Although the mature SMT technology brings more and more benefits to enterprises, but because of the increasing demand, there is a situation of short supply. In order to solve this problem, many electronic enterprises and even SMT processing manufacturers in the peak season, will choose smt external processing. So, what are the benefits of smt external processing? Why do more and more enterprises choose this way of processing? The following patch manufacturer would like to say what are the benefits of smt external processing and what are the related knowledge of the characteristics of flexible circuit board patches.

1. What are the characteristics of flexible circuit board patches

In the process of patch processing, there will be a lot of technical terms, for people in the industry, if they do not understand clearly, it will cause great obstacles to production. So, what is a flexible circuit board patch? What are its characteristics? Where does it apply? Below, Xiaobian and everyone together to discuss. What is a flexible circuit board patch? Flexible circuit board patch is in the production process, in order to prevent circuit board short circuit too much lead to low qualified rate or reduce drilling, calender, cutting and other processes lead to FPC board scrap process, this process, reliability is very high, and is the best flexible printed circuit board, advantages are very many, the use of a wide range.

What are the characteristics of flexible circuit board patch?

1, short assembly time According to professionals, flexible circuit board patch after all the circuit configuration, the time used is much less than other circuit board assembly methods. Not only that, but it also eliminates a lot of unnecessary wiring and connection work, making configuration faster and more efficient.

2. Small size Compared with PCB, flexible circuit board itself is small in size. As a result, the resulting PCB is much smaller and easier to carry.

3, light weight because the weight of the flexible circuit board is very light, so, after the processing of the flexible circuit board patch, its total weight is still very light. This is great for electronics and other demand industries.

4, ultra-thin flexible circuit board is very flexible, softness is also very high, even after the flexible circuit board patch, there is still a strong softness and operability, so that the operator will be more convenient in the operation process, the success rate will be higher. What are the flexible circuit board patch application industries?

1. Mobile phones

Mobile phones on the flexible circuit board patch demand is very large, according to the industry, because the flexible circuit board in the patch, can effectively reduce its weight and volume, thus can greatly save the product volume, make the mobile phone more compact. In this case, the battery, microphone, buttons into one, more convenient to use.

2, computer, liquid crystal display

Through the integrated circuit configuration of the flexible circuit board, so that the LCD, computer thinner, this is the modern computer, LCD more and more compact, more and more delicate one of the reasons.

3. CD Walkman

Although modern people with walkman has been very few, but the early production of walkman, is also the use of flexible circuit boards. Especially the three-dimensional assembly of flexible circuit boards and ultra-thin thickness, so that the huge CD can be carried around the walkman, by consumers love and praise. It is because of this, flexible circuit board patch technology can develop rapidly. Flexible circuit board patch is one of the modern indispensable technology, it is with this technology, to make our life more relaxed, more pleasant. With the continuous upgrade of flexible circuit board patch, there will be more and better products waiting for us to develop in the future.

2. What are the benefits of smt external processing

First, high reliability

Some enterprises feel that they will smt external processing, is to control the quality in the hands of others, good or bad is not subject to their own control. In fact, such concerns are not necessary, because modern SMT technology is very mature, as long as the funds are in place, you can obtain relatively advanced equipment and technology, so that the quality of both domestic production and external processing can be guaranteed. In addition, once smt is processed outside, the quality of products will be linked with the other factory. If the agreed standard is not reached, compensation will be required. Therefore, enterprises do not need to worry about the quality of products after external processing.

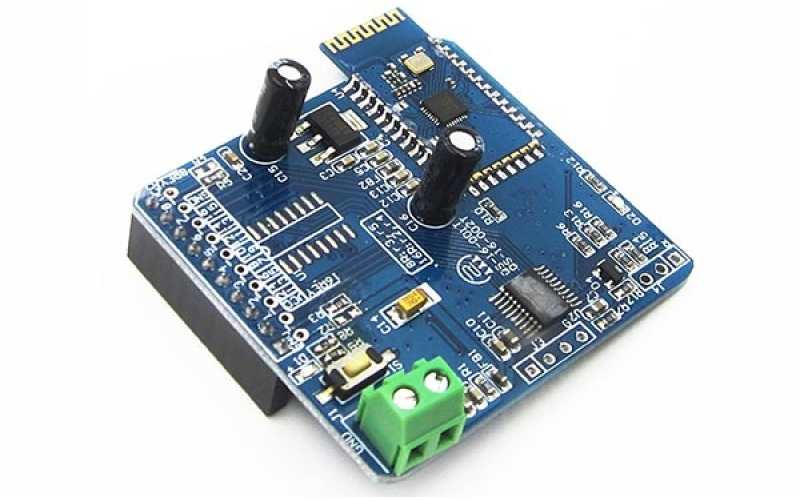

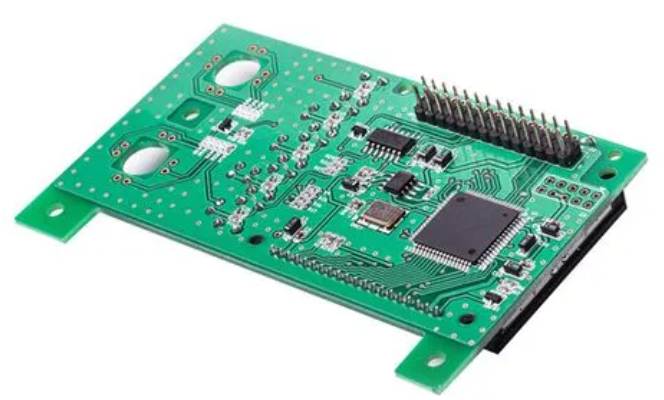

Two, high assembly density

At present, the biggest advantage of SMT patch processing is "smaller, lighter, thinner, denser, better", under this premise, ordinary SMT processing is difficult to reach the standard, and choose the appropriate smt external processing manufacturers, not only can reduce the volume of PCBA board, but also reduce its weight, reduce its area and weight, improve the quality. In addition, SMT patch processing mostly adopts chip components, which are of high reliability, small and light, and require high-precision equipment to produce and process, which can only be completed by professional manufacturers.

Three, the performance is more reliable

Most of the pin lines of SMT components are non-leads or short leads, which are produced manually or by ordinary electronic enterprises, which not only has low efficiency, but also low qualification rate. smt external manufacturers will reduce the influence of parasitic inductance and capacitance through advanced technology, improve the high frequency of the circuit, reduce power consumption.

Four, more money

Some enterprises think that outsourcing SMT patch processing will not only cost more, but also the weight and time will be limited by others, so they think it is better to produce their own. For this point, professionals said, although some smt external processing there are some problems, but generally speaking, or more advantages than disadvantages.

First of all, the enterprise needs to configure the corresponding equipment, instruments, technology, personnel and various testing tools, personnel, etc., which consumes a lot. After smt external processing, it only needs to pay the smt processing cost and start-up cost, and there is no need to worry about the rest.

Secondly, smt external processing manufacturers have rich experience, advanced equipment and mature technology, which can guarantee the quality and output and deliver the production within the agreed time. In this way, relative to their own production, external processing is more cost-effective. As can be seen from the above introduction, smt external processing is much better than self-production, especially with the improvement of electronic enterprises' technical requirements for SMT patch processing, only professional SMT patch processing manufacturers can complete enterprise tasks and meet the standards expected by enterprises. Therefore, it is better to outsource it directly than to expend effort and worry and save money.