The variety of plates with different thicknesses that can be provided for special plates is limited, so designers must consider the limitations of plate characteristic parameters and PCB processing technology in the process.

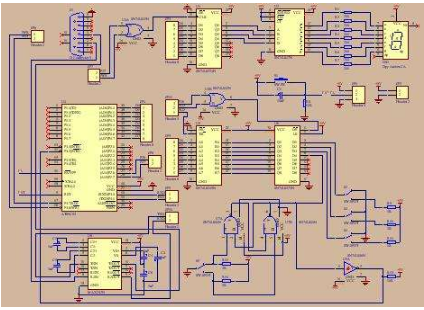

The materials have various thicknesses, and there are a wide range of plates suitable for multi-layer lamination. The following table gives a multilayer laminate structure and plate thickness distribution parameters, taking FR4 plate as an example, for reference by PCB design engineers.

FR4 plate

Comparison of main parameters and performances of PCB boards

The dielectric constant and loss factor are the most important parameters for PCB design and processing. For PCB multilayer board design, processing punching, laminating performance, etc. should also be considered when selecting the board.

Based on the above analysis of transmission line characteristic impedance, loss, propagation wavelength and comparison of plates, product design must consider cost and market factors.

Therefore, it is recommended that in PCB design, designers should consider the following key factors when selecting boards:

(1) Different working frequencies of signals have different requirements for plates.

(2) The FR4 board can be selected for PCB working below 1GHz, with low cost and mature multi-layer pressing process. If the signal input and output impedance is low (50 ohms), the transmission line characteristic impedance and line to line coupling need to be strictly considered when wiring. The disadvantage is that FR4 plates produced by different manufacturers and different batches have different doping, different dielectric constants (4.2-5.4) and are unstable.

(3) For optical fiber communication products operating at 622Mb/s or above and small signal microwave transceivers operating at 1G or above 3GHz or below, modified epoxy resin materials such as S1139 can be selected. Because its dielectric constant is relatively stable at 10GHz, its cost is low, and the multilayer pressing PCB process is the same as FR4. For example, such boards are recommended for 622Mb/s data multiplexing and branching, clock extraction, small signal amplification, optical transceiver, etc. to facilitate the production of multilayer boards, and the cost of boards is slightly higher than that of FR4 boards (about 4 minutes/cm2 higher). The disadvantage is that the thickness of base materials is not as complete as FR4 boards. Alternatively, RO4000 series such as RO4350 are used, but RO4350 double-sided boards are commonly used in China. Disadvantages: the number of different thickness varieties of these two kinds of boards is not complete, and it is not convenient to make multilayer printed PCB boards due to the thickness size requirements. For example, for RO4350, PCB manufacturers produce four kinds of plate thicknesses, including 10mil/20mil/30mil/60mil, while there are fewer domestic imports, which limits the laminate design.

(4) For large signal microwave circuits below 3GHz, such as power amplifiers and low-noise amplifiers, it is recommended to use double-sided plates similar to RO4350. RO4350 has stable dielectric constant, low loss factor, good heat resistance and processing technology comparable to FR4. Its plate cost is slightly higher than that of FR4 plate (about 6 points/cm2 higher).

(5) Microwave circuits above 10GHz, such as power amplifiers, low-noise amplifiers, up and down converters, have higher requirements for PCB boards. It is recommended to use double-sided boards with performance equivalent to F4.

(6) Multi layer PCB board for wireless phone requires low dielectric constant stability, low loss factor, low cost, and high dielectric shielding requirements. It is recommended to select a board with performance similar to PTFE (multi-purpose in the United States/Europe, etc.), or FR4 board and high-frequency board combined to form a low-cost, high-performance laminate.