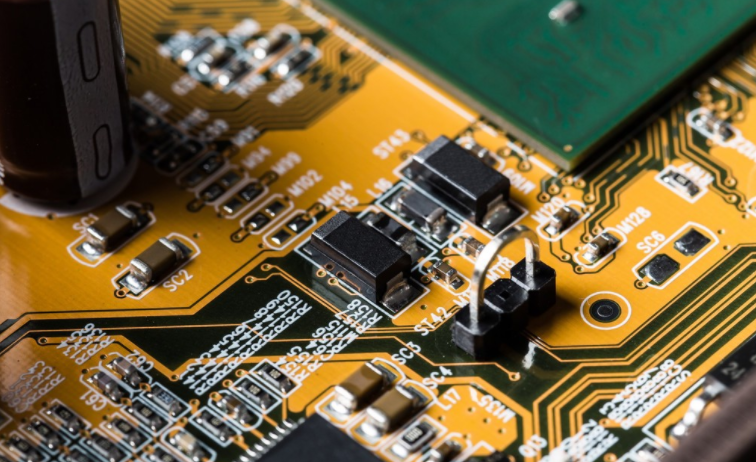

PCBA hole wall has copper particles and copper wires

Abstract: Is there any hole in the copper processing, copper particles and PCB hole wall on the surface, and what is the problem with the solution? What is the SAP process?

The industry generally defines primary copper as the process of removing 3 kinds of glue residues, chemical copper and complete plates. Pores, copper particles and copper wires will appear in the pore wall of PCBs. These problems are usually not copper problems, but problems caused by chemical copper precipitation or slag discharge process. In the process of fecal treatment, the circuit board will go through three treatment processes: filler, oxidant and reductant. If the solution ages in the reduction process, permanganate residues may remain on the PCBs pore wall and cannot be completely removed. When this kind of circuit board enters the process of electroless copper plating, it will be corroded by the micro etching solution, resulting in partial stripping. At this time, the active layer formed by the pore forming agent will be destroyed, resulting in serious growth of chemical copper and pore fracture.

Circuit board

Of course, the chemical process of copper itself will also cause the opening problem For example, the chemical activity of copper is insufficient, the pore depth is too large, the chemical copper cannot be processed, the use of metal modifiers, palladium pores and colloid problems will also affect the overall quality of polychlorinated biphenyl hole w If the drill is of poor quality, this hole is easier to break Especially, if the PCB hole wall is too thick, it will cause problems such as poor cleaning and residual liquid Hole are relatively prone to occur The most common source of problems is poor brushing and copper chemical roughness the integrity of the extraction rack and substitution of chemical liquids are feasible methods In particular, it is necessary to avoid mixed copper chemical micro engraving and select grating processing grooves Such problems are usually found in foundries and occur in factories with limited workplaces When the two are mixed, the colloid left in the grid stripping process will precipitate into the pores, and the PCB hole wall will be very difficult From this point of view, in order to eliminate these problems, it is not only necessary to mix storage tanks, but also pay attention to palladium colloid and water washing filtration circulation system Only in this way can the PCB pore wall be minimized

If PCBs are allowed, the company can also consider using the direct coating process. This process does not have the problem of palladium colloid, but due to the structure of the circuit board and past historical experience, some system suppliers have limited the use of this technology. This is the first step in establishing the process. Please consider this part. Processes such as "shadows" and "black holes" represent such technologies, which can also enhance copper particles on the walls of PCBs.

The full name of SAP is "semi additive process", because there are two general circuit production methods: full etching and partial etching. This partial etching method can produce stronger circuits and finer circuits. In this case, if the external circuit of an ordinary circuit board is very thin, the SAP process can be considered for making the circuit. In recent years, the requirements for circuit production are more and more accurate. In this case, some circuit boards are made of all chemical copper based method. Today, most industries use the so-called SAP process, which is a practice.

In fact, all circuit board production methods can be called SAP process, but their basic copper thicknesses are different. However, the current industry believes that only alkaline copper is a pure chemical copper process should be called chemical copper In addition, in the field of structural load panels, the industry partially uses ultra-thin copper cladding to make circuits At this time, a different name "M-SAP" is added This M stands for metal, which means copper At this time, manufacturing technology is not the basis of pure copper, but ultra-fine copper The above contents are for reference only