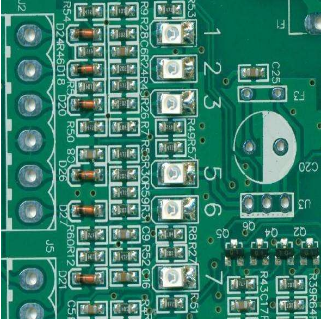

With the extensive implementation of lead-free PCB welding and its wide application in high reliability panels, especially in automobile panels, the proportion of tin deposition surface treatment is rising. Therefore, a better understanding of the characteristics of tin deposition surface treatment is of great significance to ensure the reliability of tin deposition panels. This article has referred to a large number of tin deposition materials, and based on practical experience, introduced the relevant quality characteristics of tin deposition in more detail, and also provided the improvement methods of the quality defects related to tin deposition, hoping to enable readers to better understand tin deposition and control the quality of tin deposition.

Tinplate

1 Principle of tin deposition The tin deposition reaction is the replacement reaction of tin and copper. Through the replacement reaction of tin ions and copper, tin is deposited on the copper surface to form a flat and bright metal tin layer. The reaction equation is as follows: Cu+Sn2+=Sn+Cu2+(1) Theoretically, the potential of copper (E0Cu2+/Cu=0.34 V) is higher than that of tin (E0Sn2+/Sn=-0.14V). Therefore, it is impossible for copper to replace tin. If you want to replace tin from copper, you must add copper ion complexing agents, such as thiourea Cyanide, etc., forms a stable complex with Cu2+to make the potential of copper move negatively, so as to achieve the purpose of tin deposition. Improper handling by the PCB manufacturer may cause many problems. During the manufacturing process of the double-sided window sinking tin plate with the plug hole, because the ink in the hole is attacked by the liquid medicine when the window opening position of the plug hole is developed, there are holes in the hole, oil and light transmission problems after the anti soldering. In the later process of tin deposition, because the holes in the hole are easy to remain liquid medicine, which will pollute the tin surface and cause the tin surface to be black, the defective scrap is extremely high when producing such plates. Fanyi PCB solved the problem of tin plate by further studying the characteristics of tin plate, and can conduct batch production of tin plate.

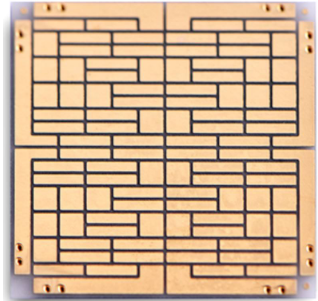

PCB proofing manufacturer: differences between FPC flexible circuit board and rigid circuit board

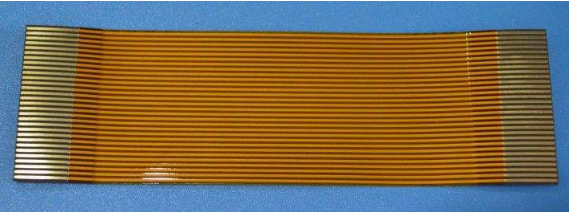

FPC belongs to a kind of printed circuit board, which is called FPC soft board. FPC generally uses PI as the base material, which can stop bending and flexure arbitrarily. PCB is the so-called rigid circuit board, which is usually called the hard board. Generally, FR4 is used as the base material, which cannot be bent or flexed. FPC flexible circuit boards are used for repeated flexure and the connection of some small parts. PCB rigid circuit boards are often used in some places that do not require flexure and are relatively hard.

FPC FPC is not only a circuit board that can be flexed, but also an important design method for connecting planar circuit structures. This structure can be used with other electronic product designs to build different applications. As for rigid PCB, unless the circuit is made flat by means of film filling, the PCB is generally flat. Therefore, FPC FPC is a good processing plan for electronic product design to make full use of plane space. At present, the common space extension plan for rigid PCB is to use slots and interface cards. FPC flexible PCB can make similar structures only in the way of switching design, and it is more flexible in directional design.

Flexible circuit board

FPC FPC flexible circuit board can use terminal connection to stop line connection, but it can also use soft and hard separation boards to avoid these connection mechanisms. With one piece of FPC connection, two hard boards can be connected into a group of parallel circuit systems, and can also be turned into any angle to adapt to different product shapes. A single FPC can use the planning method to configure many hard boards and connect them. This method reduces the interference of connectors and terminals, and can improve the signal quality and product trust.