1, what is the combination of soft and hard board?

Soft and hard combined board refers to the combination of soft board and hard board, is the combination of thin layer of flexible bottom and rigid bottom, and then laminated into a single component, the formation of the circuit board, has the characteristics of bending and folding. Moreover, rigid flexible bonded plate has high impact resistance and can survive in high stress environment. Due to the mixed use of various materials and multiple manufacturing steps, the processing time of rigid flexible bonded plate is longer and the production cost is higher.

Rigid flexible plates are extremely versatile, ideal for military, aviation and medical devices, and can also be used in medical devices such as pacemakers to reduce space and weight; At the same time, it is also widely used in various smart devices, test equipment, mobile phones, digital cameras and automobiles. It has many advantages as follows:

(1) can effectively save space on the circuit board and eliminate the use of connectors or HotBar manufacturing process.

Because the FPCB hardboard has been combined, the space required to use the connector or HotBar process can be eliminated. For some boards with high density requirements, missing a connector space is like finding a treasure.

This, in turn, eliminates the need for parts to use connectors or HotBar processes. In addition, the space between the two boards will be tighter by eliminating the need for connectors.

(2) signal transmission distance is shortened, speed is increased, can effectively improve the reliability.

The traditional signal transmission through the connector is "circuit board → connector → soft board → connector → circuit board", and the signal transmission of the hard and soft composite board is reduced to "circuit board → soft board → circuit board", the signal transmission distance becomes shorter, the problem of signal transmission attenuation between different media is also reduced, the general circuit board above the line is copper, The contact terminal of the connector is gold plated, solder pin is all tin plating, and need to use solder paste welding on the circuit board, signal transfer between different media will inevitably some attenuation, if you use soft and hard combined board, these media will become less, signal transmission ability can also be relatively improved, for some signal accuracy of high demand products, Helps improve its reliability.

(3) Simplify product assembly and save assembly time.

The combination of hard and soft board can reduce the man-hour of SMT printing because the number of connectors is reduced. It also reduces machine assembly time by eliminating the need to insert soft plates into connectors or HotBar processes. It also reduces the cost of parts management and inventory, because the BOM is reduced, so the management is less.

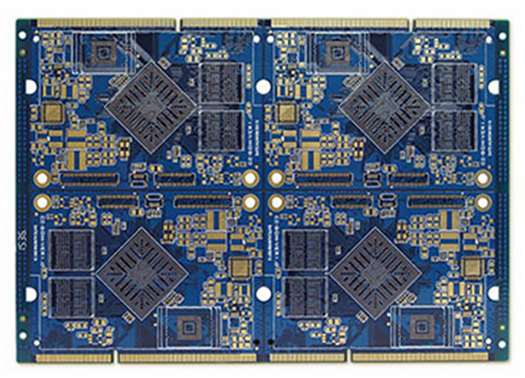

2. What is a high frequency plate?

PCB high frequency board refers to the special circuit board with high electromagnetic frequency, which is used for PCB in the field of high frequency (frequency greater than 300MHZ or wavelength less than 1 m) and microwave (frequency greater than 3GHZ or wavelength less than 0.1 m). It is a circuit board which is produced by using part of the manufacturing process of the common rigid circuit board or by using a special processing method on the microwave-based copper clad board.

The high frequency circuit board with induction heating technology has been widely used in the communication industry, network technology and high speed information processing system, meeting the requirements of many high precision parameter instruments. Reliable high frequency circuit board, in the actual production to provide a great help. So, what are the advantages of such a powerful high-frequency circuit board?

(1) High efficiency

The loss of high-frequency circuit boards with small dielectric constant will be small, and the advanced induction heating technology can meet the requirements of target heating, and the efficiency is very high. Of course, while focusing on efficiency, it also has the characteristics of environmental protection, which is very suitable for the development direction of today's society.

(2) Fast speed

The transmission speed is inversely proportional to the square root of the permittivity, meaning that the smaller the permittivity, the faster the transmission speed. This is exactly the advantage of high frequency circuit board, it uses special material, not only to ensure the characteristics of small dielectric constant, but also to maintain the stability of the operation, is very important for signal conduction.

(3) Large degree of regulation

Widely used in various industries for precision metal material heating processing requirements of high-frequency circuit boards, in its field of technology, not only can realize different depth of components heating, but also can focus on local characteristics of heating, whether surface or deep, concentrated or dispersed heating mode, can be easily completed.

(4) Strong tolerance

Dielectric constant and medium, the environment will have certain requirements, especially in the south, wet weather will seriously affect the use of circuit boards. High frequency circuit boards made of very low water absorption materials can challenge such an environment, but also has the advantages of chemical corrosion resistance, high temperature resistance and high temperature stripping strength, so that high frequency circuit boards play a strong performance.

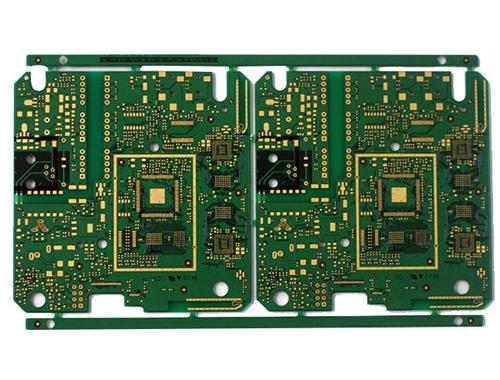

2. What is IC carrier board?

IC carrier board is a technology developed with the continuous progress of semiconductor packaging technology. In the mid-1990s, a new type of IC high-density packaging represented by ball-grid array packaging and chip size packaging came out. As a new packaging carrier, IC carrier came into being.

IC carrier board is also called packaging substrate, in the field of high-level packaging, IC carrier board has become an indispensable part of the chip packaging, not only provides support, heat dissipation and protection for the chip, but also provides electronic connection between the chip and the PCB mother board, playing a "link" role; Even passive and active devices can be embedded to achieve certain system functions. The IC carrier board is a high-end PCB board, just like the rigid flexible binding board. It is developed on the basis of HDI board, has the characteristics of high density, high precision, miniaturization and thin shape.

IC carrier board products are roughly divided into memory chip IC carrier board, MEMS IC carrier board, RF module IC carrier board, processor chip IC carrier board and high-speed communication IC carrier board, which are mainly used in mobile intelligent terminal, service/storage.

According to the different packaging technology, IC carrier board can be divided into lead bonding IC carrier board and flip IC carrier board. Among them, lead bonding (WB) uses fine metal wire and uses heat, pressure and ultrasonic energy to weld metal lead with chip pad and substrate pad tightly to realize electrical interconnection and information intercommunication between chip and substrate, and is widely used in RF module, memory chip and MEMS device packaging.

Different from lead bonding, flip (FC) packaging adopts solder ball to connect chip and substrate, i.e. forming solder ball on the solder pad of the chip, then flipping the chip to the corresponding substrate, and using heating and melting solder ball to realize the combination of chip and substrate solder pad, this packaging process has been widely used in CPU, GPU, Chipset and other product packaging.