SMT Factory Reflow Welding Temperature Curve

About PCBA Factory Reflow Welding Temperature Curve and Welding Process Setting

The characteristics of solder paste determine the basic characteristics of reflow temperature distribution. Due to the different chemical compositions of alloy solder powder and flux, different solder pastes have different requirements on temperature and reflux temperature curves due to their chemical changes. Generally, solder paste suppliers can provide reference reflow profiles, on which users can optimize according to their product characteristics. Taking Sn96.3 Ag3.2Cu0.5 lead-free solder paste with a melting point of 217 ° C as an example, two typical temperature distributions are introduced.

1) Conventional temperature curve

The traditional temperature curve is divided into four main stages: preheating zone, insulation zone, reflux zone and cooling zone. This temperature distribution has a holding time in the heating process. The surface temperature of this shape memory alloy is relatively uniform. Even if PCB components are uneven in size and are assembled with relatively high density, the surface temperature of the shape memory alloy is still relatively uniform. This temperature curve is required when the component size on PCB is uneven and the assembly density is relatively high.

(1) Warm-up stage. The temperature of this PCB is heated to 150, and the heating rate is less than 2 T/s, which is called preheating The purpose of the preheating phase is to volatilize the low melting point solvent in the solder paste The main components of flux in solder paste include rosin, activator, viscosity improver and solvent The solvent is mainly used as the carrier of rosin and ensures the storage time of solder paste During preheating, too much solvent needs to be volatilized, but the heating rate must be controlled Too high heating rate will cause thermal stress of components, damage components or reduce the efficiency and life of components, which will bring greater harm Another reason is that too high heating rate will cause the solder paste to collapse and cause the risk of short circuit. Too high heating rate will cause the solvent to evaporate too quickly, and it is easy to spill metal parts and lead to solder beads

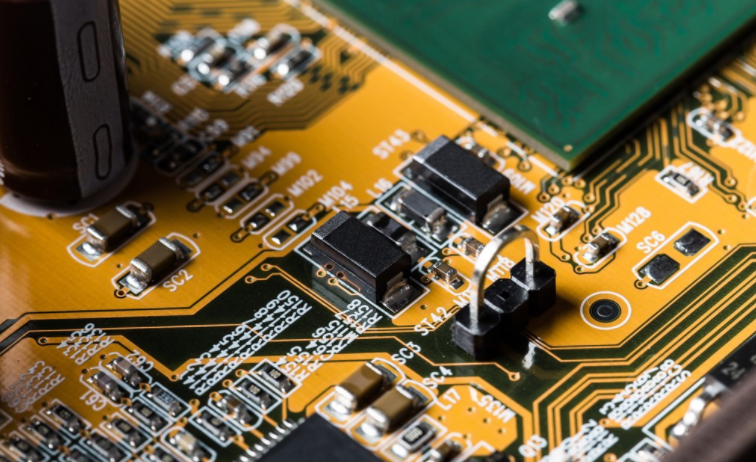

Circuit board

(2) Insulation stage. Slowly heat the whole circuit board to 170 to make the circuit board reach a uniform temperature, which is called soaking or balancing stage. The time is generally 70~120 seconds. At this stage, the temperature rises slowly. The setting of the thermal insulation stage should mainly refer to the recommendations of the solder paste supplier and the thermal capacity of PCB. The insulation stage has three functions. First, make the entire PCB reach a uniform temperature, reduce the impact of thermal stress entering the reflow zone, and other welding defects, such as component lifting.; Second, the flux in the solder paste starts the reaction, adding the wettability of the surface of the weldment, so that the melted solder can well wet the surface of the weldment; The third is to further volatilize the solvent in the flux. Due to the importance of the heat preservation stage, the time and temperature of heat preservation must be effectively controlled. It is necessary to ensure that the flux can well clean the welding surface, but also to ensure that the flux is not completely consumed before reaching the reflow stage, which can prevent reflow stage. The role of reoxidation.

Processing of main board PCBA

(3) Reflow phase. The circuit board is heated to the melting area to melt the solder paste. The circuit board reaches the maximum temperature, usually 230~245, which is called the reflow stage (reflow). The time higher than 0 liquidus is usually 30~60. In this reflow stage, the temperature continues to rise and pass through the reflow line. The solder paste melts and has wetting reaction, starting to form an intermetallic compound layer, and finally reaching the peak temperature. The peak temperature of the reflow phase is determined by the chemical composition of the solder paste, the characteristics of the components and PCB data. If the peak temperature in the reflux stage is too high, the circuit board may be burnt or scorched; If the peak temperature is too low, the solder joint will appear dark and granular. The peak temperature of this temperature zone shall be high enough to make the flux fully effective and have good wettability, but not too high to cause damage, discoloration or burning of components or circuit boards. In the reflow phase, the temperature rise slope shall be considered, and the components shall not be subject to thermal shock. On the premise of ensuring good soldering of components, the reflow time should be as short as possible, generally 30~60s. Too long reflow time and high temperature will damage parts susceptible to temperature, and will also lead to too thick intermetallic compound layer, which will make solder joints very brittle and reduce the fatigue resistance of solder joints.

(4) Cooling phase. The cooling process is called the cooling stage, and the cooling rate is 3-5. The importance of the cooling phase is often overlooked. A good cooling process also plays a key role in the final result of welding. Faster cooling speed can refine the microstructure of solder joints, change the morphology and distribution of intermetallic compounds, and improve the mechanical efficiency of solder alloys. For lead-free welding in actual production, improving the cooling rate can usually reduce defects and improve reliability without affecting the components. However, too fast cooling rate will cause impact and stress concentration on components, and lead to premature failure of product solder joints during use. This, reflow soldering must provide a good cooling curve.

2) Pentium like temperature curve

The tent temperature curve is divided into the main stages of heating zone, preheating zone, rapid heating zone, re circulation zone and cooling zone. Using this temperature curve, the heating rate of SMA from room temperature to peak temperature is basically the same, and the thermal stress on SMA is small; However, when the components on the PCB to be welded are uneven, the surface temperature of the shape memory alloy is not uniform enough; The welding temperature of components with large quality and high heat absorption cannot meet the requirements. This temperature curve is mainly applicable to the situation where the component size on PCB is relatively uniform.