Needle bed detector on chip processing line

Needle bed detector on SMT chip processing line

On line test ICT is a test method to check manufacturing defects and defective components by testing the power efficiency and power connection of online components. ICT is a contact detection technology with strong fault diagnosis ability, which has been widely used. The shape memory alloy is placed on a specially designed needle bed clamp. The spring test probe mounted on the fixture contacts the component leads or test pads. Because it contacts all the networks on the board, it can test all analog and digital devices separately. And it can quickly diagnose faulty equipment.

In ICT, due to the long cycle of production and program development of the needle press fixture, the price is relatively high. At the same time, due to the limitation of the CNC machine tool of the processing equipment when processing the needle press fixture, the test probe must be designed on a 2.54 mm or 1.27 mm grid, so that the minimum distance between probes is 1.27 mm. Therefore, ICT is applicable to products with general assembly density and mass production.

Patch 3 of LED high-power lamp board

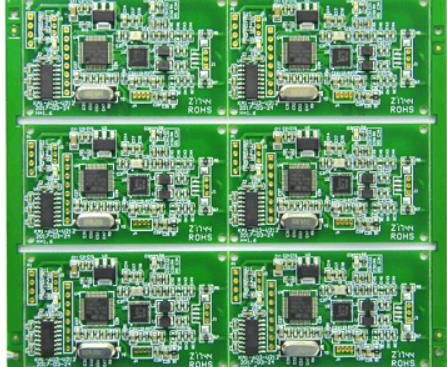

Circuit board

At present, there are two types of ICT instruments: one is manufacturing defect analyzer (MDA), the other is that ICT0 MDA is actually a simplified form or early product, which can only be used for analog testing, mainly for analog circuits. Testing of component boards. MDA usually uses voltmeter, ammeter, ohmmeter and other instruments to complete the measurement, and controls the entire measurement process through software and programs. Detectable defects, such as whether the components are missing, whether the polarity is standard, resistance, capacitance, diode, triode related errors, etc. Because it does not drive SMA, it does not have the actual function of testing digital devices. Its greatest advantages are fast programming, low cost and fast test response. At present, electronic products have entered the digital era, and MDA has basically exited the testing field. ICT is far more powerful than MDA. In addition to all functions of MDA, ICT can also perform online testing on digital devices. ICT can detect almost all defects related to the manufacturing process, which is now widely used.

Handling of ICT basic components in SMT factory

The needle bed online test system consists of five subsystems: computer control system, measurement subsystem, signal excitation subsystem, signal management, switch conversion system and test access fixture, as well as user interface and tested circuit components.

The computer control system includes computer hardware, various communication interfaces, test operation software modules, graphical user interfaces, peripheral equipment, etc. The measurement subsystem is a collection of various program controlled measuring instruments and auxiliary test modules in the online test system. It is a method of detecting the circuit components under test in response to the excitation signal. Data comparison. Signal excitation subsystem is also a collection of program controlled signal sources, such as power supply, integrated signal generator, counter, etc. During the test, the excitation signal suitable for the test is automatically selected according to the programming control instructions and loaded into the tested circuit assembly.

SMT Processing SMT-QAS Design Factory

The switch conversion system mainly controls the system to automatically switch to the selected test channel according to the programming instructions, and plays the role of loading the excitation signal, connecting to the measurement subsystem, and connecting the test needle bed and the probe. A good online test equipment should have a simple, easy to understand, intuitive and easy to use graphical user interface. At present, the online test equipment basically adopts the Windows operating system and the test and debugging program design system. These devices can be programmed to select the appropriate test channel number according to the tested object through the graphical interface, and observe the excitation and response signal waveforms during the test.

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.