The core PCB can be divided into core single panel, core double-sided board and core multilayer board according to the number of layers; It can be divided into flexible PCB board (flexible board), rigid PCB board and rigid flexible combination PCB board (rigid flexible combination board) according to the material. The printed circuit board is one of the important electronic components and the carrier of electronic components. Next, this article will briefly introduce these kinds of core board PCBs.

1、 According to the number of circuit layers, it can be divided into single panel, double panel and multilayer board. Common multilayer boards are generally 3-6 layers, and complex multilayer boards can reach more than ten layers.

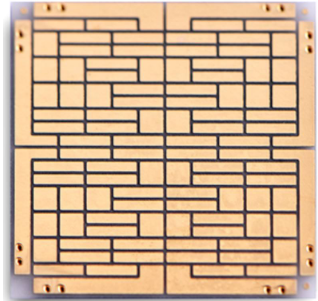

Core board

(1) Single panel

On the most basic printed circuit board, parts are concentrated on one side and wires are concentrated on the other side. Because the wires only appear on one side, the printed circuit board is called a single panel. Because there are many strict restrictions on the circuit of a single panel (because there is only one side, and the wiring cannot cross but must go around a separate path), early circuits used this type of circuit board

(2) Double-sided board

This circuit board has wiring on both sides. In order to connect the wires on both sides, proper circuit connections must be made between the two sides. Such connections between circuits are called pilot holes. The pilot hole is a small hole filled with or coated with metal on the printed circuit board, which can be connected with the wires on both sides. Because the area of the double-sided board is twice that of the single panel, and the wiring can be staggered (can be wound to the other side), the double-sided board can be used on circuits more complex than the single panel.

(3) Multilayer board

In order to increase the area of PCB wiring, more single or double sided wiring boards are used for multilayer boards. Several double-sided boards shall be used for multilayer boards, and a layer of insulating layer shall be placed between each layer of boards and then stuck firmly. The number of layers of the circuit board represents several independent wiring layers. Usually, the number of layers is even and includes the outermost two layers.

2、 According to the base material type of the core board, it is divided into flexible circuit board, rigid circuit board and rigid flexible combination board.

(1) (Flexible plate)

Flexible board is a printed circuit board made of flexible substrate, which has the advantage of being bendable and convenient for the assembly of electrical components. FPC has been widely used in aerospace, military, mobile communication, laptop, computer peripherals, PDA, digital cameras and other fields or products.

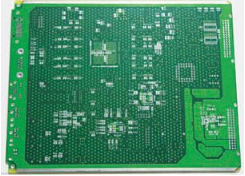

(2) Rigid PCB

It is made of paper base (commonly used for one side) or glass cloth base (commonly used for both sides and multiple layers), prepreg with phenolic or epoxy resin, and stick copper foil on one or both sides of the surface layer for lamination and curing. This kind of PCB copper-clad sheet is called rigid sheet. Then make a PCB. We call it the core PCB rigid board. It is a printed circuit board made of rigid substrate that is not easy to bend and has certain strength and toughness. Its advantage is that it can provide certain support for PCB components attached to it.

(3) Rigid flexible PCB board (rigid flexible PCB board)

Rigid flexible combination board refers to a printed circuit board containing one or more rigid areas and flexible areas, which is composed of rigid plates and flexible plates laminated together. The advantage of rigid flexible composite plate is that it can not only provide the support of rigid printed boards, but also has the bending characteristics of flexible boards, which can meet the requirements of three-dimensional assembly.