Conclusion and prospect of copper foil materials for FPC

PCB manufacturers, PCB designers and PCBA processors will explain the conclusions and prospects of copper foil materials for FPC

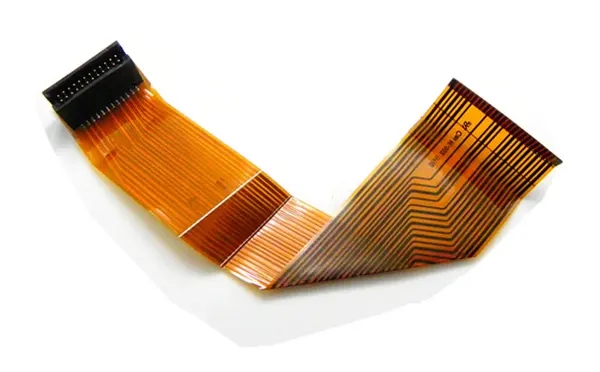

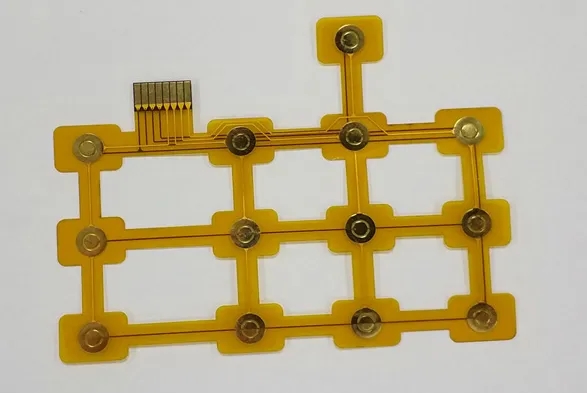

Flexible Printed Circuit Board (FPC) is referred to as "flexible Board", commonly known as FPC in the industry. It is a Flexible insulating substrate (mainly polyimide or polyester film) The printed circuit board has many advantages that the hard printed circuit board does not have. For example, it can bend, wind and fold freely. The volume of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products.

In response to the rapid development of circuit boards, copper foil will play a more important role in the future. From the production equipment, communication facilities, business equipment, transportation system, and domestic demand, it is gradually oriented to electronic. For example, the demand for computer overspeed and general electrical appliances, circuit boards still have a lot of room for growth. Especially FPC, which is used in portable communication products, will have more room for market growth than hard boards driven by mobile phones, flat panel displays and other industries. In particular, the technology to replace the circuit board has not achieved concrete results so far, and it can be expected that the circuit board industry will still have substantial development and growth space in the future.

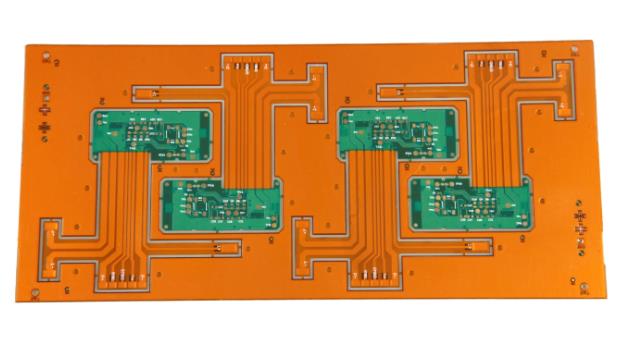

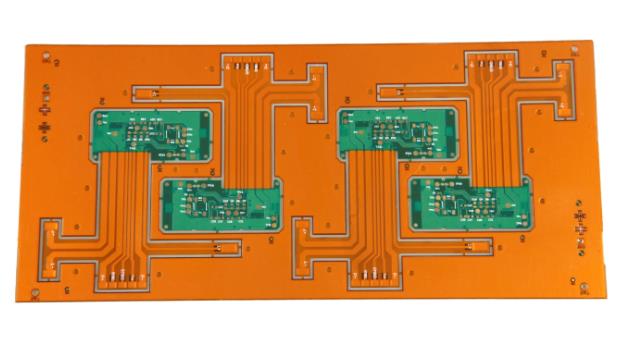

In addition, due to the high replacement frequency of electronic products, the demand for copper foil products with high performance and high added value is also increasing. At the same time, in order to meet the world green environmental trend, the industry also has an increasing demand for lead-free, halogen-free substrates and new materials emerging at the historic moment, such as high temperature resistant high Tg (>180 ℃) copper foil substrates. In addition, the development of PCB towards high-tech multi-layer and high-density, and how to reduce costs have become two major growth keys. For example, for the sake of small size and light weight of the machine, FPC boards are selected, which is also suitable for the integrated concept of containing external hardware cases, making the use of circuit boards more extensive. Circuit board manufacturers continue to develop new materials to achieve this goal, which has led to many new products. In particular, in order to reduce costs, their manufacturing methods continue to be more simple, high production rate and high yield Roll to Roll continuity Consistent production.

Looking around the trends and development trends of the global electronics industry, the application and growth of soft boards will increase with each passing day. The copper foil industry is bound to adopt diversified management. For high-performance and continuous production and manufacturing of copper foil substrates, it can be expected that the requirements for copper foil quality and performance will only be more stringent. Therefore, how to break through the technical bottleneck, mass produce in a higher and more efficient way, and make full use of existing electrolysis methods to produce ultra-thin copper foil with high elongation. In addition, in order to reduce manufacturing costs and simplify the management and control of multiple types of products, it is more important to develop copper foil products of any thickness, which have special physical, chemical, metallurgical and mechanical properties in terms of quality, and can meet the demand for copper foil characteristics required by various soft and hard board materials in the laminate industry. That is, the "universal copper foil" that combines soft and hard materials should be the goal that the copper foil industry has long dreamed of. PCB manufacturers, PCB designers and PCBA processors will explain the conclusions and prospects of copper foil materials for FPC.