concern is labels on components or PCB circuit board. All recovery processes, including paint strippers, heating, cleaning agents and fluxes, interact with the circuit board of the component to be recovered. Component or circuit board labels may need to be covered with Kapton or liquid film to prevent the labels from disappearing during processing.

Other operations

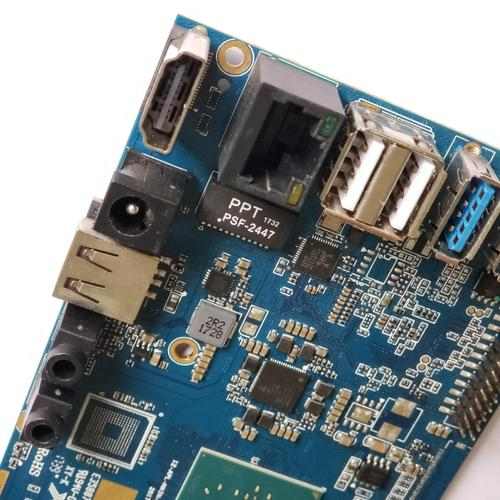

There are several operations to consider for the component itself. Small led elements (such as high pin count QFP) may need to have their leads straightened and formed coplanar when removed to meet JEDEC requirements in order to place them properly on a possible new printed circuit board. The solder ball needs to be reattached to the removed BGA or CSP by the replanting ball process to place it on the new component. The component data sheet will help determine the correct solder ball size. Appropriate solder alloys can be determined according to customer order details.

For component recovery, pay attention to the maximum temperature the component can withstand. This is important because of the need to select the correct dismantling process tools and temperature curves. The correct curve will ensure that the temperature limit that the component can withstand is maintained during the removal process.

Future use

One of the important criteria for determining the requirements for recycling components is to know how to place components on the next board. For example, if the component will be welded into place by hand, then the coplanality and residual solder amount of the component will be less than that of the component placed with an automated tool.

One of the final standards is the type of component packaging required. Components need to be placed in coil packages, tubes, or pallets in order to transport the recovered components to the manufacturing plant. It is recommended that components be labeled in some way to keep track of which components will go into a particular component.

identification

After taking these requirements into account, the process of recovering the electronic components from the circuit board will be completed smoothly.