PCB? Here are some detection methods:

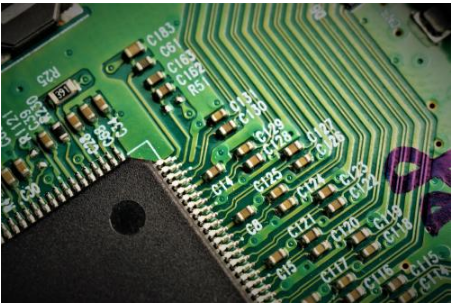

The circuit board learned to establish relevant application software on the PCB, and adopted the idea of virtual instrument, that is, to realize various functions of traditional instruments through software, including oscilloscope, signal generator, and various mathematical processing of collected data. During the test, digital signals are given through the test software.

The PCB board test system will have a new idea. The design idea of automatic test system and virtual instrument based on USB bus is adopted, which gives full play to the role of the computer. The idea of replacing traditional instruments with computers is tried to reduce the volume of the instrument itself, reduce the development cost, and improve the development efficiency.

After D/A conversion, the analog excitation signal required for the test is applied to the test system, and then sent to the switch matrix by the test circuit through the test bus. The switch matrix is connected to the switch matrix and controlled by the microprocessor at the same time. The PCB under test is fixed on the needle bed. The excitation signal is applied to the corresponding position of the printed circuit board, and its response is measured by the test circuit. The collected analog quantity is sent to the core control, After A/D conversion, the corresponding digital quantity is obtained, which is fed back by the software on the PCB and processed by the PCB to determine whether the PCB is qualified.

Circuit board production

The online testing technology has broken through the previous method of using human eyes to detect circuit boards. The online testing technology has high efficiency, low leak rate, and has realized automation in the detection field. This detection system adopts the idea of combining with virtual instrument, which reduces the hardware design and the cost of the whole system.

The testing system is suitable for the application of small and medium-sized enterprises. It reduces the number of unqualified products entering the next process, thus reducing the rework of products, improving the efficiency, reducing the total cost of manufacturing, and improving the profits of enterprises. It is a widely used detection technology and a highly efficient, high-speed and high-precision detection method.

At present, PCB boards are used in the field of automatic testing of printed circuit boards in a wide range of tests, including the test of components not installed and the test of components installed. Currently, the commonly used test methods are: on-off test, in circuit test, function test, edge test, optical test and X-ray detection. Online testing is to select an appropriate testing method according to the specific characteristics of PCB board to combine one or more processes, learn from each other and use them comprehensively. Professional PCB manufacturer, PCB design solution service provider.