What is the meaning of PCB impedance of circuit board

For PCB electronic equipment industry, according to the industry survey, the most rapid weakness of the electronics tin coating is its easy decomposition (easy to be oxidized or deleted), poor solderability leads to welding difficulties, and high impedance leads to poor conductivity or poor overall circuit board efficiency Stable and easy to grow tin whiskers may cause short circuit of PCB circuit, even burn or fire

It is reported that the first research on electroless tin plating in China was conducted at Kunming University of Science and Technology in the early 1990s, followed by Guangzhou Tongqian Chemical (Enterprise) in the late 1990s. So far, the industry has recognized that these two organizations are the best. Among them, according to our contact screening investigation, experimental observation and long-term durability test of many companies, it is confirmed that the tin coating of the chemical industry before passing is a pure tin coating with low resistivity,

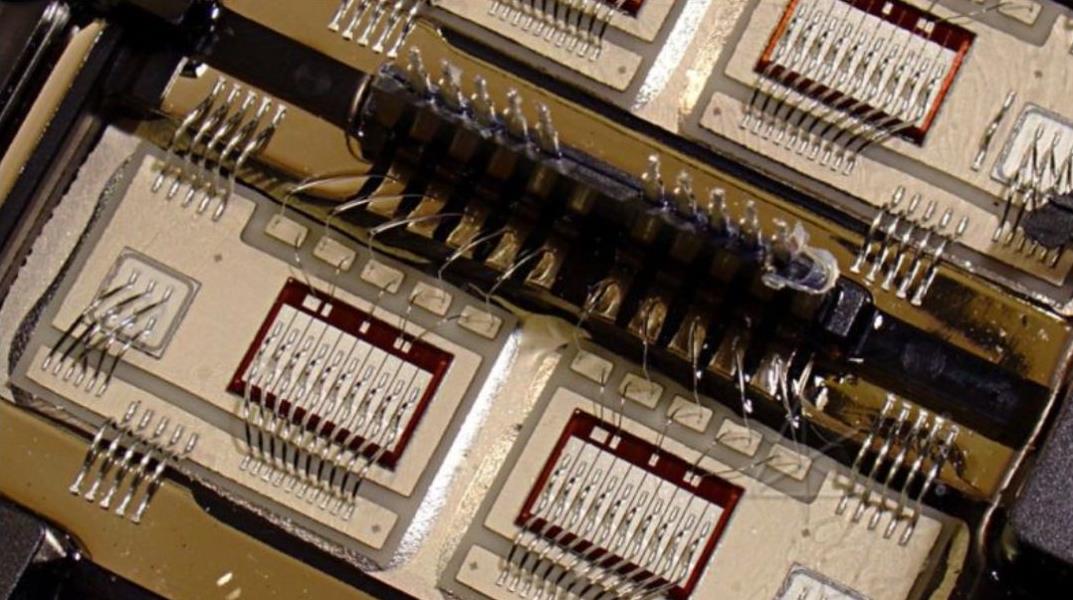

Circuit board

And it can ensure high level of conductivity and welding quality No wonder they dare to guarantee to the outside world that the coating can keep the color for one year without blistering, peeling, permanent tin whiskers, any sealing and anti discoloration protection

Later, when the whole social production industry developed to a certain extent, many subsequent participants often copied from each other In fact, a consistent number of companies themselves did not have the R&D or initiative capabilities themselves Therefore, many products and their users â Electronic products (circuit boards) The bottom of the board or the overall electronic product) performance is poor. The main reason for poor performance is PCB, because it is plated on PCB when unqualified chemical tin plating technology is used The tin is not really pure tin (or pure metal element), but a compound of tin (that is, it is a non metal substance)

Since the main circuit of PCB is copper foil, there is a tin coating on the solder joint of copper foil, and electronic components are welded on the tin coating through solder paste (or solder wire). In fact, the solder paste is melting. The welding state between the electronic components and the tin coating is metal tin (i.e. metal elements with good conductivity). It can be simply pointed out that the electronic components are connected to the copper foil at the bottom of the PCB through the tin coating. The purity and impedance of the tin coating instrument are the key; However, before inserting electronic components, when we directly use the instrument to detect impedance, in fact, both ends of the instrument probe (or called the test wire) first contact the copper foil at the bottom of the PCB. Then connect the tin coating on the surface to the copper foil at the bottom of the PCB to transfer the current. In this regard, tin plating is the key, the key to affect impedance, the key to affect the efficiency of the entire PCB, and the key that is easy to be ignored.

It is well known that, except for the simple substance of metal, its compounds are poor conductors, or even non-conductive (which is also the key to the distribution or expansion of capacity in the circuit). In addition, in the case of tin compounds or mixtures, there is such quasi conductivity rather than non-conductivity in the tin coating due to future oxidation or humidity, The existing resistivity or the resistivity after electrolytic reaction and the corresponding impedance are quite high (enough to affect the level or signal transmission in the digital circuit), and the characteristic impedance is inconsistent. This will affect the performance of the circuit board and the whole machine.

Therefore, as far as the current social production phenomenon is concerned, the coating materials and efficiency at the bottom of PCB are the most important and direct reasons that affect the characteristic impedance of PCB Volatility. In retrospect, the worrying influence of its impedance becomes more invisible and changeable The main reasons for its consideration are: first it cannot be seen by the taken eye (including its changes)

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.