The circuit board factory tells you something about making glue residue by micro slicing

Circuit board manufacturing, circuit board design, PCBA processing manufacturers will explain to you the little knowledge of micro chip making glue residue

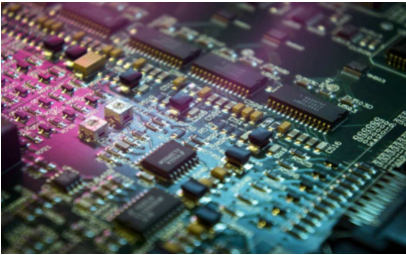

PCBA processing is to connect various electronic components on PCB board through surface mount (SMT), plug-in (DIP) and other electronic assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the small size and light weight of electronic products also have certain changes and requirements in mounting. The reliability, seismic resistance and excellent weldability of the products have high requirements for the hardware and software facilities of PCBA processing.

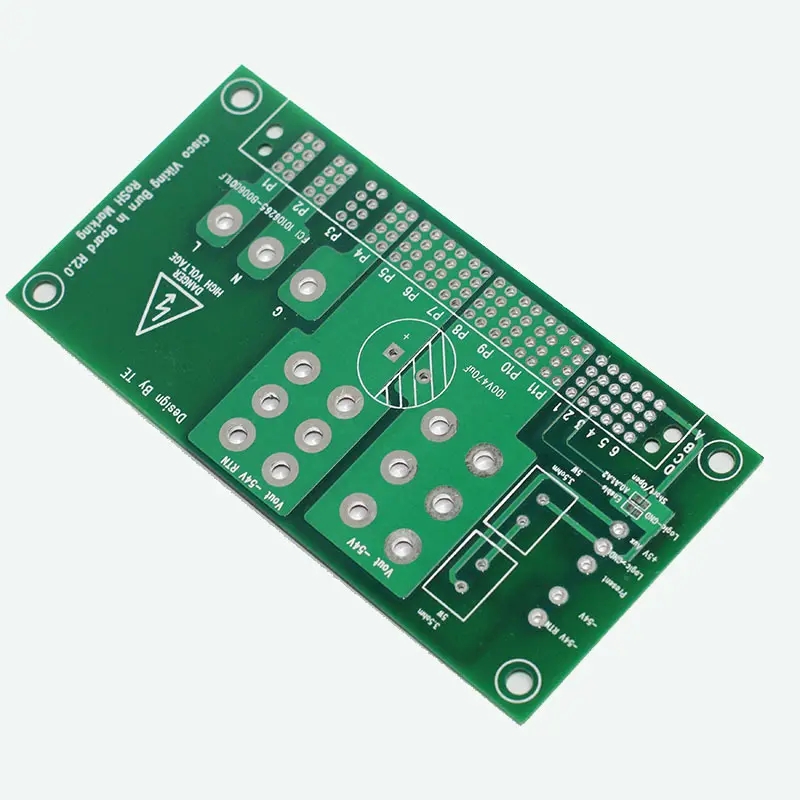

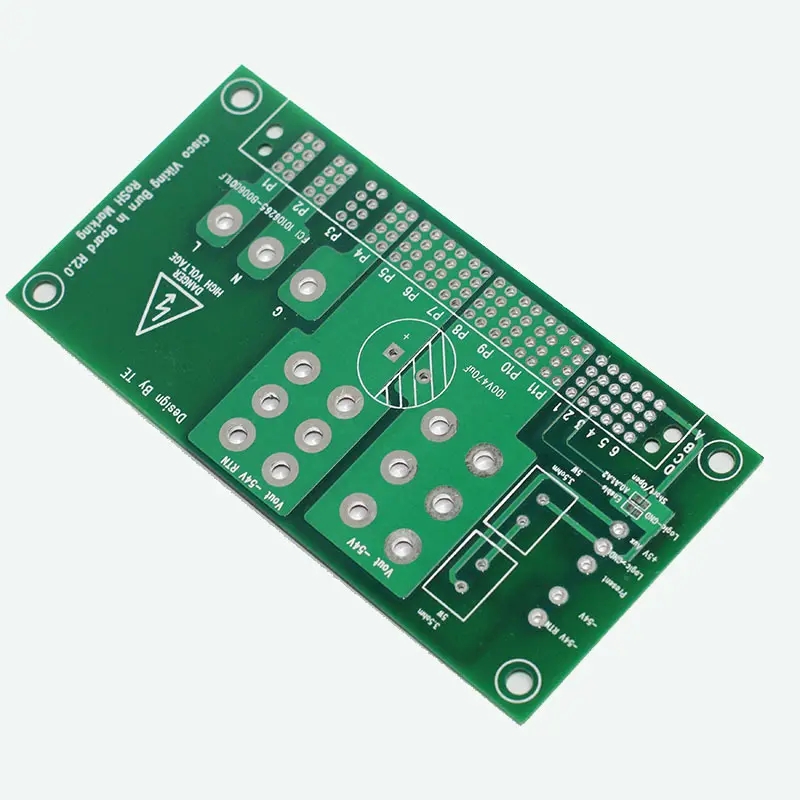

The circuit board factory belongs to a production type factory, and the quality problem of products has always been the focus of attention of manufacturers. The following small compilation will share with you the little knowledge of the circuit board factory in removing glue residue.

The circuit board factory tells you something about making glue residue by micro slicing

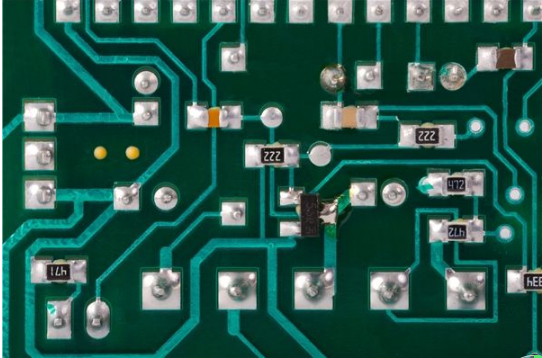

Since the Tg of FR-4 epoxy resin is about 130 ℃, and the temperature caused by the strong friction between the drill needle and the plate is very high during drilling, and because the glass fiber resin and Tungsten Carbide are both bad conductors, the accumulated heat often makes the instantaneous temperature of the hole wall reach more than 200 degrees centigrade, which inevitably makes part of the resin soften and become a paste, and the hole wall is coated with the rotation of the drill needle, The