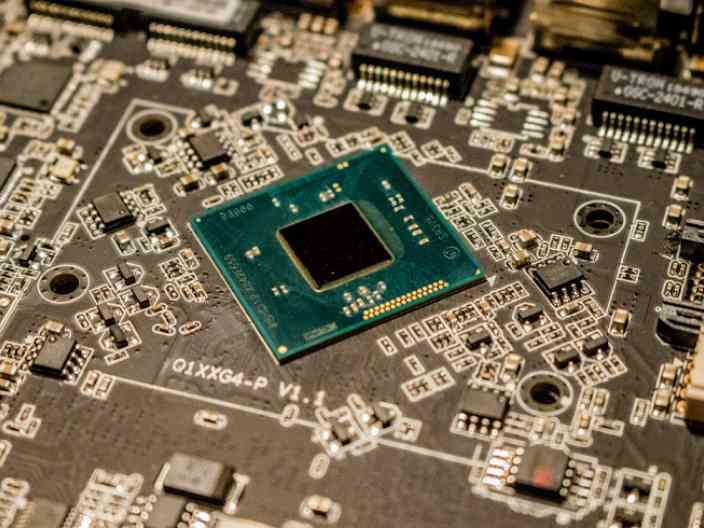

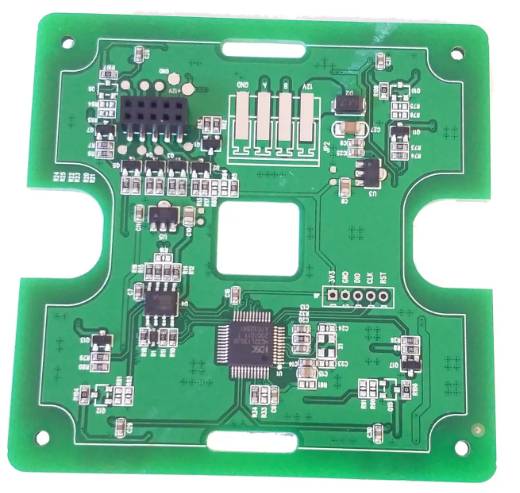

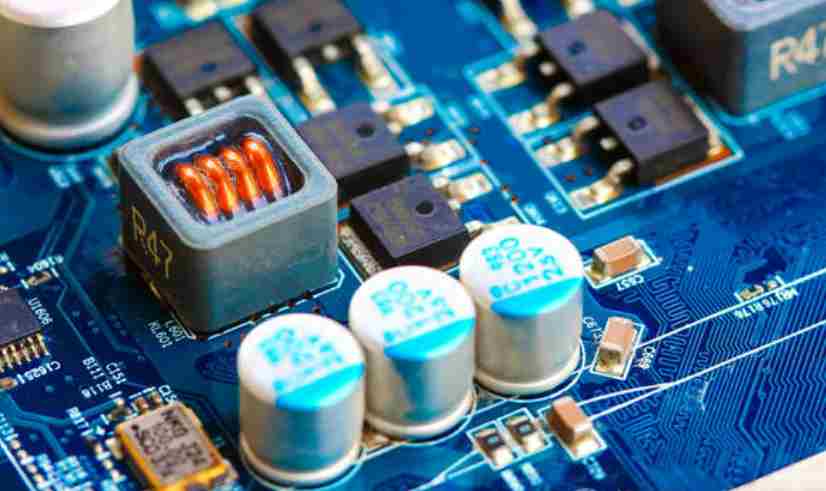

Solfort Technology has successfully completed the PCB design of a multi - pin communication board. The technical parameters of the board are more than 60K pins, and the layout space of the board is compact. The client requires that PCB deSIgn, si simulation and PCB manufacturing be completed within 2 months. Before the final determination of the client's schematic diagram, PCB design has begun, which is equivalent to reviewing the schematic diagram, modifying the scheme for design, and si simulation at the same time. There are many types of power supply with small voltage and large current on the board.

Interface type :SFP+, Interlaken, QPI, PCIE3, DDR4, and DDR3 signals

Standards :SFF 8431, QPI 3.0, PCIe 3.0, Jesd79-4, Jesd79-3e, etc

Speed:

1.pcie 3.0-8 Gbps;

2.pcie 2.0-5 Gbps;

3.QPI-8 gigabit/s;

4.DDR 4-2133 Mbps;

5.DMI-5 Gbps;

6. Interlaken -12.5 Gbps/10.3125 Gbps;

7.DDR 3-1600 Mbps;

8. serdes-10.3125 Gbps;

Simulation description:

The project layout is relatively dense, with many types of power sources and high signal speed. The highest signal rate is 12.5G, which requires the PCB wiring level to be planned in place and signal quality to be guaranteed. After SI simulation was confirmed, TU872SLK-sp with relatively small dielectric constant was finally used to design PCB with high speed signal. Power channel needs overall planning, large current power supply to ensure sufficient current plane, and ultimately meet customer design requirements.

The inventory data source mainly includes the accuracy of the basic data of the warehouse, the setting of the warehouse type, the setting of the warehouse location, the setting of the warehouse transaction type parameters, etc. Among them, the arrangement of the basic data of the warehouse is very important. If the previous warehouse management is more standardized and the accounts conform to the higher rate, it is just to import these accounts into the system. If the account match rate is low, it will take a lot of effort to sort out the number of accounts in the warehouse. First of all, it is necessary to standardize the receipt and delivery management of the warehouse in terms of the process, including the ten principles of warehouse management. Whether it is borrowing materials, replenishing materials or returning and replacing materials, it is necessary to operate in strict accordance with the process, establish a set of effective performance assessment methods for the warehouse keeper, and strengthen the spot check of the daily work of the warehouse keeper. For some parts with large quantity difference, we can take the method of cycle counting to check them, correct mistakes and find out the reasons for the difference. Only in this way, the warehouse accounts will be more and more accurate. Especially in the early stage of the ERP system switching, although some inventory numbers are not very accurate, we still have to insist on using the number of accounts in the system, resolutely discard manual accounts, and only keep one set of accounts. Only after such an run-in period, the data of the system will become more and more accurate.

The material operations often used in inventory management are based on the warehouse and warehouse location, including the establishment of warehouse location (LMMT), warehouse transfer (IMTR), material issue (PICK), etc. All inventory business of the enterprise involves the warehouse, mainly inside and outside the factory, rented warehouse, workshop warehouse, backwash warehouse, etc., which should be included in the system management and clearly defined. When setting up a warehouse, you first define the type of the warehouse. In manufacturing enterprises, warehouse types can be set up: raw material warehouse, spare parts warehouse, semi-finished products warehouse, finished products warehouse, waste warehouse, etc. The setting of warehouse data can be carried out according to different types of warehouses, and multiple warehouses can be set according to different requirements of the same type. Before setting the warehouse location, you can partition the whole warehouse, that is, set the reservoir area.

In ERP system, the reservoir area is mainly set in physical directions, such as east, west, south and north. Or according to the division of the field, in order to partition. Warehouse location refers to the shelves for material storage in the warehouse, which are divided according to location and function to store materials of different categories or in different states. If materials should be stored separately before and after quality inspection, two storage locations should be set up to distinguish, one is to be inspected, the other is qualified products. The storage location can facilitate the organization of materials in the warehouse, as well as the management of materials in and out of the warehouse.