Core driving force for PCB manufacturing of automotive electronic products

This advanced and innovative world enables automotive electronics to come up with new ideas and technologies every other day Unmanned vehicles, electric vehicles, hybrid electric vehicles, dual fuel vehicles and recent hot discussions in the automotive industry have driven the development of miniaturization, multi-function applications, and robust and compact electronic solutions With this, safety and security are becoming the focus of automobile manufacturers and other original equipment manufacturers It is also an arduous task for vehicle manufacturers and manufacturers to select the most suitable safety PCB for vehicle electronic applications Printed circuit boards require appropriate coatings to improve durability and life expectancy Among them, conformal coating protects PCB components from environmental pressure This paper summarizes the importance of conformal coating and how it can improve PCB efficiency of automotive electronic products

What has become the core driver of PCB manufacturing of automotive electronic products

Nowadays, the luxury function of cars is becoming the common demand of consumers. The standard functions of the vehicle include rear monitor, automatic parking system, lane departure warning system, driving assistance system, etc. Although high-tech car software for navigation, communications, networking, music and other technologies is becoming commonplace.

More and more electronic products are used in new cars, so it is necessary to pay attention to the security and security solutions of electronic products. Current cars have a built-in system for airbag control, automatic transmission, fuel injection system, electric windows, suspension control and engine control module. This makes researchers and researchers not only focus on vehicle software, but also on high-quality hardware and hardware. For original equipment manufacturers and automobile manufacturers, this is becoming a huge challenge. It is necessary to determine the perfect PCB used in manufacturing in order to provide protective automotive electronic products in the next generation of innovation.

Engineers now seem to have adopted different solutions to protect PCBs in automotive applications After considering various options of placing the circuit board in the shell or the circuit board, resin can be used to draw. The best design of the pipe PCB component to obtain the safe is to use conformal coating Therefore, first of all, we will deeply study the meaning of conformal coating

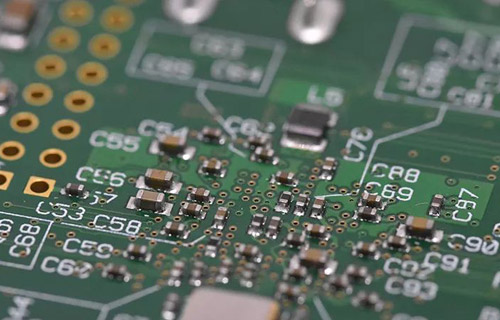

Circuit board

The polymer coating is applied to the polymer in the thin layer of circuit board to electrically insulate PCB components and protect them from environmental stress. These types of coatings are best suited for compact PCBs because they take up less space. There are many ways to apply conformal coatings to printed circuit boards. Robotic dispensing, spraying, flow coating or brushing are methods to apply such coatings according to production type, whether in large-scale, low level or medium level production. This safety coating can also improve the efficiency and durability of PCB, because it can protect the circuit board from moisture, thermal stress and mechanical stress, pollutants and corrosives (including fungi, salt, toxic gases and dirt).

In addition, most lead-free PCB components used in automotive projects have noticed that "tin whiskers" are a common challenge, which stimulate the growth of short circuits caused by thermal and mechanical stresses. This growth rate can be reduced by preventing short circuit and arc in conformal coating in PCB. By adding mechanical support, the advantages of conformal coating in PCB can be added, and the fatigue life of solder joints can be improved.

The printed circuit board shall be placed anywhere suitable for the vehicle control system. From brake fluid to gasoline to internal combustion engine, PCBs need the correct coating type without affecting the vehicle manufacturing process. PCB with conformal coating is the main driving force to ensure electronic solutions in the automotive field.

Depending on the type of PCB and its use, these conformal coatings can provide a wide range of choices Polyurethane acrylate, silicone adhesive, solvent based formula and two-component epoxy resin are safe coating chemicals Although UV curable coatings have their own advantages, they can provide protective PCB solutions for automotive electronic products Then, select the appropriate coating for PCB manufacturing needs to work with PCB manufacturers and PCB experts They can provide appropriate guidance for the selection of protective coatings for PCBs used in automobiles and other automotive electronic products They perform qualification and environmental testing to determine the conditions under which the coating is most suitable for a particular application These investigations include temperature limit test, wear, humidity, vibration, chemicals, salt spray and other hazards