side copper surface of each inner hole ring is also inevitable. After cooling, it turns into Smear, which forms an obstacle in the "interconnection" between the hole ring and the copper wall later. This is known to all in the industry. The "separation" caused by Smear cannot enter sand in the eyes of major circuit board manufacturers. Of course, circuit board manufacturers will pay attention to these problems, The glue removal slag is to ensure the quality.

The circuit board factory tells you something about making glue residue by micro slicing

The glue removal slag process has been valued by people in circuit board factories for decades, and domestic manufacturers have much experience in mass production in this regard. However, taking the motherboard as an example, an average of 5000 holes are drilled for each piece, and it is inevitable that there will be occasional misses during the wiring processing of the large row of boards in the wet process. The wet method or chemical oxidation method is used to remove the glue residue on the hole wall. From the concentrated sulfuric acid method and dichromate method in the early years to the current "bulking+potassium permanganate" method, it can be said that all kinds of formulas have reached the acme. After years of training, the field analysis and control technology has also found a direction, that is, to closely monitor the tank liquid, and immediately replace the tank liquid to ensure the due yield before it is too bad, In this way, there are few real glue residue failures, and our circuit board manufacturers can rest assured.

Circuit board manufacturing, circuit board design, PCBA processing manufacturers will explain to you the small knowledge of micro chip making glue residue.