Many chemicals or materials containing chemicals are used in the SMT patch process, such as cleaning agent, flux, thinner, binder, filler, solder paste, etc. Therefore, strict training must be carried out before operation, and the following requirements should be paid attention to during operation. Chemicals should be stored in designated areas, away from the work area, and at a specified safe distance, and must be equipped with safety facilities. The following patch processing manufacturers will tell you how to properly store the patch processing materials and how to deal with the waste circuit board recycling knowledge

1. How to recycle waste circuit boards

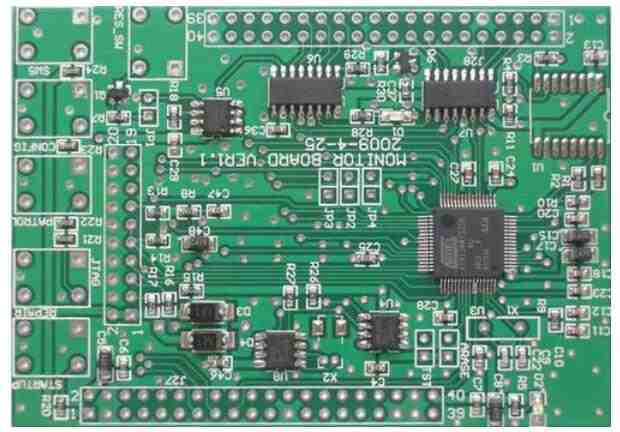

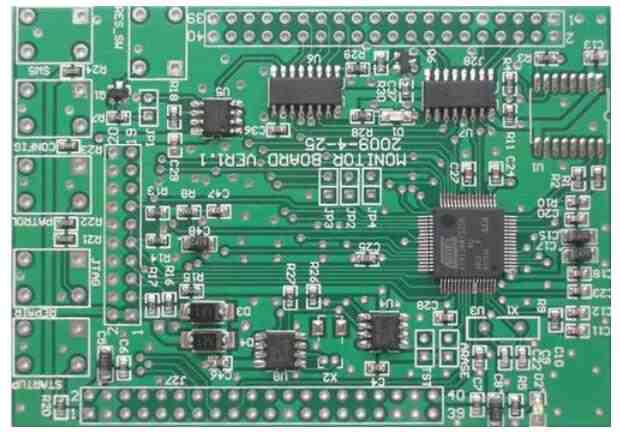

Circuit boards are embedded in almost every electronic device in the modern world, from children's toys to corporate networking equipment. Circuit boards contain the largest amount of precious metals of any type of computer component. According to the United States Geological Survey, one metric ton of computer scrap contains more gold than 17 metric tons of gold. As a result, circuit boards are one of the most valuable commodities in the technology recycling industry. However, circuit boards contain materials that pose a serious threat to human health and the environment if not handled properly.

Why is the circuit board e-waste

There are certain commonly used materials that can make boards of any size or capacity particularly dangerous. First, the circuit itself contains harmful elements. Some manufacturers use tin-lead welding alloys to protect the conductive copper on the plate from oxidation. Lead is harmful to the environment. Components embedded in the board (such as batteries, switches or relays) contain a variety of potentially toxic materials. This includes cadmium, lithium and mercury. It is extremely difficult to effectively strip circuit boards of these harmful materials due to their complexity and dense density. Secondly, improper disposal of the board itself can produce pollutants. Board substrates often contain polybromine flame retardants. Brominated flame retardants release two highly toxic chemicals when heated: dioxins halide and furans. According to e-Stewards, these chemicals are "some of the most toxic substances known to man."

Where do I recycle the boards

SMT processing: Certified recyclers to dispose of old circuit boards is absolutely vital. Because circuit boards contain large amounts of precious metals, they are prime candidates for illegal export by unscrupulous recyclers. The boards are shipped overseas and then burned in a crude smelting technique to recover the metal. In unregulated conditions, hazardous substances such as lead, mercury, dioxins and furans can leach into the local environment, contaminating water and food supplies and seriously damaging community health. Certification requires certified recyclers to be responsible for downstream disposal of e-waste materials. This prevents illegal exports and unsafe handling of items such as circuit boards.

2. How to keep the materials for patch processing properly

I. Storage of patch processing materials

Due to the various kinds of materials used in the SMT production process, the storage of materials must be very strict, and no error or damage is allowed. The operation must be carried out in strict accordance with the operating specifications and procedures, and the provisions of material management must be strictly followed. Materials should be stored in designated areas, sorted, neatly placed and marked. When handling and using materials, handle them with care, use special appliances, and operate according to operating regulations to prevent damage. Store materials with special requirements, such as temperature, humidity, electrostatic protection, and safety distance. For patch processing materials that have time requirements for storage and use, the regulations must be strictly followed.

2. Custody of harmful substances

Due to the possible exposure to harmful substances during SMT production, SMT patch processing operators must undergo strict training before operation, strictly follow the operating specifications and procedures, and keep and dispose of harmful substances in strict accordance with relevant regulations. Hazardous substances should be stored in the designated area and location, away from the work area, and above the prescribed safe distance, and must be equipped with safety facilities. When transporting and using hazardous substances, protective equipment must be worn and operation procedures must be followed. If hazardous substances occur, corrosion, ignition, must be in accordance with the operating standards and regulations to operate, to prevent the expansion of the accident at the same time. The time to call the fire alarm 119, clear the exact location of the accident, and quickly scattered sulfur. For the waste containing harmful substances, it must be operated in a timely manner according to the operating standards and procedures, and handled according to the provisions to prevent the occurrence of accidents. For the discharge of harmful substances, the following standards shall be strictly implemented. "GB4-73" industrial "three wastes" discharge standard "stipulates that the emission concentration of harmful substance lead <" TJ36-90 "industrial enterprise design health standard), harmful substance lead smoke concentration <" GB7355-87 health standard of lead and inorganic compounds in the atmosphere ", The average daily high admissible concentration of lead and its lead-free compounds in the residential atmosphere is 0.0015mg/m³.

Third, prevent chemical damage.

Many chemicals or materials containing chemicals are used in the SMT patch process, such as cleaning agent, flux, thinner, binder, filler, solder paste, etc. Therefore, strict training must be carried out before operation, and the following requirements should be paid attention to during operation. Chemicals should be stored in designated areas, away from the work area, and at a specified safe distance, and must be equipped with safety facilities. When handling and using chemical materials, you must wear protective equipment and follow the operating rules. When chemical substances leak, corrode or ignite, they must be operated in accordance with operating codes and regulations to prevent the expansion of accidents. After the chemical is used, it must be operated in a timely manner according to the operation specifications and procedures, and put back in the specified container to prevent potential accidents.