A case of "xue Xue Lin" tells you: correct schematic diagram does not necessarily result in correct PCB design.

Both schematic design and PCB design are necessary stages in the R&D process. As we know, schematic design is the front-end process of PCB design. The previous case also analyzed that a wrong schematic will inevitably lead to a wrong PCB design, but can a correct schematic design definitely lead to a correct PCB design?

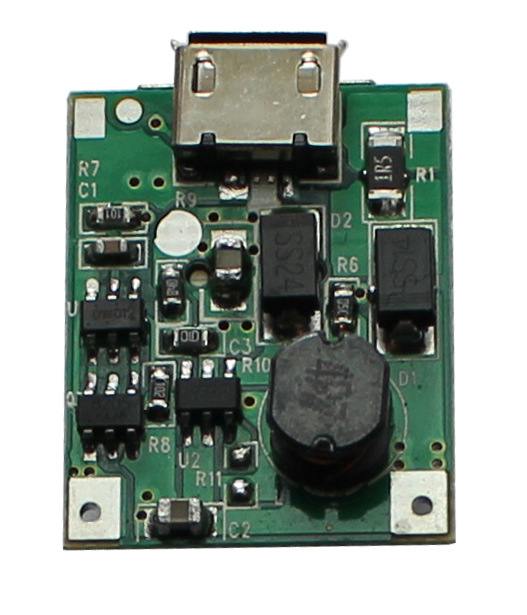

This paper introduces a video transmission module design case, usually using the SDI interface, the rate is not as high as the communication industry, generally to 6G to 12G this interval rate. The board is converted from an FMC chip to a single-ended 75-ohm cable through an equalizer, then into a BNC connector, and finally connected to the device through a cable. The target rate of the customer is 6.25Gbps. It is worth mentioning that the PCB is also designed by the customer company, but processed here.

Originally, it seems that the speed is not too high, so the design difficulty should not be too great. However, when the board is processed, there is a big problem when the customer tests it. The following picture is the information the customer told us and the test result of the eye picture. The customer conducted the test after the BNC connector and found that the eye picture was closed at 6.25Gbps, while the actual functional test also showed that the 6.25G speed could not work, and the frequency could only be reduced to 1.25G. So the client turned to us, Mr. Highway, to see if we could figure it out.

The question is clear, but the answer is vague. Both the customer and our design engineer immediately thought that the 100-ohm difference line in front of the equalizer was caused by a bit of long wire running and a bit of large loss.

However, Mr. Gao Speed is sensible. From the point of view of the wire length, it is less than 3inch. The wire loss will not be a problem. In addition, the input test from the equalizer found that there is a good eye pattern also can prove that the loss is not very large. So it seems the most likely guess is that it's going to be passed.

With the previous experience that there might be problems with the schematic, Mr. Gao Speed gradually paid attention to the schematic design, so after listening to the information provided by the customer, we got the schematic of the customer to check, the result found that there should be no big problem in principle. After the equalizer receives the 100 ohm difference line into a 75 ohm single terminal line, the principle is relatively clear.

However, Mr. Gao Speed still found some unconventional designs. Looking at the wiring part of the 75 ohm single-ended output, the customer also carried out the operation of pulling down through the magnetic bead, which should be used for anti-interference design concept. Mr. High-speed immediately sensed something fishy and focused on this position, comparing the schematic design with the actual PCB design.

Really have a surprising discovery, from the schematic pull-down concept to the realization of PCB must be connected to the magnetic bead through the wire and then pull-down. Then we can see the operation as shown in the figure above, which is connected to the magnetic bead by wiring at the position of BNC interface and then pull down. With his accumulated experience, Mr. Gao Speed immediately concluded that this location was the problem. On the schematic diagram, it was just an ideal connection line, but when it came to PCB design, it immediately became a stub of more than 200 mil. There was a gap between the ideal and the reality, which seemed to have little influence, but actually had great influence!

A 200 mil stub will definitely affect the signal performance of 6.25 Gbps. Mr. High-speed thinks he has found the answer to his problem, so how to convince his customers? General customers are more cautious, unless there is a clear answer, otherwise the customer dare not boldly change the board, so Mr. Gao Speed to see if it is possible to debug on the existing board. Mr. High-speed pored over the PCB file and came up with an interesting idea.

Since 75 ohm routing is just the surface routing, it provides the possibility for the implementation of this idea. The proposed method is also very simple and popular, that is, use a knife to directly cut the stub line at the location of the BNC interface, as shown in the figure above. As for knives, any knife like this is OK!

The customer carried out this operation according to the suggestion of Mr. High-speed, and got a surprise effect! The system was able to successfully run at 6.25 Gbps.

This is the end of the sharing of this case, an open gun is easy to hide, sometimes the stub on the PCB design is very hidden, a little careless, will fall into the stub without knowing it. The description on the schematic diagram really has a lot of possibilities in PCB design. In the high-speed era, the ideal wiring on any section of schematic diagram has become an unsatisfactory wiring on PCB, bringing a variety of unexpected high-speed problems. Therefore, PCB engineers also need to accumulate experience and theoretical knowledge, in order to remain invincible in the high-speed era!